Pheasant feed with effects of fast growth realization and high disease resistance, and preparation method thereof

A production method and a pheasant technology, which are applied in the field of feed, can solve the problems of weak disease resistance of pheasants, slow growth rate of pheasants, chicken residues, etc., so as to enhance the overall disease resistance ability, enhance the disease resistance ability, and improve the fresh flavor. Tao effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

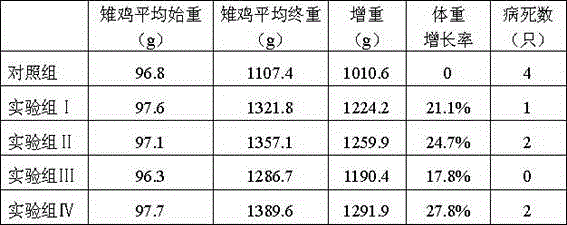

Examples

Embodiment 1

[0040] 1000kg pheasant feed making process of the present invention is as follows:

[0041] S100: Take 370kg of soybeans and stir-fry until they are 9 mature;

[0042] S200: Combine the above 9 mature soybeans with 430kg of corn, 50kg of cooked rapeseed meal, 9kg of wheat bran, 26kg of calcium grains, 35kg of lard, 10kg of pepper, 20kg of garlic, 7kg of angelica, 10kg of Codonopsis pilosula, 5kg of wolfberry, and 7.5kg of astragalus , 9kg Scutellaria baicalensis, 8kg jujube, 3.5kg tangerine peel composition of Chinese medicine additives in the container after manual stirring and mixing to obtain mixed raw materials for subsequent use;

[0043] S300: Take the mixed raw material obtained in step S200 and put it into a pulverizer for pulverization, and then pass through an 80-mesh screen to obtain a screened material;

[0044] S400: Using the feed pellet machine to make the sieved material obtained above into pellet feed with a particle diameter of 3 mm;

[0045] S500: take the...

Embodiment 2

[0047] 1000kg pheasant feed making process of the present invention is as follows:

[0048] S100: Take 400kg of soybeans and stir-fry until they are 9 mature;

[0049] S200: Combine the above 9 mature soybeans with 400kg of corn, 60kg of cooked rapeseed meal, 10kg of wheat bran, 25kg of calcium grains, 35kg of lard, 10kg of pepper, 20kg of garlic, 2kg of salt, 5kg of angelica, 8kg of Codonopsis pilosula, and 3.2kg of Chinese wolfberry , 6kg Radix Astragali, 6kg Radix Scutellariae, 6.8kg Red Dates, 3kg dried orange peel are mixed in the blender and dropped into pulverizer to pulverize to obtain mixed raw materials for subsequent use;

[0050] S300: Put the mixed raw material obtained in step S200 into a pulverizer for pulverization, and then pass through a 60-mesh screen to obtain a screened material;

[0051] S400: Making the sieved material obtained above with a feed pellet machine into pellet feed with a particle diameter of 4 mm;

[0052] S500: take the above granular feed ...

Embodiment 3

[0054] 1000kg pheasant feed making process of the present invention is as follows:

[0055] S100: Take 330kg of soybeans and stir-fry them until they are 9 mature;

[0056] S150: Take 24kg of garlic and mash it, take 12kg of chili and cut it into sections, take 6kg of angelica, 8.5kg of Codonopsis pilosula, 3.5kg of Qiqi, 6.3kg of astragalus, 8.2kg of scutellaria baicalensis, 2.5kg of tangerine peel, mix and grind, add 6.5kg of red date powder to form 41.5kg Chinese medicine additives;

[0057] S200: Put the above 9 mature soybeans, 450kg of corn, 60kg of fermented rapeseed meal, 10kg of wheat bran, 35kg of calcium grains, 35kg of lard, 2.5kg of salt, as well as the above crushed garlic, pepper segments and traditional Chinese medicine additives in a mixer After stirring and mixing, put it into a pulverizer and pulverize to obtain the mixed raw material for subsequent use;

[0058] S310: put the above mixed raw materials into a pulverizer for pulverization, and then pass thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com