Natamycin microemulsion and preparation method thereof

A natamycin and microemulsion technology, applied in the preservation of food ingredients as antimicrobial, food science, food preservation, etc., can solve the problems of increasing workload, limiting the scope of application, etc. Strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

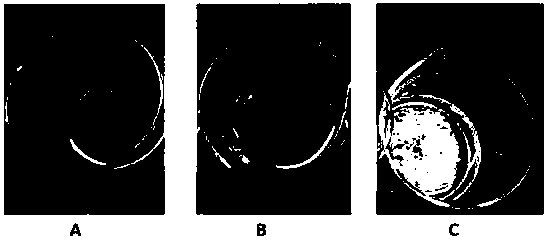

Image

Examples

Embodiment 1

[0023] 1) Accurately weigh 1.0 g of natamycin and add it to 100 mL of water, and stir on a magnetic stirring table so that the natamycin is evenly distributed in the water (that is, it is equivalent to adjusting its pH to 7).

[0024] 2) Accurately weigh 12.5g of skimmed milk (80% casein content) into 200mL water, stir and distribute evenly, then add 0.1mol / L NaOH solution to adjust its pH to 11.

[0025] 3) Mix the substances treated in step 1) and step 2), and stir at 80°C to form a clear solution.

[0026] 4) At this point, transfer the above-mentioned clear solution to a cold water bath at 0-10°C to continue stirring, and slowly add 1% citric acid solution to the above-mentioned clear solution dropwise to adjust the pH of the solution to 7. 5min, continue stirring for 30min to obtain natamycin microemulsion.

[0027] 5) Place the microemulsion at room temperature at 25°C for 24 hours, then measure the particle size of the microemulsion on a Malvern laser particle size ana...

Embodiment 2

[0030] The difference from Example 1 is that in step 1), 0.1 mol / L NaOH solution was added to adjust the pH to 11 and the total volume of the solution was 100 mL. Steps 2) to 4) and 6) are the same as in Example 1. The particle size distribution D value of the natamycin microemulsion measured in step 5) is 98.56±9.32nm, and the PDI is 0.321±0.05.

Embodiment 3

[0032] Step 1) is the same as step 1) in Example 1, and step 2) is basically the same as step 6) in Example 1, except that the natamycin suspension is sucked.

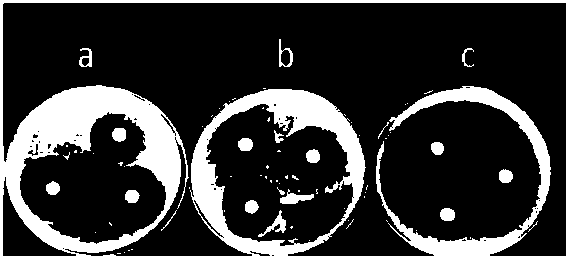

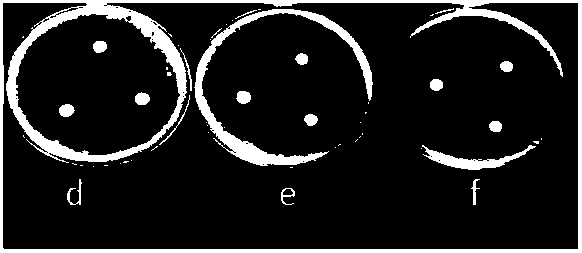

[0033] Table 1 Inhibitory effects of the forms of natamycin on the production of mold and yeast

[0034]

[0035] Note: Marked with the same letter means that the difference is not significant (p>0.05) level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com