Novel sulfhydrylization graphene oxide and iron and manganese oxide composite material for removing methylmercury in water body and preparation method

A technology of iron-manganese oxide and composite materials, which is applied in the field of water treatment, can solve the problems of poor adsorption effect of methylmercury and achieve remarkable effects and simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

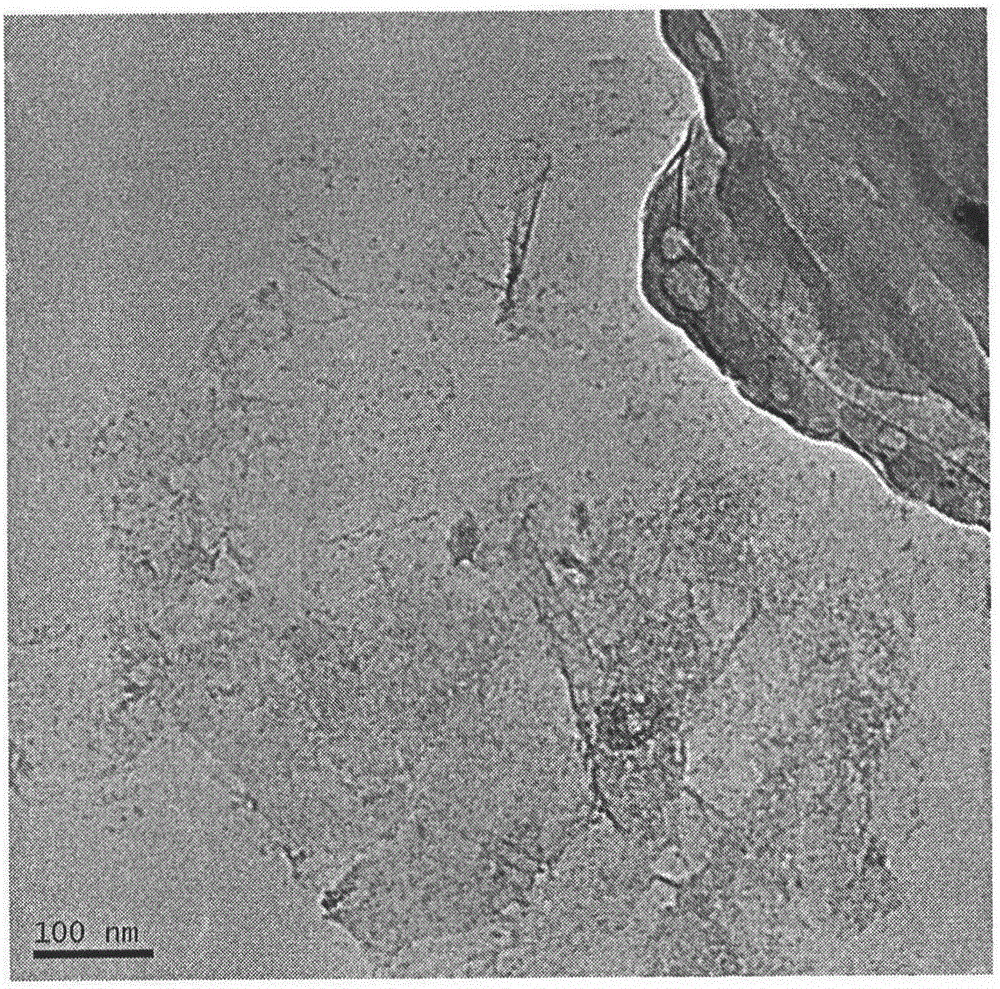

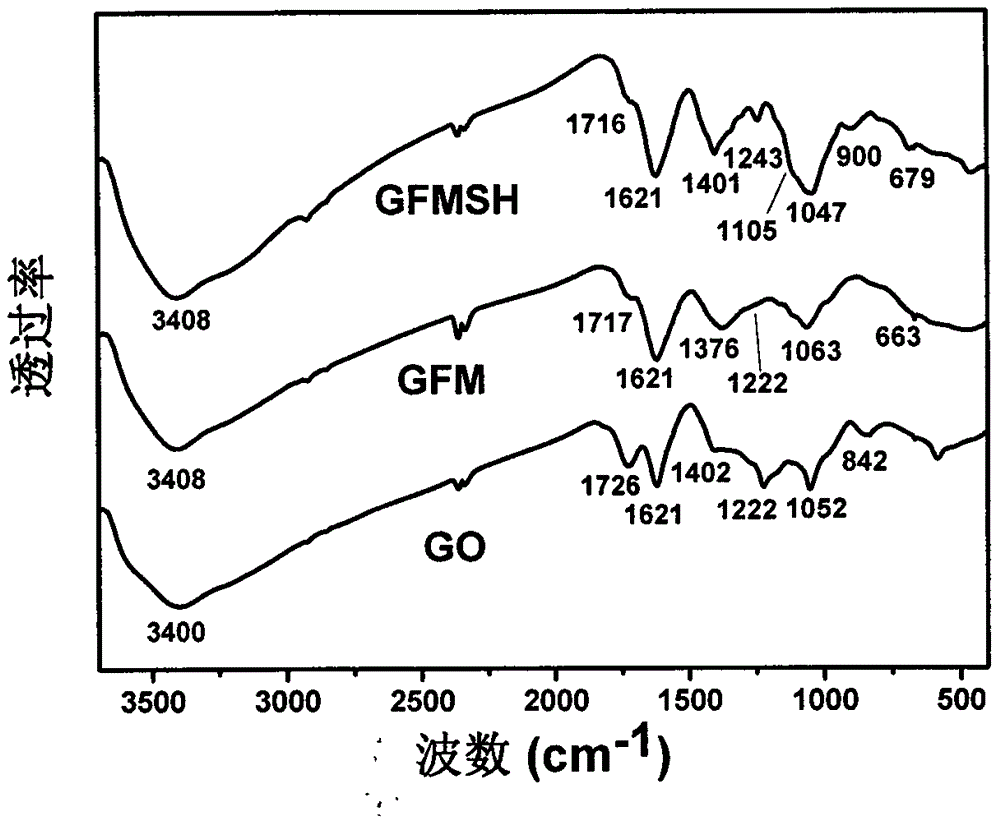

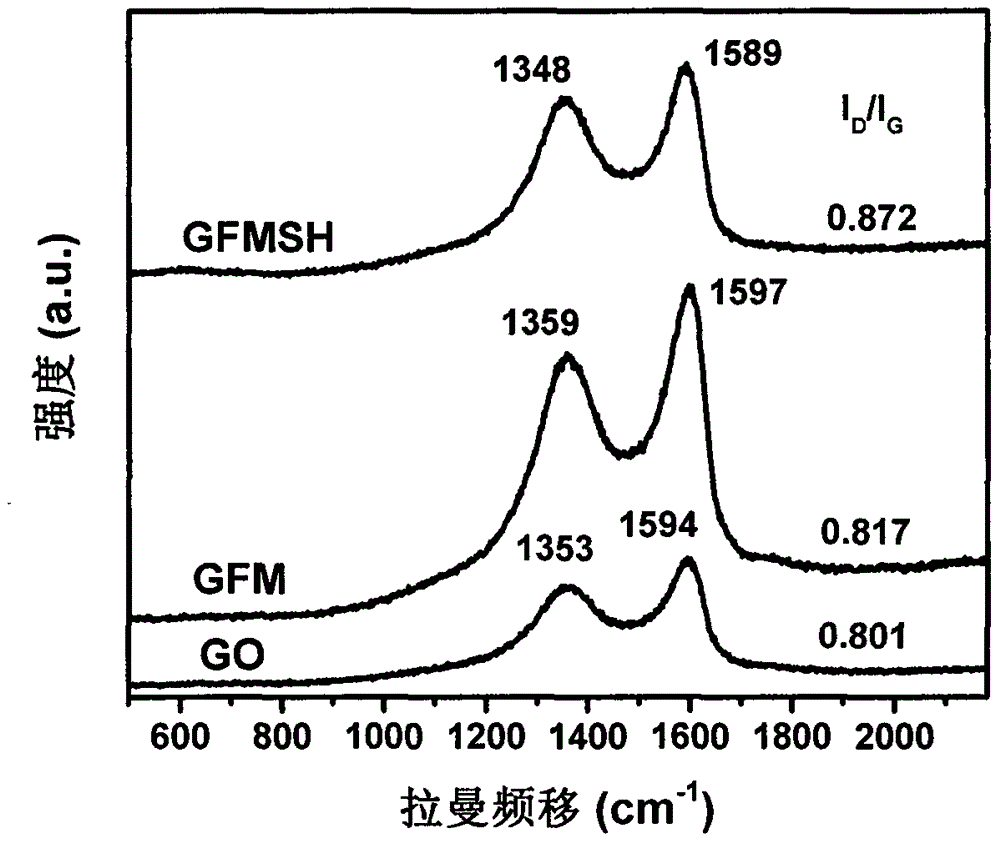

[0015] This implementation provides a simple and convenient preparation method of a novel mercaptolated graphene oxide / iron manganese oxide composite material, and applies it to the adsorption of methylmercury in water. The preparation procedure of the novel mercaptolated graphene oxide / iron-manganese oxide composite material is simple: add ferrous sulfate and potassium permanganate solution (Mn / Fe molar ratio is 0.33, Fe / GO mass ratio 1 / 7.5), mix and adjust the pH to 7.5, stir, stand still, wash with water until neutral, and freeze-dry to obtain graphene oxide / iron manganese oxide composite material powder. Weigh 150mg graphene oxide / iron manganese oxide powder, wash 3 times with ethanol (200mL), then disperse in toluene (30mL) by ultrasonic (300W) for 1 hour, wash 3 times with ethanol (200mL) and disperse in 300mL 2 % 3-mercaptopropyltrimethoxysilane (95% ethanol) solution and stirred for 6 hours, then adjusted to pH 9.5 with ammonia water and continued to stir for 24 hours,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com