Honeycomb de-nitration catalyst suitable for high-arsenic fume and preparation method of honeycomb de-nitration catalyst

A denitration catalyst and honeycomb technology, which is applied in the field of denitration catalysts, can solve the problems such as the inability to meet the guaranteed value of the chemical life of the SCR denitration catalyst, affecting the normal production and operation of thermal power plants, and catalyst poisoning, so as to facilitate continuous production and improve resistance to arsenic poisoning. Ability, the effect of preventing poison inactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

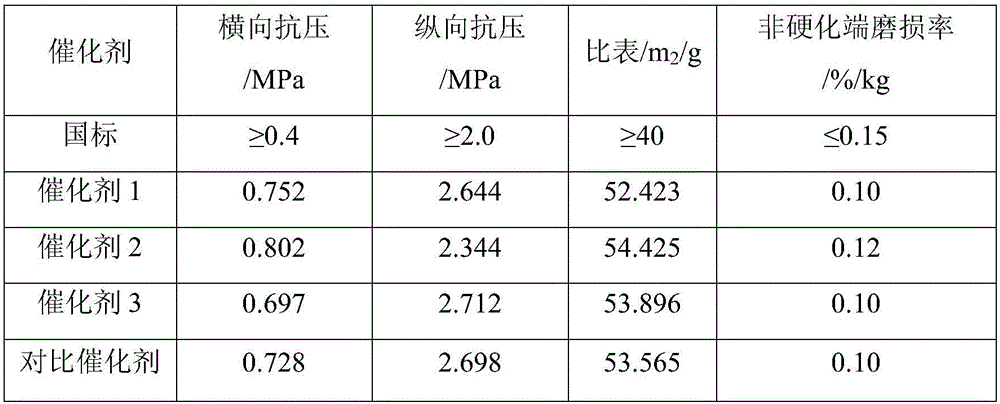

Examples

Embodiment 1

[0027] A honeycomb denitrification catalyst suitable for high arsenic flue gas, the components by weight include: TiO 2 86 copies, MoO 3 5 copies, V 2 O 5 1 part, SiO 2 4 parts, 2 parts of organic additives, 1 part of inorganic structural additives, 1 part of monoethanolamine.

[0028] The preparation method of the above catalyst is as follows:

[0029] (1) Combine 86 parts of titanium dioxide, ammonium heptamolybdate (with MoO 3 Mass basis) 5 parts, ammonium metavanadate (in V 2 O 5 Mass) 1 part, glass fiber (in SiO 2 By mass) 4 parts, 2 parts of hydroxymethyl cellulose ammonium and polyethylene fiber, 1 part of USY molecular sieve (Si / Al=25-100), 1 part of monoethanolamine, supplemented with appropriate amount of water, ammonia and lactic acid After mixing for 4 hours, the moisture content is 28.67%, the pH value is 8.76, and the ductility is 0.4987;

[0030] (2) Extruding the material of step (1) to obtain an 18-hole honeycomb catalyst;

[0031] (3) Dry the honeycomb catalyst of...

Embodiment 2

[0037] A honeycomb denitrification catalyst suitable for high arsenic flue gas, the components by weight include: TiO 2 79 copies, MoO 3 7 copies, V 2 O 5 1.5 parts, SiO 2 4 parts, 4 parts of organic additives, 3 parts of inorganic structural additives, 1.5 parts of monoethanolamine.

[0038] The preparation method of the above catalyst is as follows:

[0039] (1) Mix 79 parts of titanium dioxide, ammonium heptamolybdate (with MoO 3 Mass) 7 parts, ammonium metavanadate (in V 2 O 5 Mass basis) 1.5 parts, silica sol (in SiO 2 By mass) 4 parts, 4 parts of hydroxymethyl cellulose ammonium and polyethylene fiber, 3 parts of natural zeolite, 1.5 parts of monoethanolamine, supplemented by appropriate amount of water, ammonia and lactic acid for 4.5 hours, the moisture content after mixing is 26.54% , PH value is 8.51, ductility is 0.5642;

[0040] (2) Extruding the material of step (1) to obtain an 18-hole honeycomb catalyst;

[0041] (3) Dry the honeycomb catalyst of step (2) at 50°C for...

Embodiment 3

[0047] A honeycomb denitrification catalyst suitable for high arsenic flue gas, the components by weight include: TiO 2 84 copies, MoO 3 5 copies, V 2 O 5 1 part, SiO 2 4 parts, 5 parts of organic additives, 0 parts of inorganic structural additives, 1 part of monoethanolamine.

[0048] The preparation method of the above catalyst is as follows:

[0049] (1) Combine 84 parts of titanium dioxide, ammonium tetramolybdate (with MoO 3 Mass basis) 5 parts, vanadyl sulfate (in V 2 O 5 Mass) 1 part, white carbon black (by SiO 2 By mass) 4 parts, 5 parts of hydroxymethyl cellulose ammonium, polyethylene fiber, polypropylene fiber, 1 part of monoethanolamine, supplemented with appropriate amount of water, ammonia and lactic acid for mixing for 3 hours, the water content after mixing is 27.65%, pH The value is 8.61 and the ductility is 0.5348;

[0050] (2) Extruding the material of step (1) to obtain an 18-hole honeycomb catalyst;

[0051] (3) Dry the honeycomb catalyst of step (2) at 70°C f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com