A method and device for laser shot peening of aircraft wings

A technology of laser peening forming and laser peening, which is applied in the field of mechanical engineering, can solve the problems of unsuitable large-size parts, etc., and achieve the effects of improving precision, simple device, and easy control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

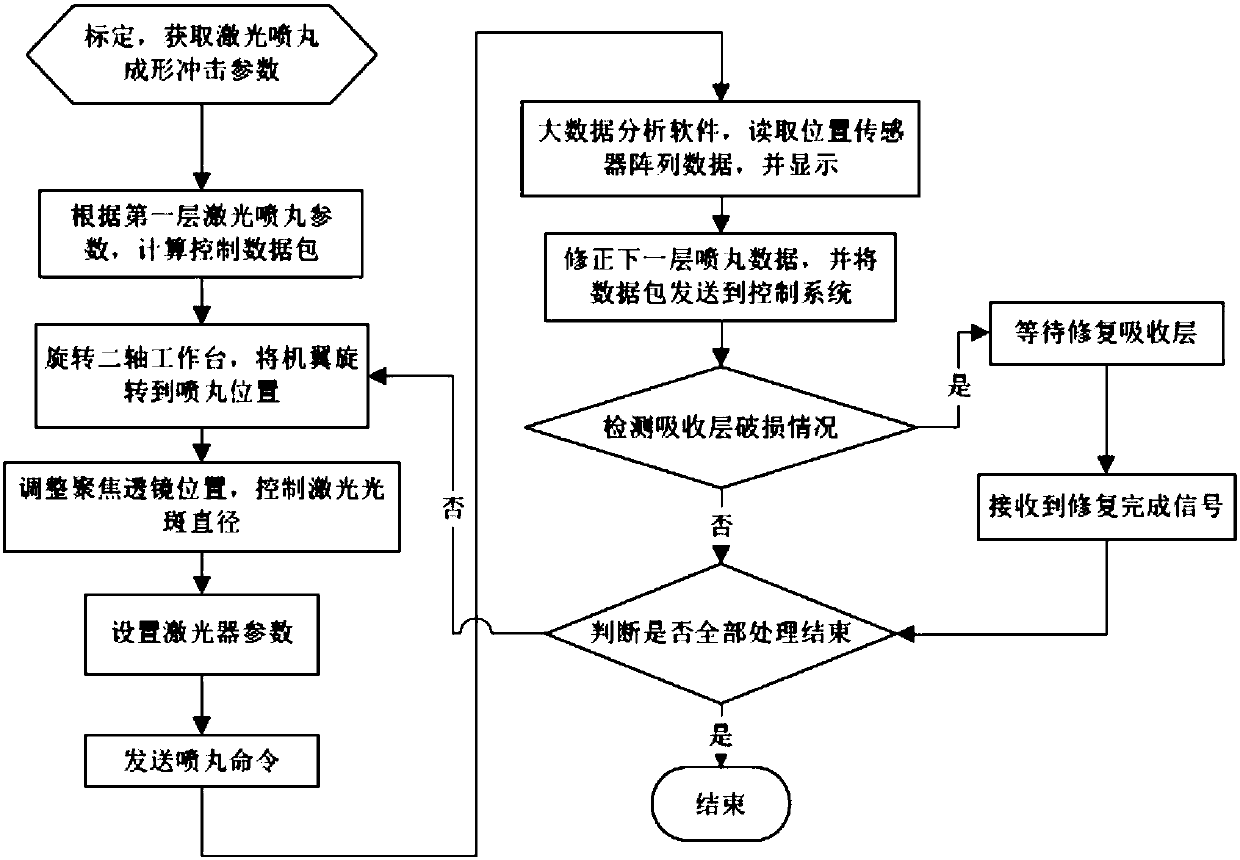

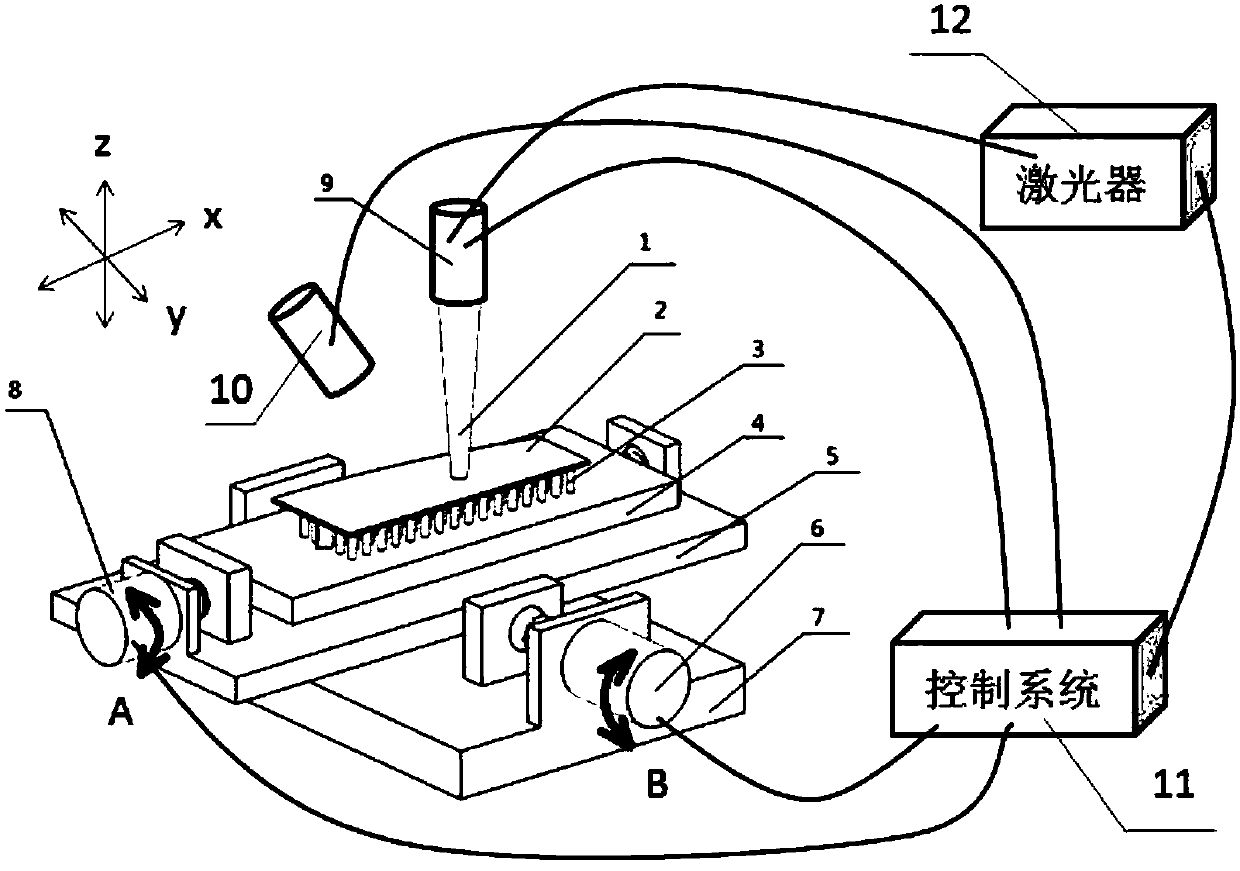

[0045] In this embodiment, the invention provides a method for impact forming of an aircraft wing, the flow chart of which is as follows figure 1 shown, including the following steps:

[0046]Step 1: Calibrate the aircraft wing to obtain the layered impact parameters of laser peening. First, the big data software reads the 3D model data of the aircraft wing parts and the blank, and interpolates the machining allowance between the aircraft wing parts and the blank according to the elastic-plastic properties of the material to obtain the laser shot peening layered data; Secondly, the big data analysis system plans a variety of laser peening trajectories and processing parameters on each layer, and generates simulation files that can be recognized by finite element analysis software, such as the INP file format that can be recognized by Abaqus software. Call the finite element simulation software to calculate and analyze the simulation file; read the calculation results of the f...

Embodiment 2

[0079] The present embodiment provides a kind of aircraft wing impact forming method, it is characterized in that, comprises the following steps:

[0080] Step 1: Calibrate the aircraft wing to obtain the layered impact parameters of laser peening;

[0081] Step 2: The big data analysis system calculates the laser peening control data packet according to the first-layer layered impact parameters, and sends the data packet to the control system;

[0082] Step 3: The control system controls the two-axis workbench to rotate the aircraft wing to the impact position according to the information in the data packet;

[0083] Step 4: The control system moves the lens assembly to the peening position according to the information in the data packet, and adjusts the focus lens position of the lens assembly, and adjusts the laser spot diameter;

[0084] Step 5: the control system sets the first layer of laser peening parameters according to the information in the data packet;

[0085] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com