Method for simply preparing Au-Ag dual-metal nanoparticle film of meshed structure

A bimetallic nano, network structure technology, applied in nanotechnology, metal processing equipment, transportation and packaging, etc., can solve the problems of large size of hollow nanoparticles and uneven network structure formation, and achieve good stability and reaction conditions. Gentle, simple and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Synthesis of Ag-containing Au seeds

[0031] Add 0.5mL 0.01mol / L silver nitrate aqueous solution, 1.5mL 0.01mol / L tetrachloroalloy acid aqueous solution, 1mL 0.01mol / L sodium citrate aqueous solution into 60mL deionized water, stir at room temperature for 30 minutes, and then 2.6 mL of freshly prepared 0.01 mol / L sodium borohydride aqueous solution was added dropwise, and stirring was continued for 4 hours after the dropwise addition to obtain a wine-red dispersion, that is, Ag-containing Au seeds.

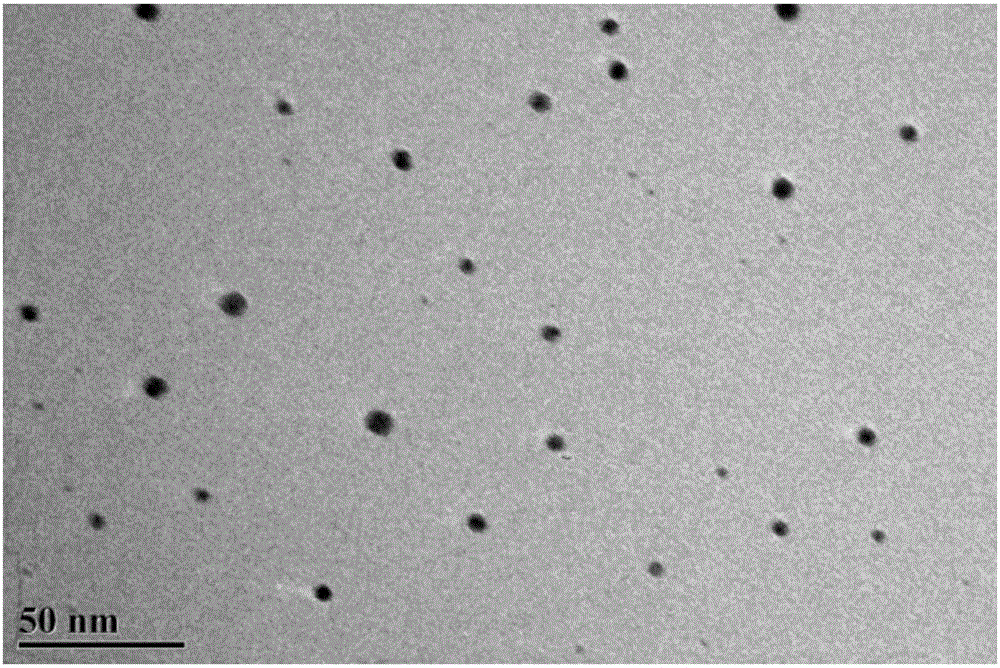

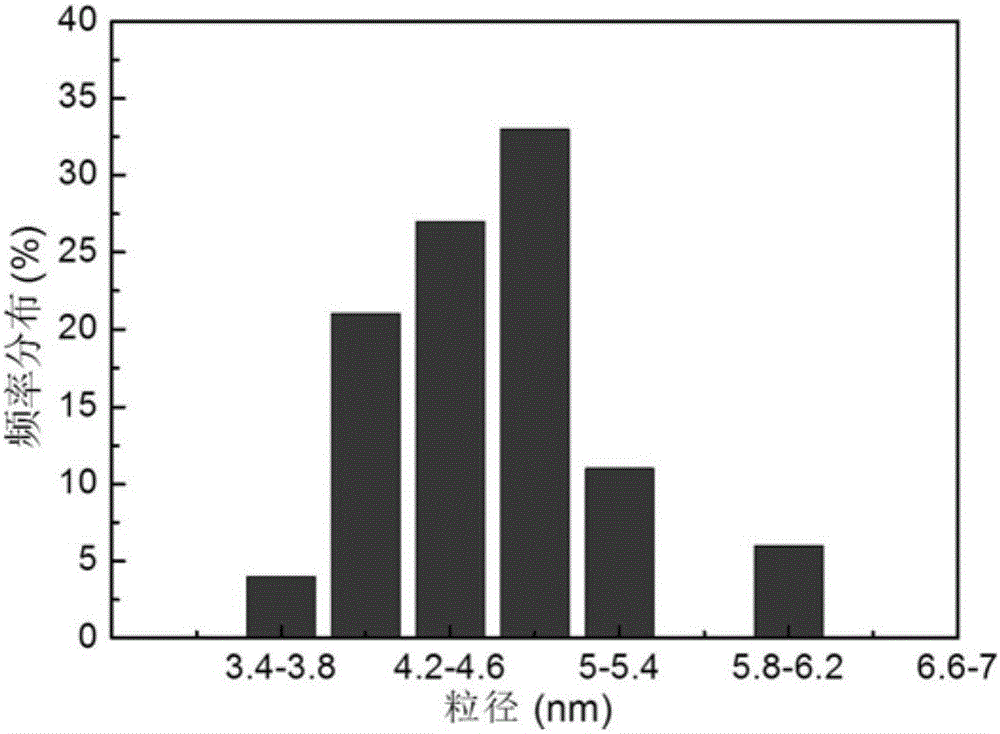

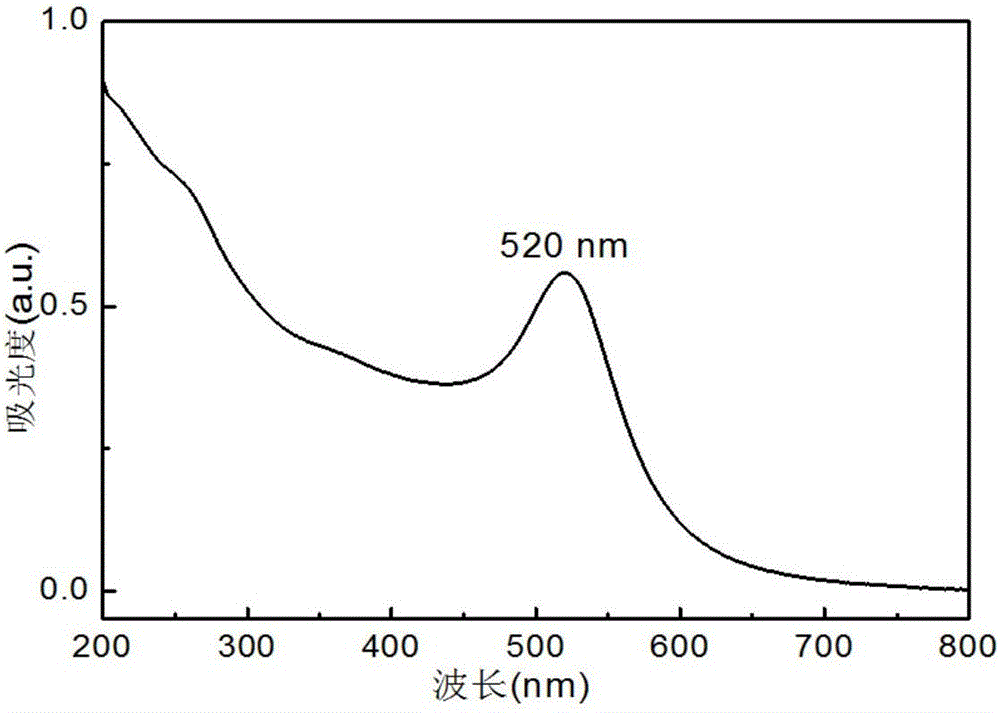

[0032] Adopt JEM-2100 type transmission electron microscope and U-3900 / 3900H type (Japan Hitachi) ultraviolet-visible spectrophotometer to carry out characterization to gained sample, the result sees Figure 1~3 . Depend on Figure 1~2 It can be seen that the Ag-containing Au seeds have uniform size and good monodispersity, and the particle size is about 3-5 nm. image 3 The surface plasmon resonance absorption peak of nano-Au appears at 520nm in the ultraviolet-visib...

Embodiment 2

[0037] Step 1 of this embodiment is the same as that of Embodiment 1. In step 2 of preparing the Au-Ag bimetallic nanoparticle film, add 15 mL of Ag-containing Au seeds obtained in step 1 into 16 mL of 0.0006 mol / L silver nitrate aqueous solution, and add 2 mL of 0.1 mol / L ascorbic acid aqueous solution, and stir at room temperature In 10 minutes, a layer of Au-Ag bimetallic nanoparticle film was formed at the water-air interface (see Figure 9 ).

Embodiment 3

[0039] Step 1 of this embodiment is the same as that of Embodiment 1. In step 2 of preparing the Au-Ag bimetallic nanoparticle film, 15mL of the Ag-containing Au seeds obtained in step 1 were added to 16.5mL of 0.0009mol / L silver nitrate aqueous solution, and 3mL of 0.1mol / L ascorbic acid aqueous solution was added. Stir for 10 minutes to form a layer of Au-Ag bimetallic nanoparticle film at the water-air interface (see Figure 10 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com