Preparation method of laboratory BGA nanometer reinforced solder balls and heat fatigue-resistance BGA packing devices

A solder ball and laboratory technology, applied in the direction of welding equipment, welding medium, manufacturing tools, etc., can solve the problems of poor fatigue resistance and achieve the effect of low cost and convenient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034]A preparation of BGA reinforced solder balls with nanoparticles (POSS particles), base material SAC305 lead-free eutectic powder, adding 3% POSS nanoparticles, mechanical stirring and mixing for half an hour, and then mixing with 60 rpm The powder was high-energy ball milled for 10 hours to obtain a certain physical combination.

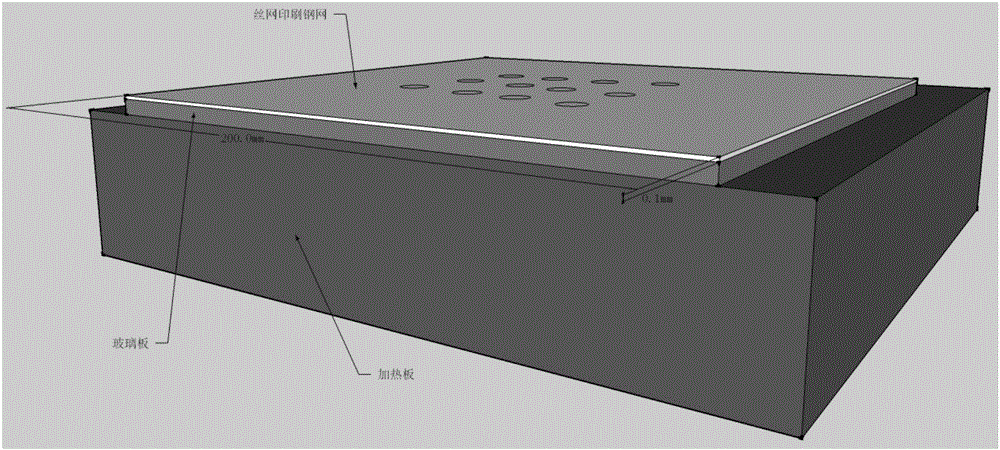

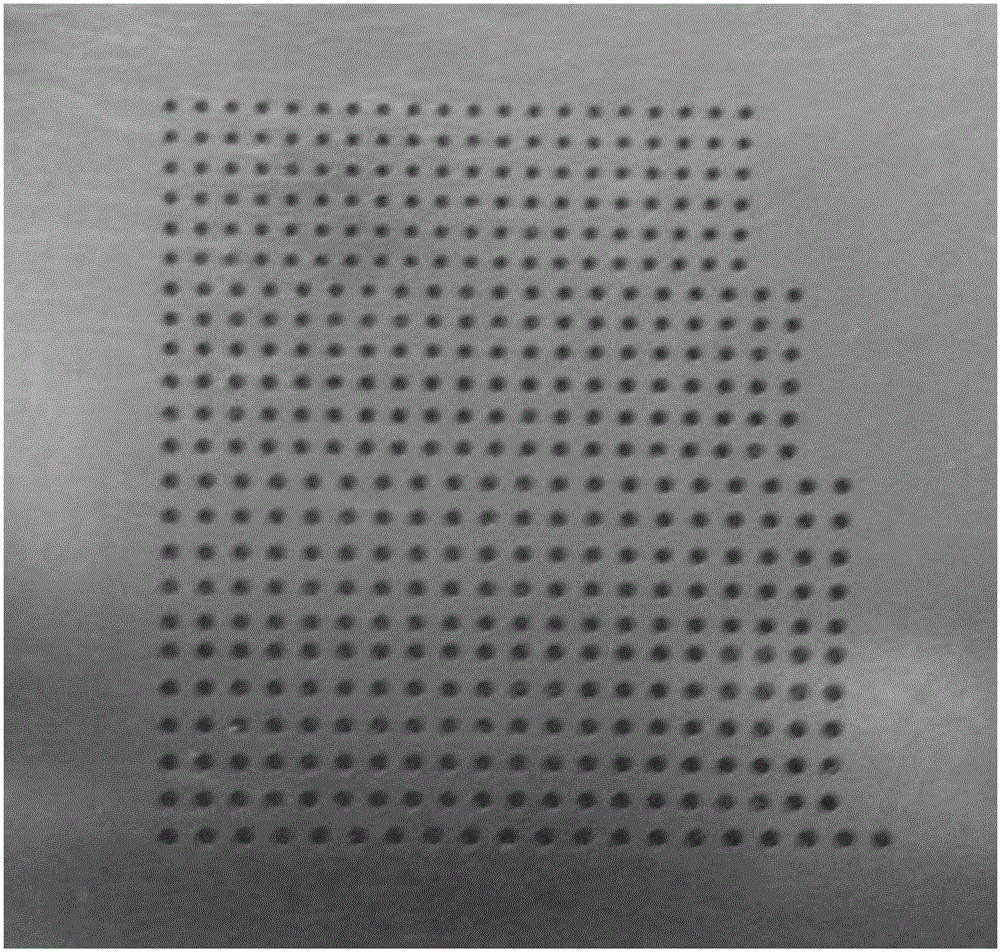

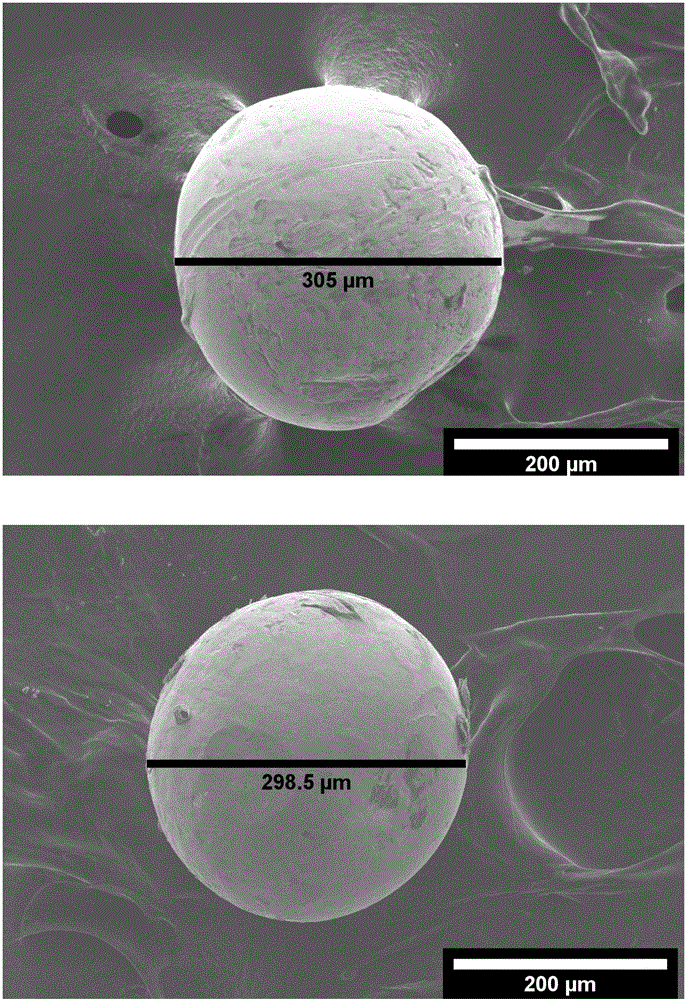

[0035] Mix the composite powder and rosin-type soldering paste at a mass ratio of 88:12, add in grades, stir mechanically for half an hour, mix evenly, and store in the refrigerator. Then use the next figure 2 The diameter is 0.48mm, the thickness is 0.1mm steel mesh round hole, and the glass plate is bonded to form an integrated device (as shown figure 1 ), apply a small amount of compound solder paste on the steel plate, and brush it on the glass plate through the mesh holes of a specific area with a scraper, and then put the steel mesh-glass plate on a heating plate with a temperature of 240°C and keep it warm for 10s , Then take it off t...

Embodiment 2

[0042] In order to observe the good connection effect and weldability, SEM microscopic morphology observation was carried out on the solder joint section. Figure 4 (a) is the package solder joint prepared by using standard commercially available SAC305 solder balls, (b) is the package solder joint prepared by this patent using solder balls added with 3% POSS in SAC305, (c) is the package solder joint prepared in SAC305 The packaging solder joints prepared by adding 0.05% CNTs solder balls in the package have a multiple of 300 times, which is 50 times smaller than the previous two multiples. It is found that the solderability is good and the size is not much different.

Embodiment 3

[0044] The BGA solder ball developed by the present invention is prepared by mesh printing with composite solder paste. Since the effect of adding nanoparticles in the composite solder paste directly determines the effect of adding nanoparticles in BGA solder joints, it is therefore used in lapped Cu Apply a small amount of solder paste on the chip to prepare simulated solder joints, and conduct electron microscope observation at 2000 times. Figure 5 Among them, (a) is the unadded SAC305 solder joint, (b) is the composite solder joint with 3% POSS added, and (c) is the composite solder joint with 0.05% CNTs added. It can be seen that the microstructure is refined, And the effect of adding nanoparticles is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com