A kind of anticorrosion treatment process of sorghum straw

A technology for sorghum straw and anti-corrosion treatment, which is applied in wood treatment, pretreatment equipment, wood treatment details, etc., can solve the problems of poor anti-corrosion effect, uneven strength, and poor economic benefits of woven products, and achieves complete functions and improved drying. Efficiency and loss rate reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] A process for antiseptic treatment of sorghum stalks, comprising the steps of:

[0029] (1) Straw pretreatment: remove the leaves, roots and shoots of freshly harvested sorghum straw 2, and then classify them according to the similarity of height and thickness of sorghum straw 2;

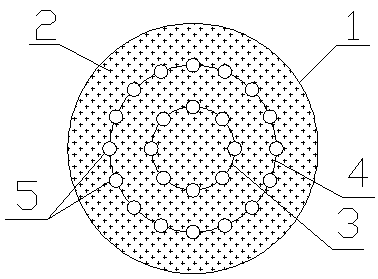

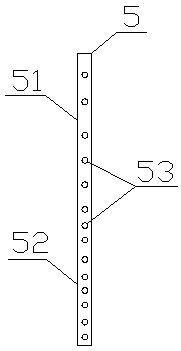

[0030] (2) Preparation of straw bales: The sorghum straws 2 treated in step (1) are bundled in groups of the same type to make straw bales 1 for later use. The cross-sectional shape of the straw bales 1 is circular. When the straw 2 is bundled, a ventilation pipe 5 is also arranged inside it. The ventilation pipe 5 is divided into an inner layer pipe 3 and an outer layer pipe 4 according to the position. The cross-sectional shape of the two pipes is circular. The pipe 3 is located at 1 / 3 of the radius of the straw bale, the outer tube 4 is located at 2 / 3 of the radius of the straw bale, and the length of the ventilation pipe 5 is not less than the average height of the straw bale 1;

[0031]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com