Comprehensive treatment and recycling method for chlorobenzene waste liquor and waste residues

A kind of technology of comprehensive treatment, chlorinated benzene

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

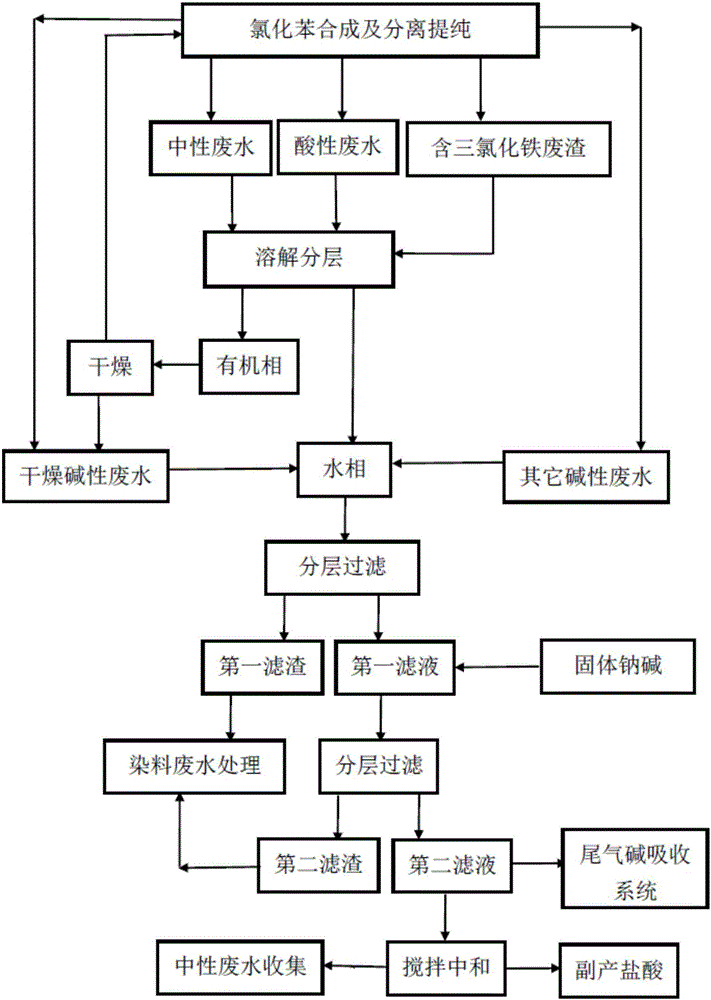

[0039] Embodiment 1: refer to simultaneously figure 1

[0040](1) Firstly, the acidic waste liquid (pH8) generated during the production of chlorinated benzene were collected separately. The acidic waste liquid was mainly It is the waste acid at the bottom of the chlorinated benzene chlorinator, the acid liquid produced by the absorption of water in the chlorination tail gas, the waste acid liquid produced by the by-product hydrochloric acid post, and the acidic cleaning liquid of other equipment; the alkaline waste liquid is mainly the tail gas alkali absorption Alkaline wastewater collected by the system, waste lye produced by drying raw materials and products, or alkaline discharge of other equipment. 4 tons of acid waste liquid collected and 1 ton of neutral waste liquid are mixed to obtain 5 tons of acid waste water with an acid value of 3.2%; then 5 tons of 3.2% acid water are added to 10 tons of ferric chloride-containing waste residue, The main component is 55.0% fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com