Microcrystalline glass with mechanoluminescence and preparation method thereof

A glass-ceramics and luminescence technology, applied in the field of glass-ceramics, can solve the problems of being unable to meet the various luminescence requirements of mechanoluminescent sensor displays, the color of luminescence and the limitation of the wavelength width of luminescence, etc., so as to facilitate large-scale promotion, The effect of low price and wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] In this embodiment, the steps for preparing glass-ceramics by the high-temperature melting method and the heat treatment method are as follows:

[0033] (1) Select high purity Na 2 CO 3 , SiO 2 , Ga 2 O 3 , ZnO, MnCO 3 As a raw material, the molar ratio between the raw materials is controlled to Na 2 CO 3 : SiO 2 : Ga 2 O 3 : ZnO: MnCO 3 =5:55:23:16.9:0.1;

[0034] (2) Weigh 40 grams of each raw material according to the ratio described in step (1), grind it in an agate grind for 40 minutes, and then place it in a platinum crucible at 1600°C for 1 hour. Pour the molten glass solution on a copper plate and flatten it with another copper plate, then transfer it to a muffle furnace and keep it at 500°C for 3 hours, then turn off the power supply of the muffle furnace and let the glass drop to room temperature with the furnace. The color is brown glass.

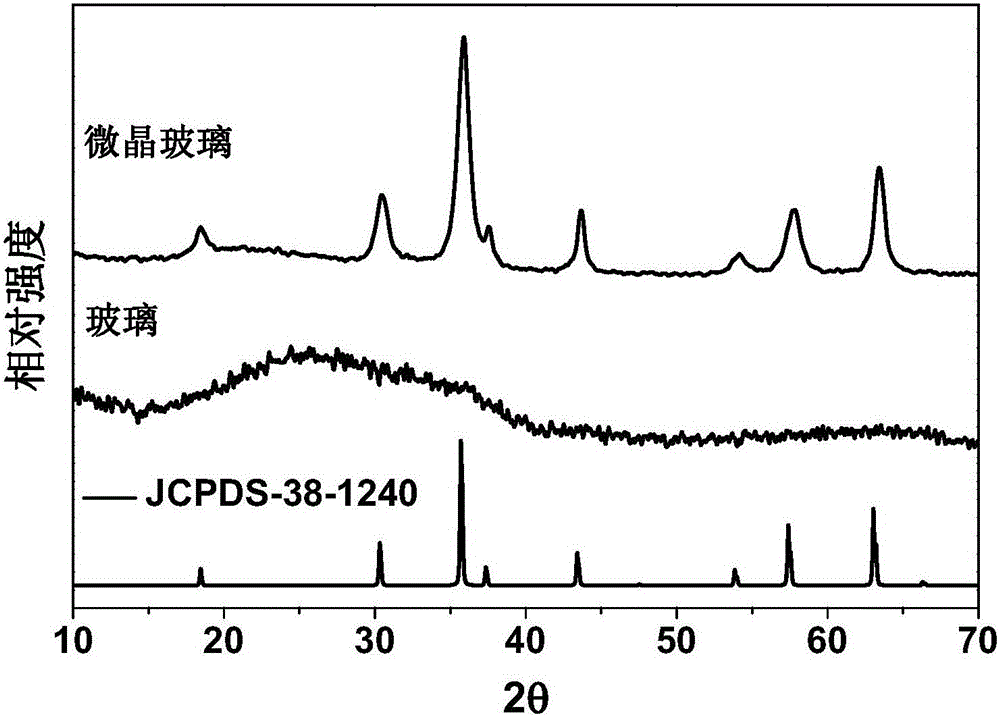

[0035] (3) Put the glass into the muffle furnace, raise the temperature from room temperature to 900°C at a heating rate of 20...

Embodiment 2

[0040] In this embodiment, the steps for preparing glass-ceramics by the high-temperature melting method and the heat treatment method are as follows:

[0041] (1) Select high purity Na 2 CO 3 , SiO 2 , Al 2 O 3 , ZnO, MnCO 3 As a raw material, the molar ratio between the raw materials is controlled to Na 2 CO 3 : SiO 2 : Al 2 O 3 : ZnO: MnCO 3 =5:55:23:16.9:0.1;

[0042] (2) Weigh 40 grams of each raw material according to the ratio described in step (1), grind it in an agate grind for 40 minutes, and then place it in a platinum crucible at 1600°C for 1 hour. Pour the molten glass solution on a copper plate and flatten it with another copper plate, then transfer it to a muffle furnace and keep it at 500°C for 3 hours, then turn off the power supply of the muffle furnace and let the glass drop to room temperature with the furnace. The color is brown glass. Put the glass into the muffle furnace, raise it from room temperature to 900°C at a heating rate of 200°C / h, keep it for 2h, t...

Embodiment 3

[0044] (1) Select high purity Na 2 CO 3 , SiO 2 , Al 2 O 3 , Ga 2 O 3 , ZnO, MnCO 3 As a raw material, the molar ratio between the raw materials is controlled to Na 2 CO 3 : SiO 2 : Al 2 O 3 : Ga 2 O 3 : ZnO: MnCO 3 =5:55:13:10:16.9:0.1;

[0045] (2) Weigh 40 grams of each raw material according to the ratio described in step (1), grind it in an agate grind for 40 minutes, and then place it in a platinum crucible at 1600°C for 1 hour. Pour the molten glass solution on a copper plate and flatten it with another copper plate, then transfer it to a muffle furnace and keep it at 500°C for 3 hours, then turn off the power supply of the muffle furnace and let the glass drop to room temperature with the furnace. The color is brown glass. Put the glass into the muffle furnace, raise it from room temperature to 900°C at a heating rate of 200°C / h, keep it for 2h, then turn off the muffle furnace power supply and let the glass cool to room temperature along with the furnace to obtain transp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com