A kind of high energy storage density dielectric ceramic material and preparation method thereof

A technology of high energy storage density and dielectric ceramics, applied in the direction of ceramics, inorganic insulators, etc., can solve the problems of unfavorable device stability, large temperature changes, high energy storage density, etc., to reduce dependence, low capacitance temperature coefficient, improve Effect of Dielectric Strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

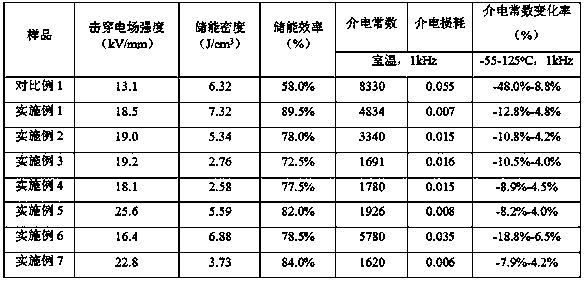

Embodiment 1

[0038] A method for preparing a high energy storage density dielectric ceramic material, the specific steps are:

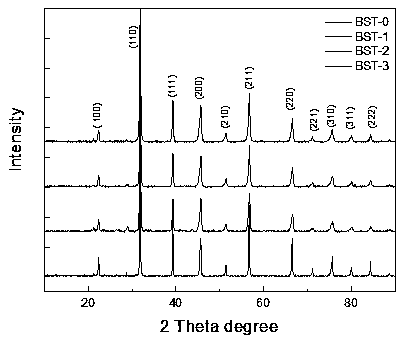

[0039] (1) Ba 1-x Sr x TiO 3 (x=0.1-0.5) Synthesis of Ceramic Powder

[0040] According to Ba 1-x Sr x TiO 3 (x=0.1, 0.2, 0.3, 0.4, 0.5) weigh BaCO 3 , SrCO 3 and TiO 2 Powder, the weighed powder is ball milled in deionized water for 24 hours, wherein the ball milling medium is zirconia balls, the ball / material mass ratio is 2:1, the tank volume is 1 / 2 of the tank volume, and the ball milling speed is 250 rpm minutes; the mixed slurry after ball milling was dried and pre-fired in an alumina crucible at 1150°C for 2 hours to obtain Ba 0.9 Sr 0.1 TiO 3 、Ba 0.8 Sr 0.2 TiO 3 、Ba 0.7 Sr 0.3 TiO 3 、Ba 0.6 Sr 0.4 TiO 3 and Ba 0.5 Sr 0.5 TiO 3 These 5 single-phase powders;

[0041] (2) Preparation of MAS glass powder

[0042] According to 15% MgO, 35% Al 2 o 3 , 50% SiO 2 The mass ratio of MgO, Al 2 o 3 and SiO 2 , the weighed powder was ba...

Embodiment 2

[0049] A method for preparing a high energy storage density dielectric ceramic material, the specific steps are:

[0050] (1) Ba 1-x Sr x TiO 3 (x=0.1-0.5) Synthesis of Ceramic Powder

[0051] According to Ba 1-x Sr x TiO 3 (x=0.1, 0.2, 0.3, 0.4, 0.5) weigh BaCO 3 , SrCO 3 and TiO 2 Powder, the weighed powder is ball milled in alcohol for 24 hours, wherein the ball milling medium is corundum balls, the ball to material mass ratio is 1:1, the tank volume is 1 / 2 of the tank volume, and the ball milling speed is 250 rpm; ball milling The final mixed slurry was dried and pre-fired in an alumina crucible at 1150°C for 2 hours to obtain Ba 0.9 Sr 0.1 TiO 3 、Ba 0.8 Sr 0.2 TiO 3 、Ba 0.7 Sr 0.3 TiO 3 、Ba 0.6 Sr 0.4 TiO 3 and Ba 0.5 Sr 0.5 TiO 3 These 5 single-phase powders;

[0052] (2) Preparation of MAS glass powder

[0053] According to 13wt% MgO, 32wt% Al 2 o 3 , 55wt% SiO 2 The ratio of weighing MgO, Al 2 o 3 and SiO 2 , the weighed powder was ball ...

Embodiment 3

[0060] A method for preparing a high energy storage density dielectric ceramic material, the specific steps are:

[0061] (1) Ba 1-x Sr x TiO 3 (x=0.1-0.5) Synthesis of ceramic powder

[0062] According to Ba 1-x Sr x TiO 3(x=0.1, 0.2, 0.3, 0.4, 0.5) weigh BaCO 3 , SrCO 3 and TiO 2 Powder, the weighed powder is ball milled in alcohol for 24 hours, wherein the ball milling medium is agate balls, the mass ratio of balls to material is 3:1, the filling capacity is 1 / 2 of the tank volume, and the ball milling speed is 250 rpm; ball milling The final mixed slurry was dried and pre-fired in an alumina crucible at 1150°C for 2 hours to obtain Ba 0.9 Sr 0.1 TiO 3 、Ba 0.8 Sr 0.2 TiO 3 、Ba 0.7 Sr 0.3 TiO 3 、Ba 0.6 Sr 0.4 TiO 3 and Ba 0.5 Sr 0.5 TiO 3 These 5 single-phase powders;

[0063] (2) Preparation of MAS glass powder

[0064] According to 18wt% MgO, 25wt% Al 2 o 3 , 57wt% SiO 2 The ratio of weighing MgO, Al 2 o 3 , SiO 2 , the weighed powder was bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy density | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com