Method for catalytic humification of sludge organic matter

A technology of organic matter and humification, applied in the field of sludge resource utilization, to achieve the effects of saving operating costs, accelerating humification, and increasing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

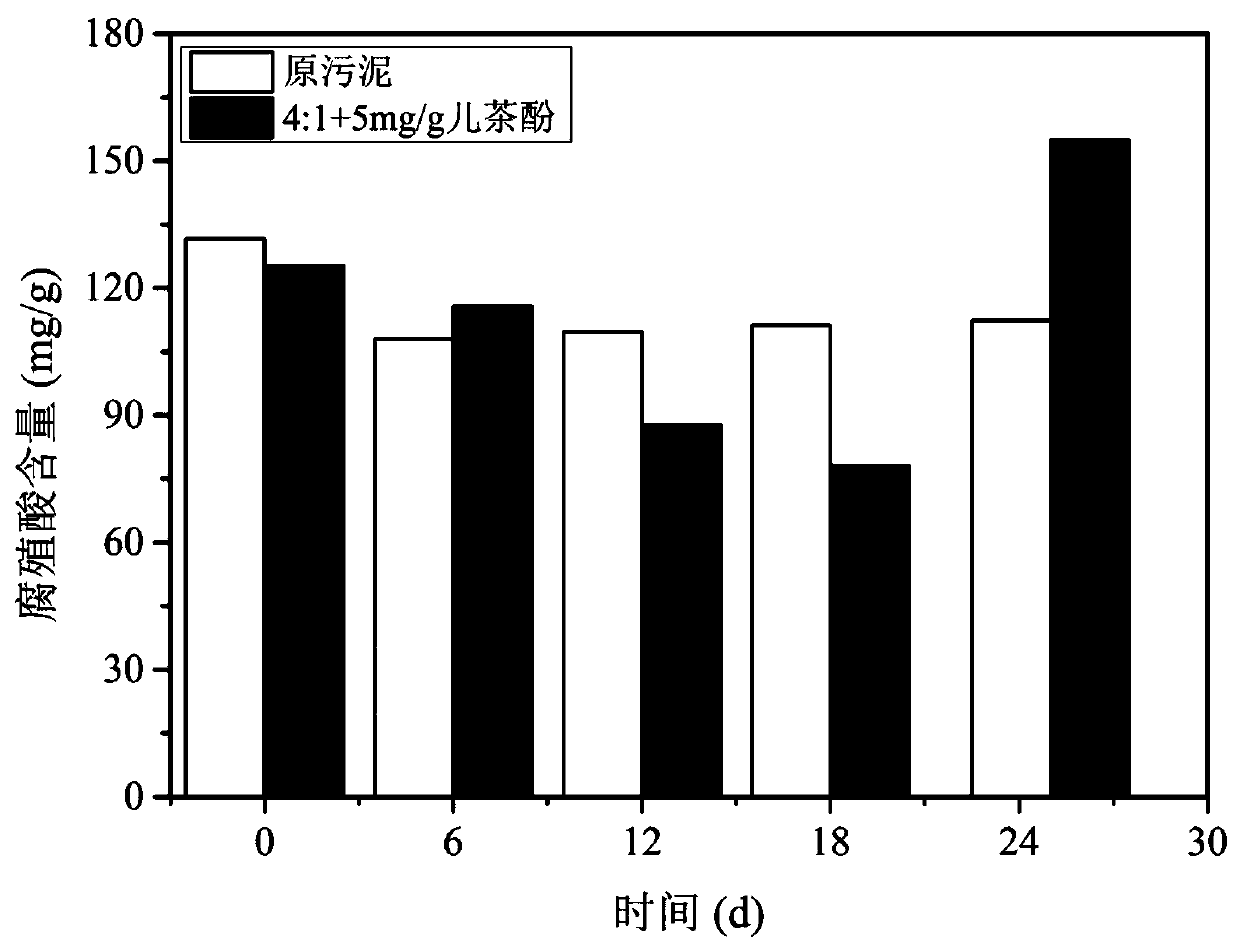

[0047] Embodiment 1, take pig iron scrap as catalyst, catechol is the sludge catalytic humification of precursor additive

[0048] 1. The amount of catechol added is 5mg / g sludge dry basis

[0049] (1) Raw material and formula

[0050] The moisture content of dewatered municipal sludge is about 80%, and the organic matter (volatile solid) content is about 55% (dry basis).

[0051] The materials were prepared according to the following formula, the total material of each formula was 100kg: pig iron filings: dehydrated municipal sludge = 4:1; the amount of catechol added was 5mg / g sludge dry basis.

[0052] (2) Method

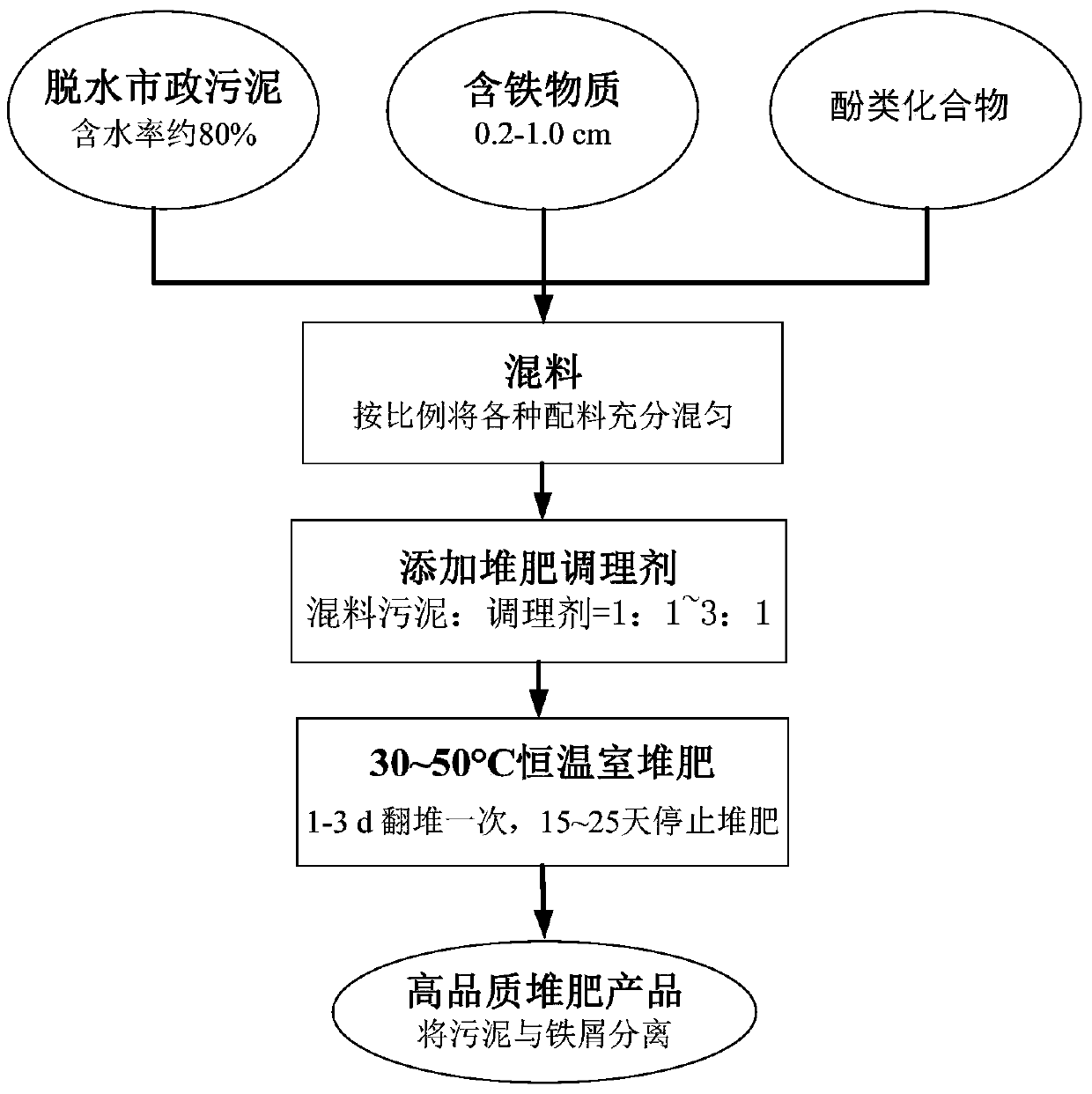

[0053] according to figure 1 The process flow chart shown carries out the catalytic humification of sludge, and the specific steps are as follows:

[0054] 1) The material is crushed, and the particle size of pig iron chips after crushing is 0.2-0.5cm;

[0055] 2) mixing materials, according to the ratio of the above formula, fully mixing the dehydrated muni...

Embodiment 2

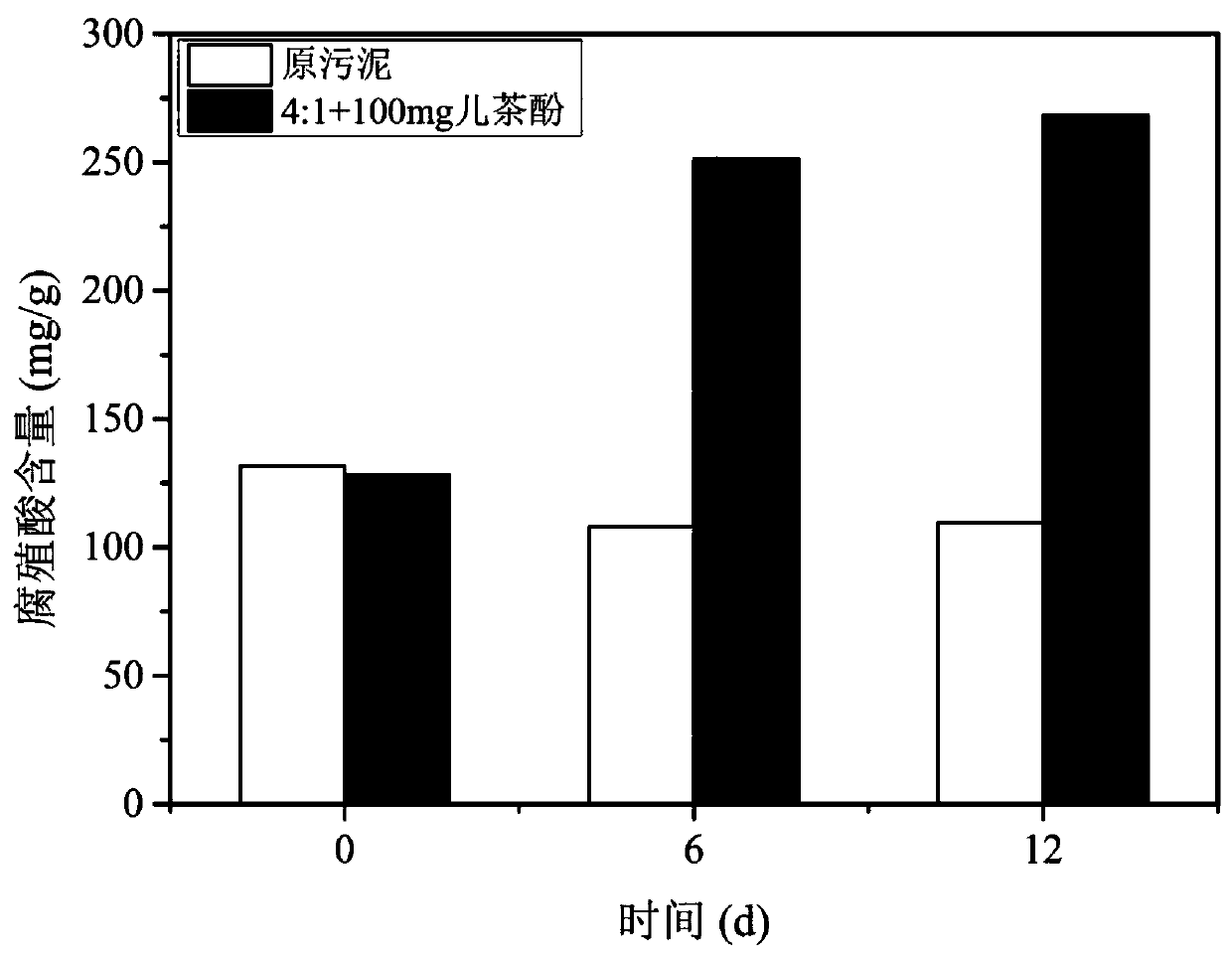

[0062] Embodiment 2, the sludge catalytic humification with iron oxide and catechol as additives

[0063] (1) Raw material and formula

[0064] The moisture content of dewatered municipal sludge is about 80%, and the organic matter content is about 55% (dry basis).

[0065] Prepare the materials respectively according to the following formula, each formula has a total material of 100kg: dehydrated municipal sludge: iron oxide = 10:1; the amount of catechol added is 100mg / g sludge dry basis.

[0066] (2) Method

[0067] according to figure 1 The process flow chart shown carries out the catalytic humification of sludge, and the specific steps are as follows:

[0068] 1) The material is crushed, and the particle size of iron oxide chips after crushing is 0.2-0.5cm;

[0069] 2) mixing materials, according to the ratio of the above formula, fully mixing the dehydrated municipal sludge, iron oxide and catechol to obtain the mixed materials;

[0070] 3) Mix the mixed material wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com