Recycling of aquaculture wastewater with low emissions from large-scale pig farms and manure enzymatic hydrolysis and microaerobic composting

A technology for breeding sewage and composting method, applied in the field of composting, can solve the problems of high organic content in pig manure, burning crop roots, generating certain heat, etc., so as to improve the rate of hydrolysis and fermentation, the effect is good, and the humification is strengthened. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

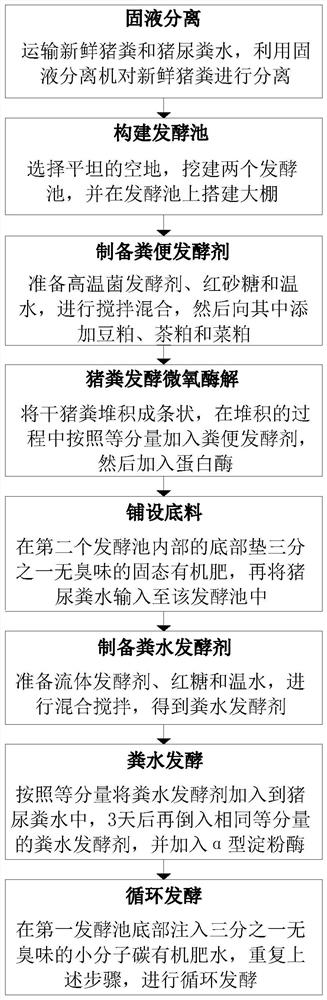

[0037] according to figure 1 As shown, this embodiment proposes a low-emission breeding sewage resource and manure enzymatic microaerobic composting method for large-scale pig farms, including the following steps:

[0038] Step 1: Solid-liquid separation

[0039] Directly transport fresh pig manure and pig urine and feces water from the pigsty, use a solid-liquid separator to separate the solid and liquid from the fresh pig manure so that it does not contain urine, and control the water content of the pig manure at 20%-40% to obtain dried pig manure;

[0040] Step 2: Build the fermentation tank

[0041] Choose a flat open space, dig and build two fermentation tanks, control the internal volume of each fermentation tank to be able to absorb 20-25 days of fresh pig manure or pig urine and feces, and build a greenhouse on the fermentation tank, covering the greenhouse with 3 layer insulation film;

[0042] Step 3: Prepare the Fecal Fermentation Agent

[0043] Prepare raw mat...

Embodiment 2

[0055] according to figure 1 As shown, this embodiment proposes a low-emission breeding sewage resource and manure enzymatic microaerobic composting method for large-scale pig farms, including the following steps:

[0056] Step 1: Solid-liquid separation

[0057] Directly transport fresh pig manure and pig urine and feces water from the pigsty, use a solid-liquid separator to separate the solid and liquid from the fresh pig manure so that it does not contain urine, and control the water content of the pig manure at 20%-40% to obtain dried pig manure;

[0058] Step 2: Build the fermentation tank

[0059] Choose a flat open space, dig and build two fermentation tanks, control the internal volume of each fermentation tank to be able to absorb 20-25 days of fresh pig manure or pig urine and feces, and build a greenhouse on the fermentation tank, covering the greenhouse with 3 layer insulation film;

[0060] Step 3: Prepare the Fecal Fermentation Agent

[0061] Prepare raw mat...

Embodiment 3

[0073] according to figure 1 As shown, this embodiment proposes a low-emission breeding sewage resource and manure enzymatic microaerobic composting method for large-scale pig farms, including the following steps:

[0074] Step 1: Solid-liquid separation

[0075] Directly transport fresh pig manure and pig urine and feces water from the pigsty, use a solid-liquid separator to separate the solid and liquid from the fresh pig manure so that it does not contain urine, and control the water content of the pig manure at 20%-40% to obtain dried pig manure;

[0076] Step 2: Build the fermentation tank

[0077] Choose a flat open space, dig and build two fermentation tanks, control the internal volume of each fermentation tank to be able to absorb 20-25 days of fresh pig manure or pig urine and feces, and build a greenhouse on the fermentation tank, covering the greenhouse with 3 layer insulation film;

[0078] Step 3: Prepare the Fecal Fermentation Agent

[0079] Prepare raw mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com