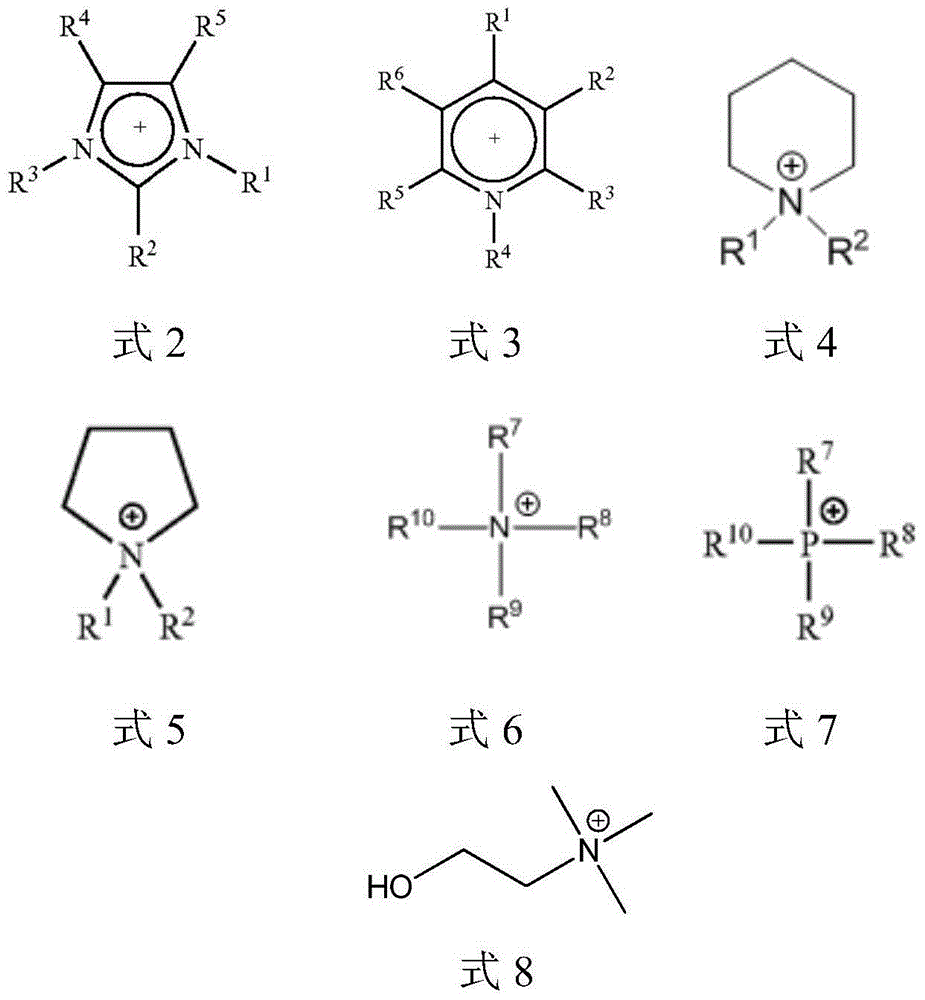

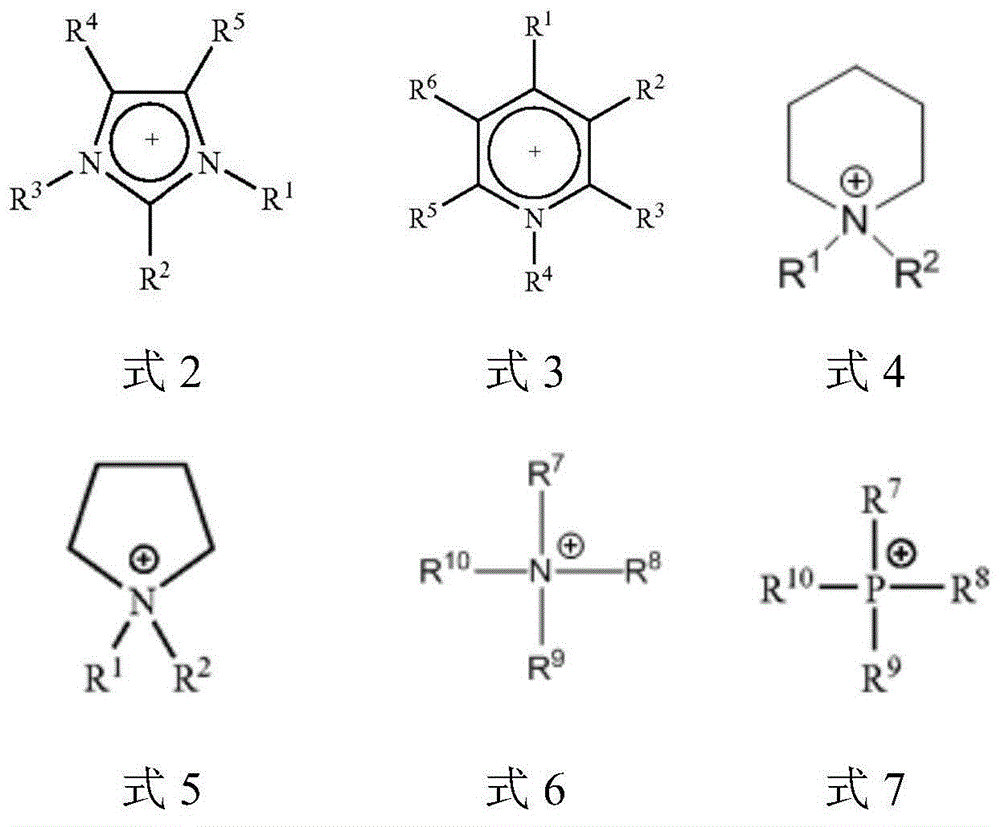

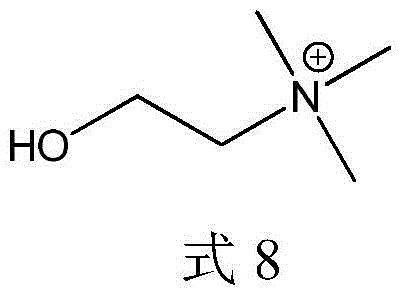

New method for dissolving lignin by ionic liquid containing sulfonic acid anion radicals

A sulfonic acid anion, ionic liquid technology, applied in the field of agricultural and forestry biomass resource utilization and treatment, can solve the problems of difficult disposal of waste liquid, high requirements for experimental containers, harsh conditions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Alkali lignin at 100℃ in ionic liquid [Ch][Me 2 NC 4 SO 3 ] Dissolution in

[0034] a), alkali lignin dissolved in ionic liquid: accurately weigh 1g of ionic liquid [Ch][Me] containing sulfonic acid anion group 2 NC 4 SO 3 ] in a 5ml sample bottle, heated to 100°C, then added 5mg of alkali lignin to the ionic liquid, and stirred at a speed of 300rpm until the alkali lignin was completely dissolved, and whether the dissolution was complete was observed with an optical microscope. After the alkali lignin is completely dissolved, add 5 mg of alkali lignin again until the maximum solubility is reached. Finally, at 100℃, alkali lignin in ionic liquid [Ch][Me 2 NC 4 SO 3 ] The maximum solubility in 265mg / g.

[0035] b), recycling of ionic liquids: [Ch][Me] containing alkali lignin 2 NC 4 SO 3 ] Add 3ml absolute ethanol in the ionic liquid, a large amount of alkali lignin solid particles are separated out, and alkali lignin-ionic liquid [Ch][Me 2 NC 4 SO 3 ]- Th...

Embodiment 2

[0037] Alkali lignin at 100℃ in ionic liquid [Et 4 N][Me 2 NC 4 SO 3 ] Dissolution in

[0038] a), alkali lignin dissolved in ionic liquid: accurately weigh 1g ionic liquid containing sulfonic acid anion group [Et 4 N][Me 2 NC 4 SO 3 ] in a 5ml sample bottle, heated to 100°C, then added 5mg of alkali lignin to the ionic liquid, and stirred at a speed of 300rpm until the alkali lignin was completely dissolved, and whether the dissolution was complete was observed with an optical microscope. After the alkali lignin is completely dissolved, add 5 mg of alkali lignin again until the maximum solubility is reached. Finally, at 100°C, alkali lignin in ionic liquid [Et 4 N][Me 2 NC 4 SO 3 ] The maximum solubility in 385mg / g.

[0039] b), recycling of ionic liquids: [Et 4 N][Me 2 NC 4 SO 3 ] Add 3ml absolute ethanol in ionic liquid, a large amount of alkali lignin solid particles are separated out, alkali lignin-ionic liquid [Et 4 N][Me 2 NC 4 SO 3 ]- The turbid sol...

Embodiment 3

[0041] Alkali lignin at 100℃ in ionic liquid [Et 4 N][i-PrNHC 3 SO 3 ] Dissolution in

[0042] a), alkali lignin is dissolved in the ionic liquid: accurately weigh 1g of the ionic liquid containing the sulfonic acid anion group [Et 4 N][i-PrNHC 3 SO 3 ] in a 5ml sample bottle, heated to 100°C, then added 5 mg of alkali lignin to the ionic liquid, stirred at a speed of 300 rpm until the alkali lignin was completely dissolved, and then added 5 mg of alkali lignin after the alkali lignin was completely dissolved, until the maximum solubility is reached. Finally, at 100°C, alkali lignin in ionic liquid [Et 4 N][i-PrNHC 3 SO 3 ] The maximum solubility in 345mg / g.

[0043] b), recycling of ionic liquids: [Et 4 N][i-PrNHC 3 SO 3 ] Add 3ml absolute ethanol in ionic liquid, a large amount of alkali lignin solid particles are separated out, alkali lignin-ionic liquid [Et 4 N][i-PrNHC 3 SO 3 ]- The turbid solution of ethanol is transferred to a centrifuge, and centrifuged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com