Modified titania and application thereof in spray-coating of outdoor PVC wood-plastic products

A technology for titanium dioxide and wood-plastic products, applied in coatings, chemical instruments and methods, and fibrous fillers, can solve problems such as reduced anti-ultraviolet effect, reduced surface gloss of products, and poor anti-ultraviolet performance of titanium dioxide. Improved UV and anti-aging properties, enhanced UV and anti-aging properties, and reduced sensory effects of topcoats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

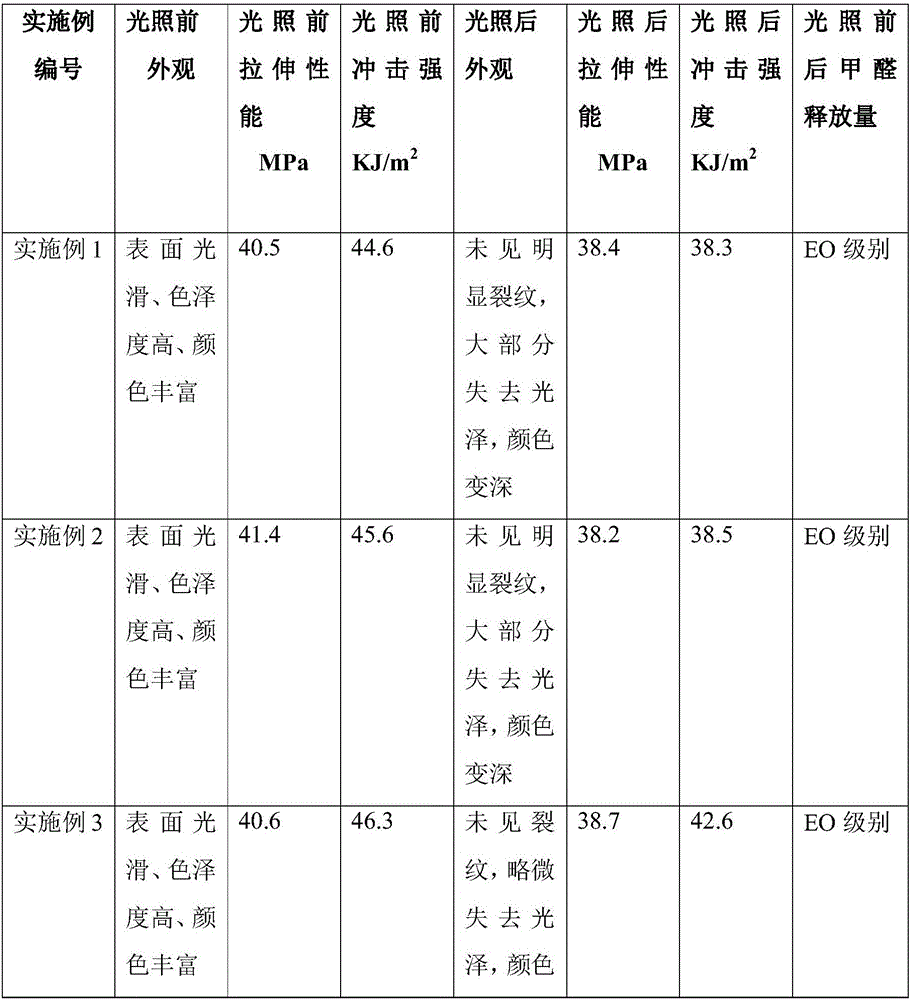

[0038] The formulation of the topcoat for wood-plastic products is as follows: Components by mass percentage: 85% polyacrylate base, 1% modified titanium dioxide, 5% stabilizer, 2% UV absorber, 7% carbon black and toner filler.

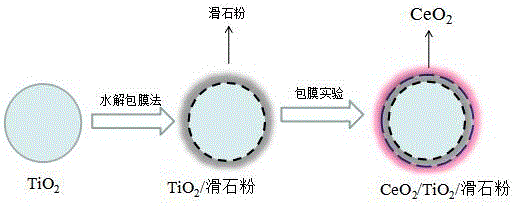

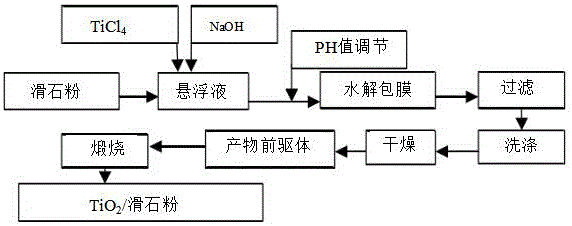

[0039] 1. TiO 2 / Preparation of talcum powder: the talcum powder, TiCl 4 And NaOH is added to water and blended to form a suspension, and distilled water is added to adjust the pH to 3. In parts by mass, talcum powder, TiCl 4 The mass sum of NaOH and NaOH accounts for 2 to 5%; TiCl in the suspension 4 Perform hydrolysis to obtain titanium dioxide, talc powder and coat it, and then filter, wash and dry to obtain TiO 2 / Talc powder precursor, and calcined at about 300 ° C to obtain the product TiO 2 / talcum powder.

[0040] 2. CeO 2 / TiO 2 / Preparation of talcum powder: the TiO prepared in step 1 2 / Talc powder and 0.25% sodium hexametaphosphate are mixed for dispersion treatment, the pH of the solution is adjusted to 10, the sand mill is melted ...

Embodiment 2

[0042] Embodiment 2: The preparation method is the same as in Embodiment 1, except that talcum powder and TiCl are prepared in the preparation of modified titanium dioxide 4 And NaOH, the molar ratio of cerium nitrate is 1:100:400:1.

Embodiment 3

[0043] Embodiment 3: The preparation method is the same as that of Embodiment 1, except that talcum powder and TiCl are prepared in the preparation of modified titanium dioxide 4 And NaOH, the molar ratio of cerium nitrate is 1:100:400:0.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com