Self-detection anticorrosive paint with nano-carriers, preparation method of paint and application

A technology of nano-carriers and anti-corrosion coatings, which is applied in anti-corrosion coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., and can solve problems such as failure of organic coating protection functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

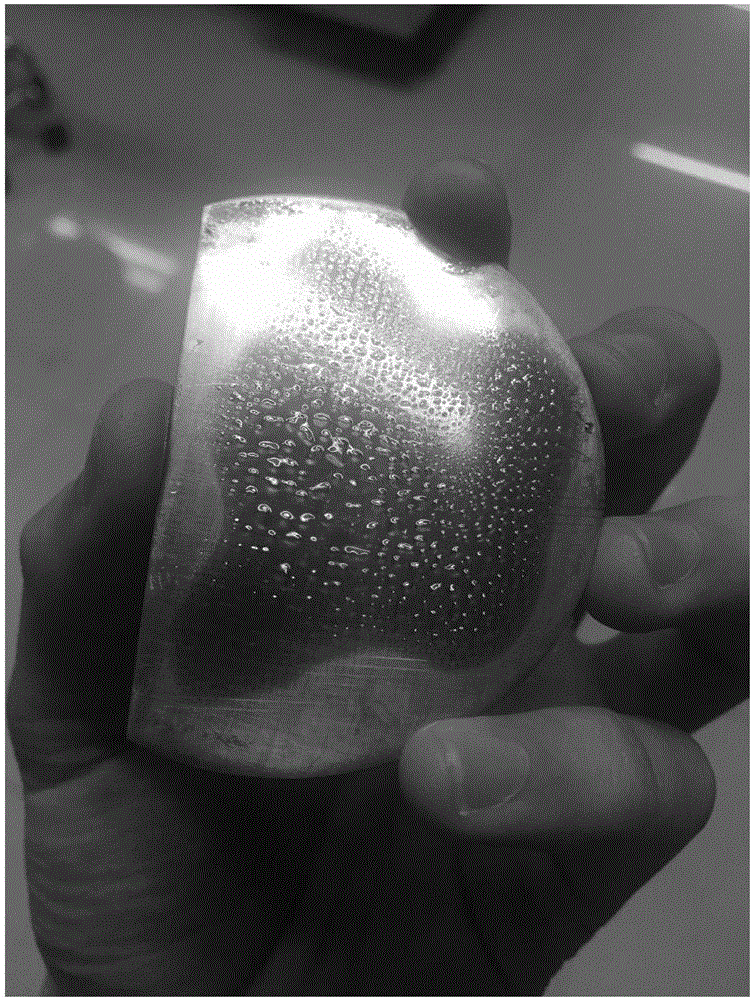

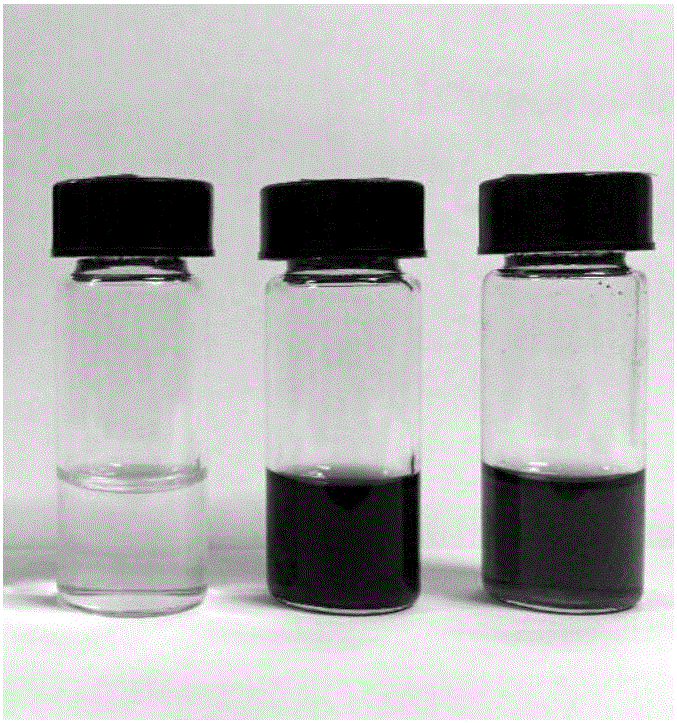

[0034] The preparation method and application of the self-detection anticorrosion coating containing nano-carriers of the present embodiment include the following steps:

[0035] Step 1, using the modified Hummer's method to prepare graphene oxide, and configuring it into a graphene oxide aqueous solution with a concentration of 2 mg / ml.

[0036] Step 2, mixing the graphene oxide aqueous solution and 1,10-phenanthroline at a mass ratio of 2:1 to obtain a first mixed solution.

[0037] Step 3, ultrasonically dispersing the first mixed solution in an ultrasonic instrument with an ultrasonic power of 300 W for 10 minutes to obtain a second mixed solution.

[0038] Step 4: Remove the unreacted solution in the second mixed solution by suction filtration to obtain a solid substance, and add water to the solid substance to form a third mixed solution of 2 mg / ml.

[0039] Step 5, mixing the third mixed solution with water-based polyurethane resin to obtain an anti-corrosion coating, ...

Embodiment 2

[0043] The preparation method and application of the self-detection anticorrosion coating containing nano-carriers of the present embodiment include the following steps:

[0044] Step 1, using the modified Hummer's method to prepare graphene oxide, and configuring it into a graphene oxide aqueous solution with a concentration of 2 mg / ml.

[0045] Step 2, mixing the graphene oxide aqueous solution with 1,10-phenanthroline pentaamino in a mass ratio of 2:1 to obtain a first mixed solution.

[0046] Step 3, ultrasonically dispersing the first mixed solution in an ultrasonic instrument with an ultrasonic power of 300 W for 10 minutes to obtain a second mixed solution.

[0047] Step 4: Remove the unreacted solution in the second mixed solution by suction filtration to obtain a solid substance, and add water to the solid substance to form a third mixed solution of 2 mg / ml.

[0048] Step 5, mixing the third mixed solution with water-based polyurethane resin to obtain an anti-corrosi...

Embodiment 3

[0052] The preparation method and application of the self-detection anticorrosion coating containing nano-carriers of the present embodiment include the following steps:

[0053] Step 1, use the improved Hummer's method to prepare graphene oxide, and configure it into a graphene oxide aqueous solution with a concentration of 2 mg / ml, and then add hydrazine hydrate not exceeding 0.3 times the mass of graphene to obtain graphene oxide after partial reduction graphene aqueous solution.

[0054] Step 2, mixing the partially reduced graphene aqueous solution with 1,10-phenanthroline at a mass ratio of 2:1 to obtain a first mixed solution.

[0055] Step 3, ultrasonically dispersing the first mixed solution in an ultrasonic instrument with an ultrasonic power of 300 W for 10 minutes to obtain a second mixed solution.

[0056] Step 4: Remove the unreacted solution in the second mixed solution by suction filtration to obtain a solid substance, and add water to the solid substance to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com