Coating material capable of restraining pellet binding inside COREX shaft furnace and preparation and application method thereof

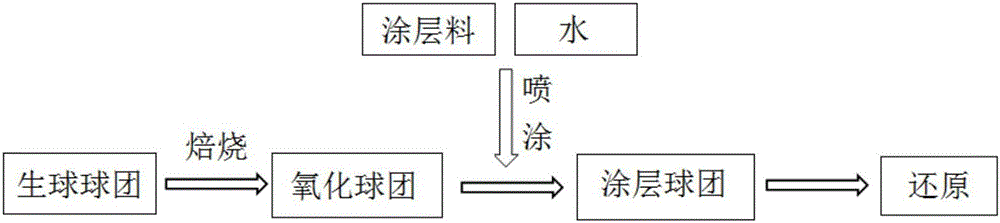

A technology of coating materials and pellets, which is applied in the field of smelting reduction ironmaking, can solve the problems of affecting the forward movement of the pre-reduction shaft furnace, reducing the efficiency of equipment use, and poor air permeability of the material column, so as to increase the burden of smelting, ensure the use effect, The effect of inhibiting adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

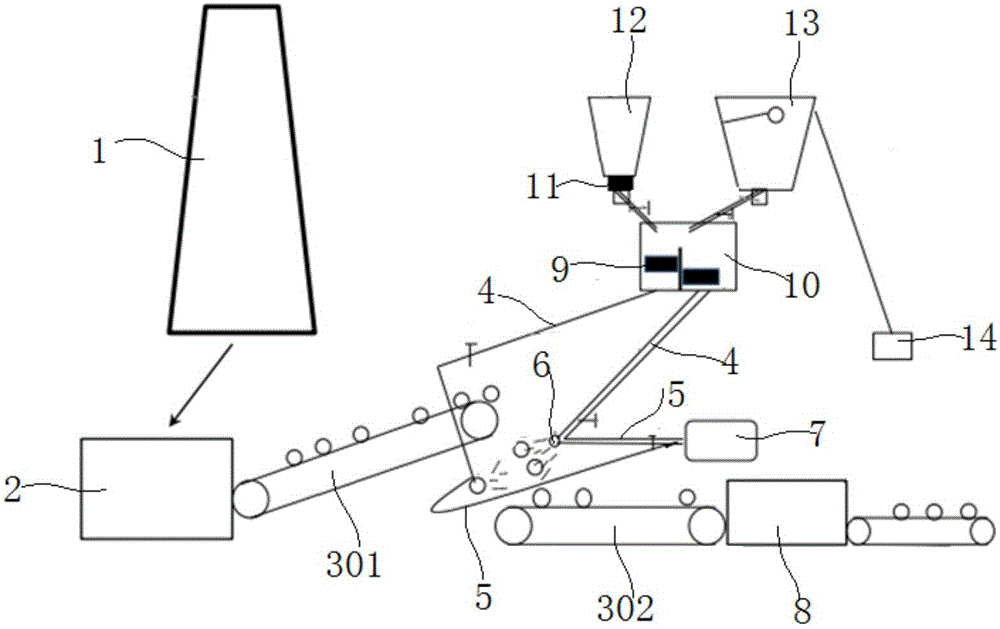

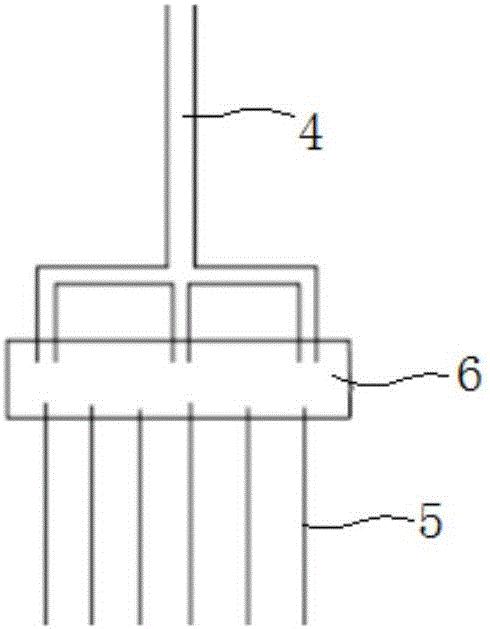

[0042] A kind of coating material that suppresses the pellet bonding in the COREX shaft furnace of the present embodiment, this coating material is made of lightly burned dolomite, Ca(OH) 2 , anthracite and water mixture, light burnt dolomite, Ca(OH) 2 The mass ratio of anthracite and anthracite is 6:1:2, and lightly burned dolomite, Ca(OH) 2 The sum of the mass of anthracite and anthracite accounts for 35% of the total mass of the mixed liquor. By selecting light burnt dolomite, Ca(OH) 2 and anthracite as a solid inhibitor, and optimize the mass ratio of each component and the mass concentration of the mixed solution, so as to ensure that the cohesion between pellets in the COREX shaft furnace can be effectively suppressed while still maintaining a high metal concentration. The rate of metallization can be reduced to prevent the reduction of metallization rate, and the coating material can be evenly coated on the surface of the pellets, and the combination of the coating ma...

Embodiment 2

[0066] A kind of coating material that suppresses the pellet bonding in the COREX shaft furnace of the present embodiment, this coating material is made of lightly burned dolomite, Ca(OH) 2 , anthracite and water mixture, light burnt dolomite, Ca(OH) 2 The mass ratio of anthracite and anthracite is 4:1:2, and lightly burned dolomite, Ca(OH) 2 The sum of the mass of anthracite and anthracite accounts for 30% of the total mass of the mixed liquor. The mass percent content of (MgO+CaO) in the lightly burned dolomite powder of this embodiment>70%, SiO 2 The mass percentage content of 2 The mass percentage of powders with a particle size of less than 75 μm in the powder is greater than 85%; the anthracite is a low melting point biomass additive containing only carbon and hydrogen, its melting point is less than 700 ° C, and the mass of the powder with a particle size of less than 105 μm in the anthracite Percent > 85%.

[0067] A method of using the coating material for inhibiti...

Embodiment 3

[0073] A kind of coating material that suppresses the pellet bonding in the COREX shaft furnace of the present embodiment, this coating material is made of lightly burned dolomite, Ca(OH) 2 , anthracite and water mixture, light burnt dolomite, Ca(OH) 2 The mass ratio of anthracite and anthracite is 5:1:2, and lightly burned dolomite, Ca(OH) 2 The sum of the mass of anthracite and anthracite accounts for 33% of the total mass of the mixed liquor. The mass percent content of (MgO+CaO) in the lightly burned dolomite powder of this embodiment>70%, SiO 2 The mass percentage content of 2 The mass percentage of powders with a particle size of less than 75 μm in the powder is greater than 85%; the anthracite is a low melting point biomass additive containing only carbon and hydrogen, its melting point is less than 700 ° C, and the mass of the powder with a particle size of less than 105 μm in the anthracite Percent > 85%.

[0074] A method of using the coating material for inhibiti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com