Preparation method of magnesium alloy surface coating and magnesium alloy

A technology of surface coating and magnesium alloy, applied in the field of magnesium alloy, can solve the problems of ceramic coating corrosion resistance and hardness to be improved, and achieve the effect of great research significance and good application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation method of the magnesium alloy surface coating of the present embodiment comprises the following processes:

[0056] A. The surface of the magnesium alloy substrate is ground and polished.

[0057] The material of the test piece selected in this embodiment is AZ31 magnesium alloy, wherein the content of magnesium is as high as 95%. The composition of the main elements of the specimen is shown in Table 1.

[0058] Table 1 Nominal composition (mass fraction)% of main elements of AZ31 magnesium alloy

[0059] Al

[0060] In this embodiment, the AZ31 magnesium alloy of 25mm × 25mm × 6.5mm is selected, and it is polished with 240, 400, 600, 800, 1200 mesh sandpaper respectively, and after polishing, the surface of the magnesium alloy is polished with a PG2A metallographic sample polishing machine Treatment, polishing until the surface of the magnesium alloy is mirror-like and free of scratches.

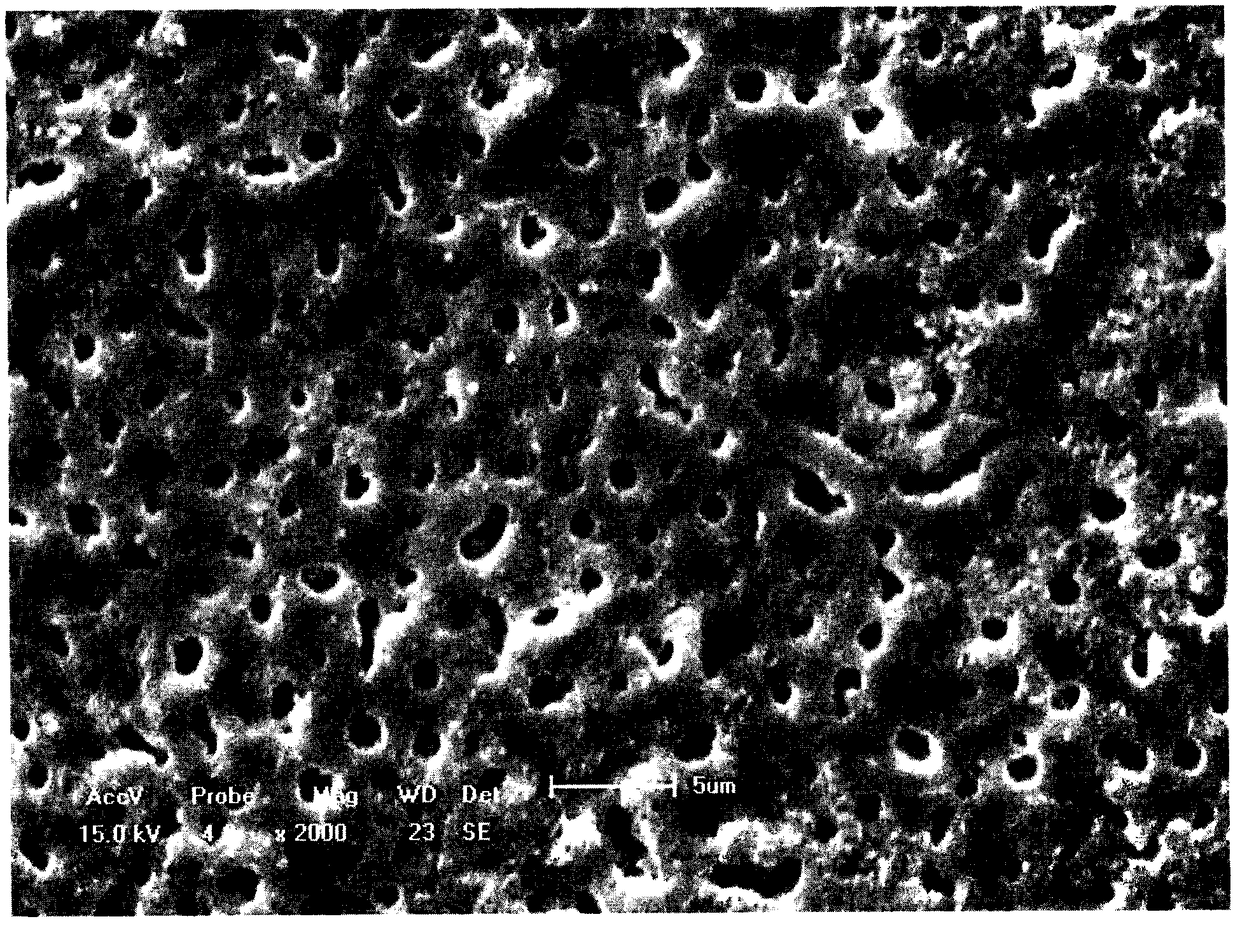

[0061] B. Perform micro-arc oxidation treatment on the...

Embodiment 2

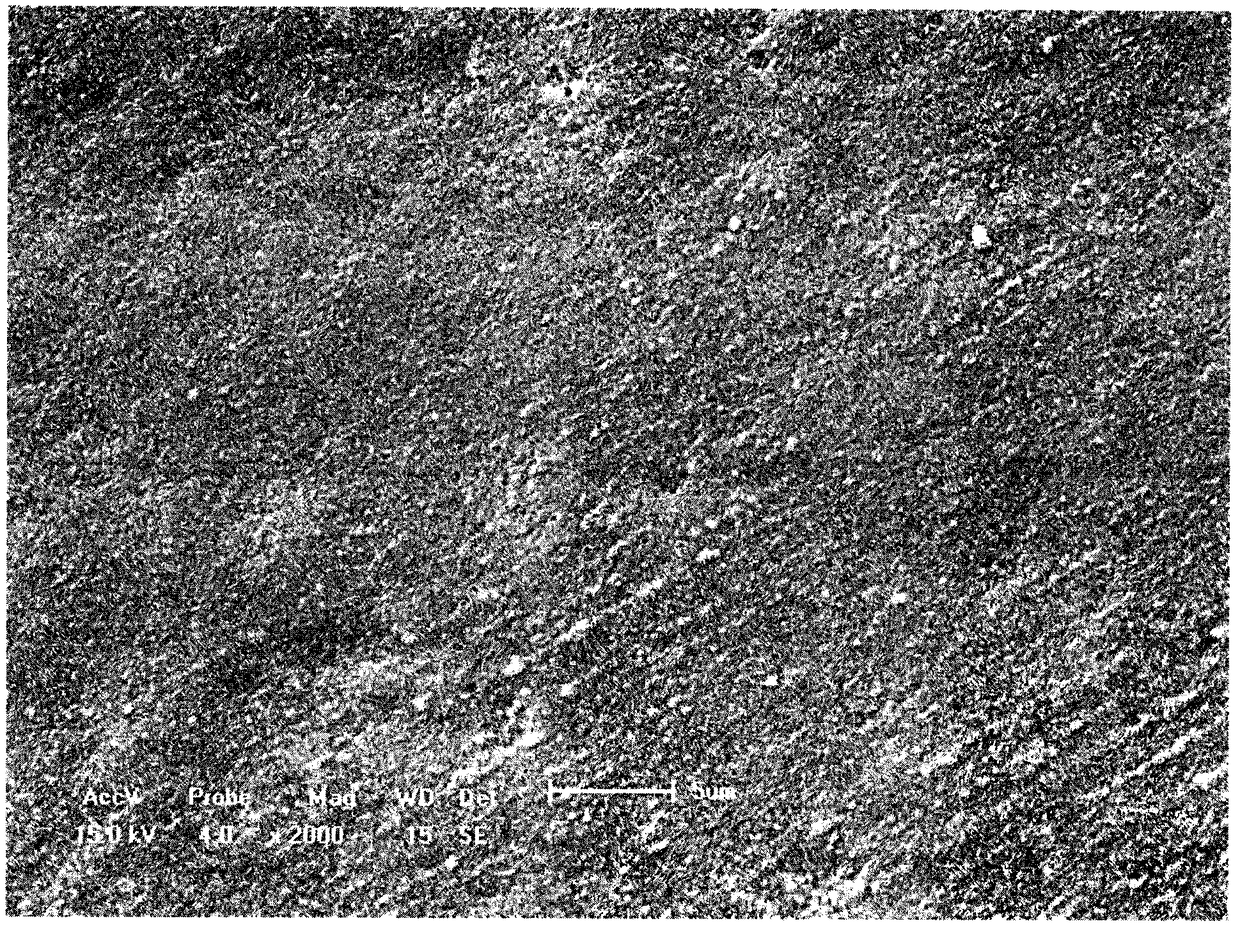

[0094] The main difference between this embodiment and embodiment one is the sol-gel process of step C, and the process of step C of this embodiment is as follows:

[0095] ①Weigh 9.8-9.9g of calcium nitrate and 1.75-1.8g of phosphorus pentoxide, and dissolve them in 25ml of absolute ethanol;

[0096] ② Slowly add the alcoholic solution of calcium nitrate to the alcoholic solution of phosphorus pentoxide, adjust the pH value to 7.1-7.3 with ammonia water, and magnetically stir for 20-40min, and finally stand at room temperature to obtain a sol solution.

[0097] ③Immerse the magnesium alloy with micro-arc oxidation coating in the sol solution for 20-40s, rotate or pull, bake at 70°C-80°C for 7-15min, and cool to room temperature;

[0098] ④Repeat step ③ multiple times according to different needs to form a semi-solidified gel film on the surface of the magnesium alloy;

[0099] ⑤ Carry out heat treatment on the magnesium alloy, place the magnesium alloy in the furnace, raise ...

Embodiment 3

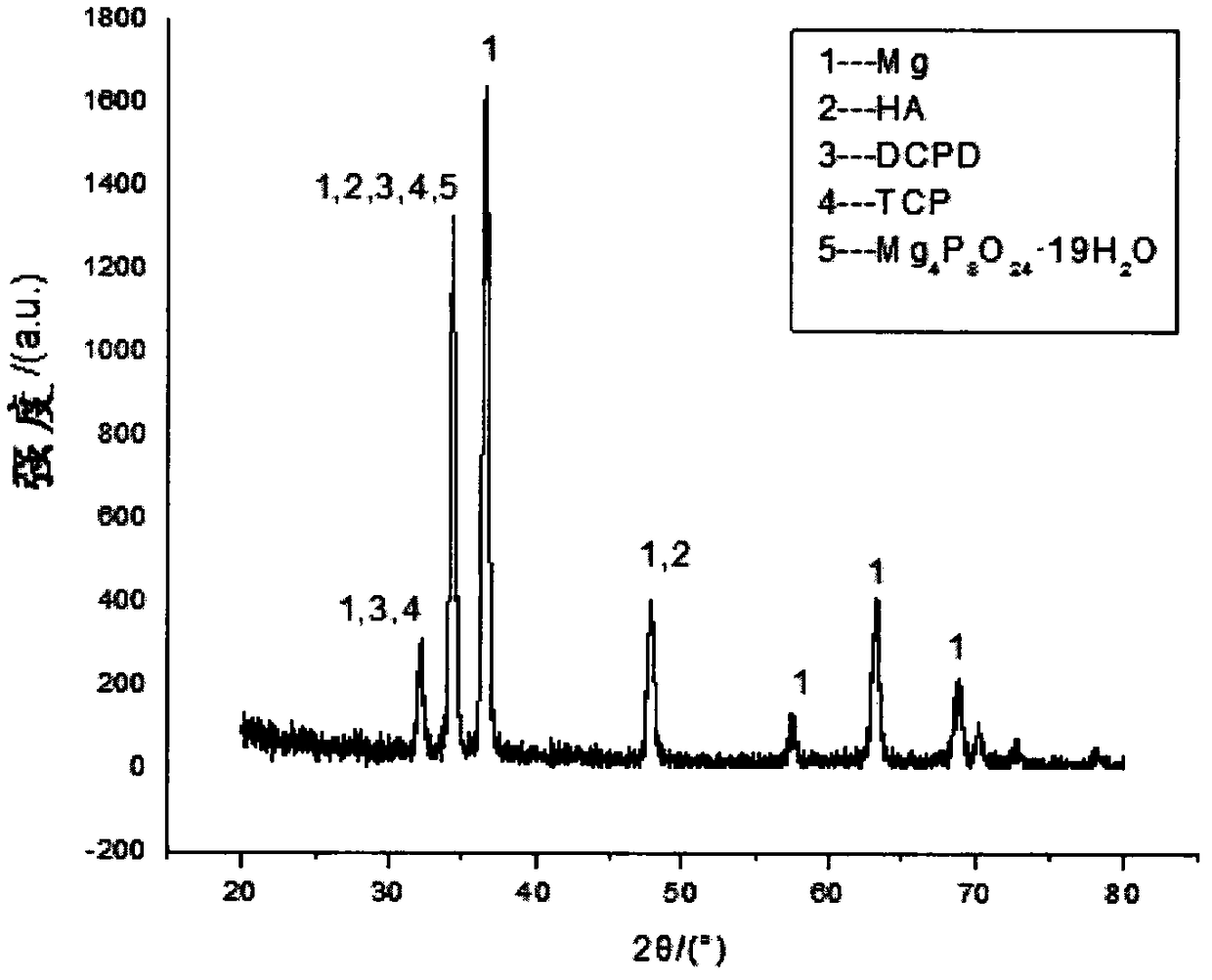

[0102] This example introduces a magnesium alloy prepared according to the method of the above example, its surface has a micro-arc oxidation coating made by a micro-arc oxidation process, and the surface of the micro-arc oxidation is covered with a coating made by a sol-gel process. sol-gel coating. The magnesium alloy is AZ31 magnesium alloy, the magnesium content of which is more than 95%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com