Pyroelectric composite material and preparation method and application in air purification

A composite material, pyroelectric technology, applied in the direction of climate change adaptation, electrostatic effect separation, chemical instruments and methods, etc., can solve the problem of difficult to apply air filter device, etc., to achieve the effect of excellent wear resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

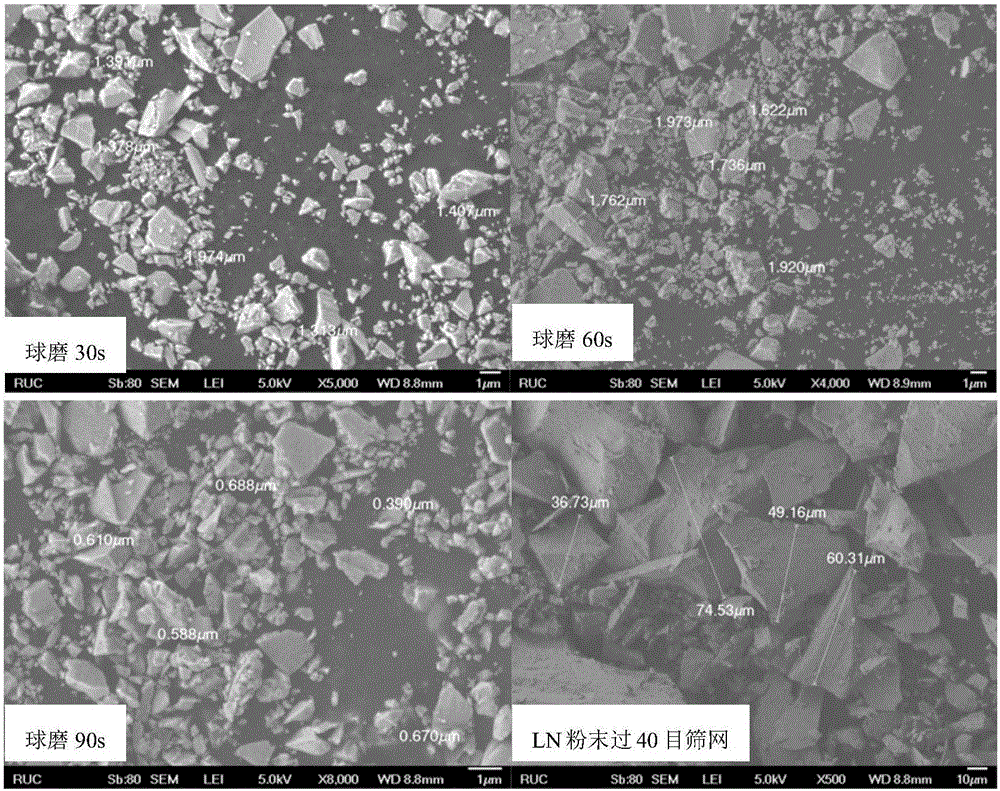

[0042] Embodiment 1, lithium niobate (LiNbO 3 ) Preparation of nanoparticles

[0043] LiNbO 3 The wafer is crushed and ground into powder, and then ball milled with a ball mill, and LiNbO with different particle sizes can be obtained by passing through screens of different meshes. 3 powder. Such as figure 1 shown. Because the large particles maintain the pyroelectric effect of the bulk crystal material, when the grain size is small to a certain scale, the pyroelectric effect is weakened or lost due to the instability of the polarization domain. When the particle size is larger than 180um, although the LN and LT particles maintain the same pyroelectric strength as the crystal material, their too large particle size is difficult to pass through the capillary and difficult to disperse during spinning, making the processing difficult to achieve . Therefore, the size range of the LN (LT) particles selected in the present invention is 100nm-180um.

Embodiment 2

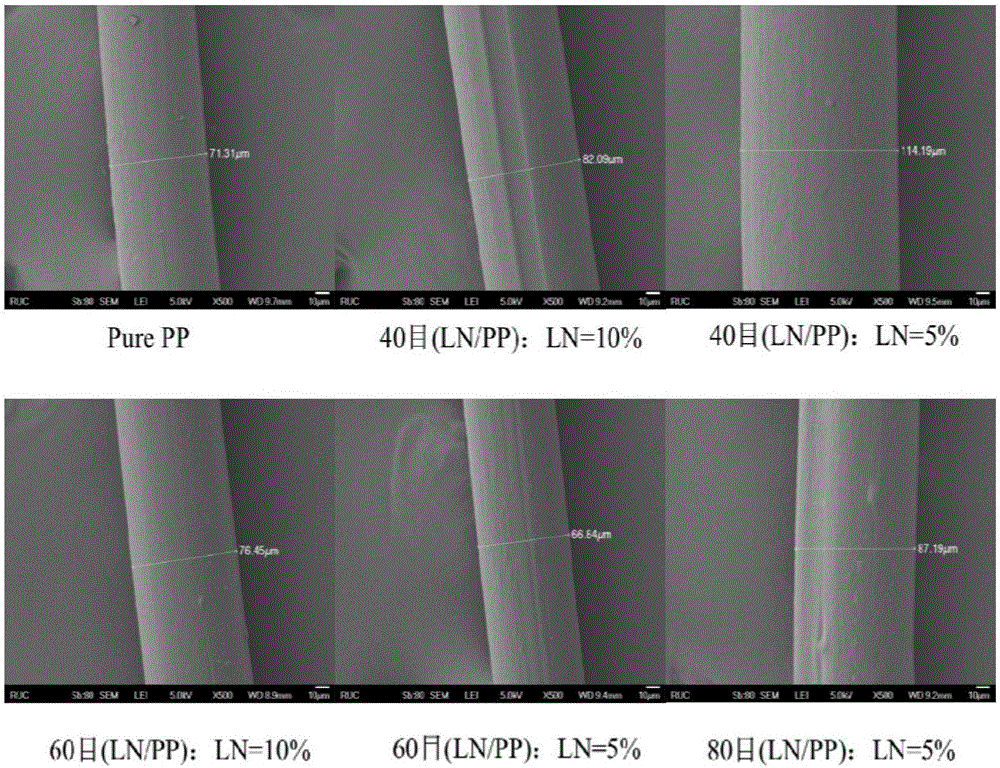

[0044] Embodiment 2, pyroelectric lithium niobate (LiNbO 3 ) Preparation of nanocomposite spinning

[0045] The above-prepared LN powder and PP (or PVC) pellets were melt-blended at 200°C, cooled naturally after completion, and then spun by RH-7 capillary rheometer to obtain samples. By adjusting the spinning parameters, fiber materials with good mechanical properties and pyroelectric effect can be prepared. Such as figure 2 It can be seen that after filling LN particles with the same particle size, the morphology of the fiber changes greatly with the spinning speed.

Embodiment 3

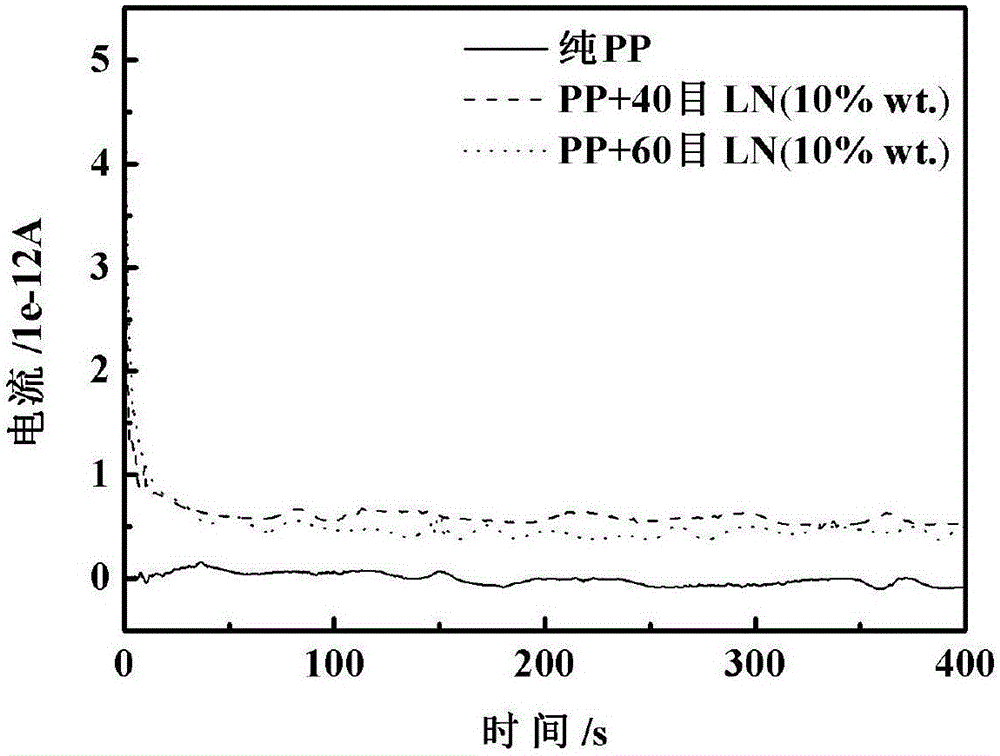

[0046] Embodiment 3, the electrical property measurement of PP / LN nanocomposite material

[0047] In order to prove the pyroelectric effect of the prepared PP / LN nanocomposite, the electrical effect of the fiber under the action of temperature (100°C) was measured by an electrochemical workstation. The single fiber prepared by spinning is connected to the positive and negative electrodes, and the current signal formed by the generated charge is measured under heating conditions. Such as image 3 As shown, after the electrodes are connected, a current signal is generated, and the charge is released instantaneously. Under the same conditions, the pure PP fibers without pyroelectric particles do not appear current signals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com