Method for preparing polytetrafluoroethylene superfine fiber and electrostatic spinning device thereof

A polytetrafluoroethylene and ultra-fine fiber technology, applied in the field of fiber manufacturing, can solve the problems of manufacturing PTFE fibers, difficult to use, and high melt viscosity, and achieve the effects of improving strength, enhancing stability, and avoiding unstable jet whipping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of manufacture method of the polytetrafluoroethylene superfine fiber that present embodiment provides, comprises the steps:

[0031] Dissolve polytetrafluoroethylene in the mixed solution of N-methylpyrrolidone and water, add graphene, and disperse evenly by ultrasonic to obtain a spinning fiber with a mass concentration of polytetrafluoroethylene of 60 g / L and a mass concentration of graphene of 10 g / L. liquid;

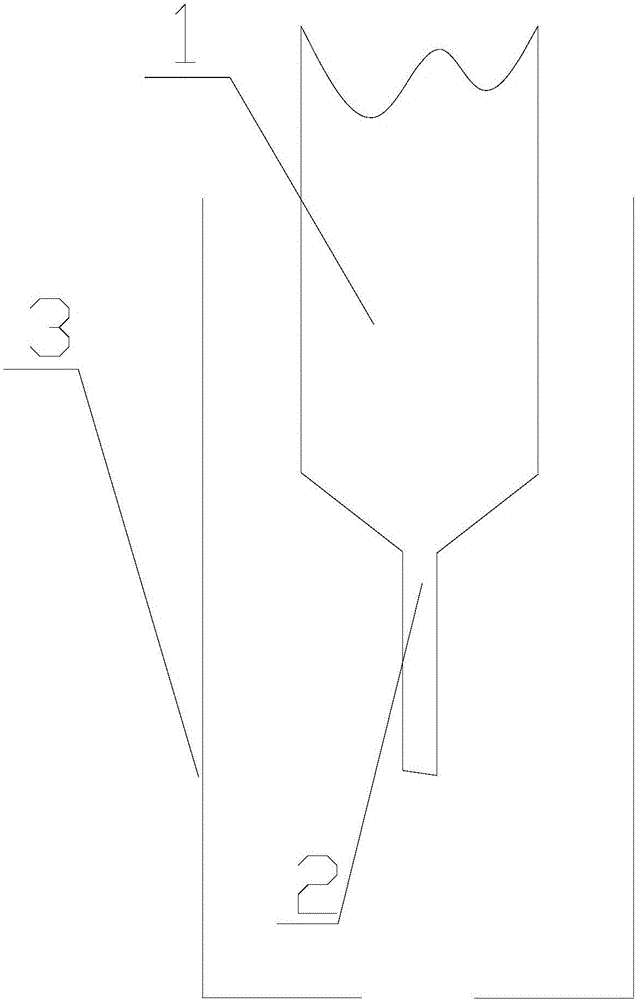

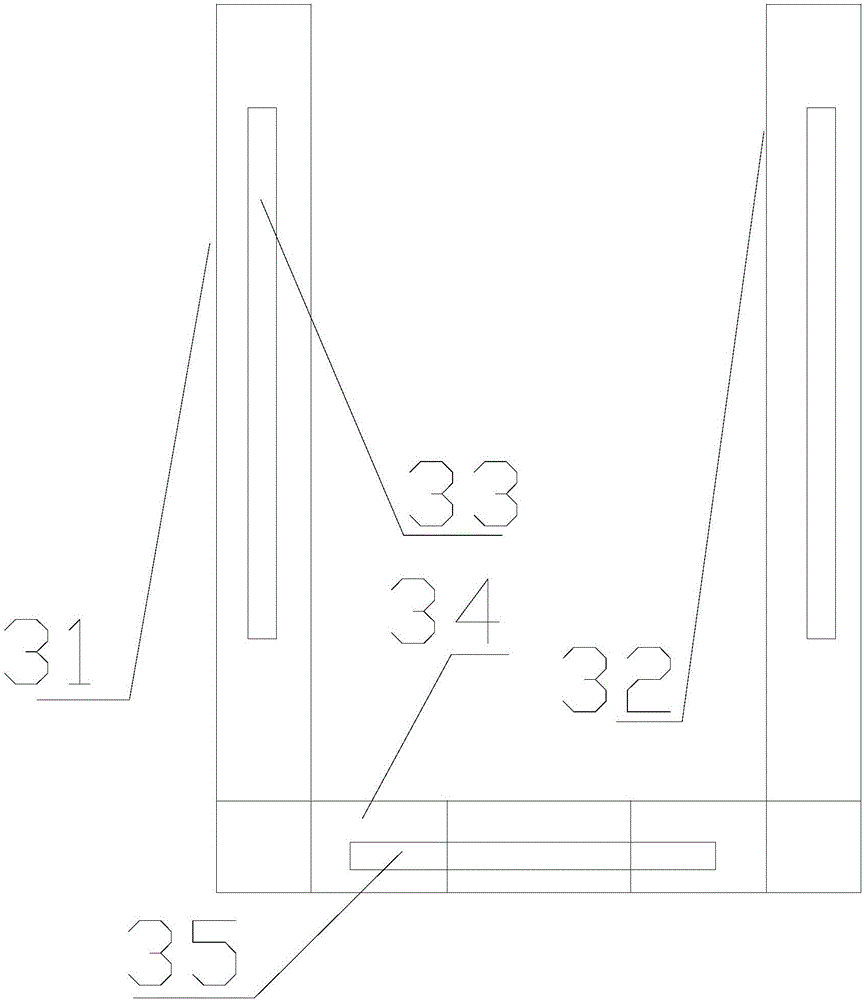

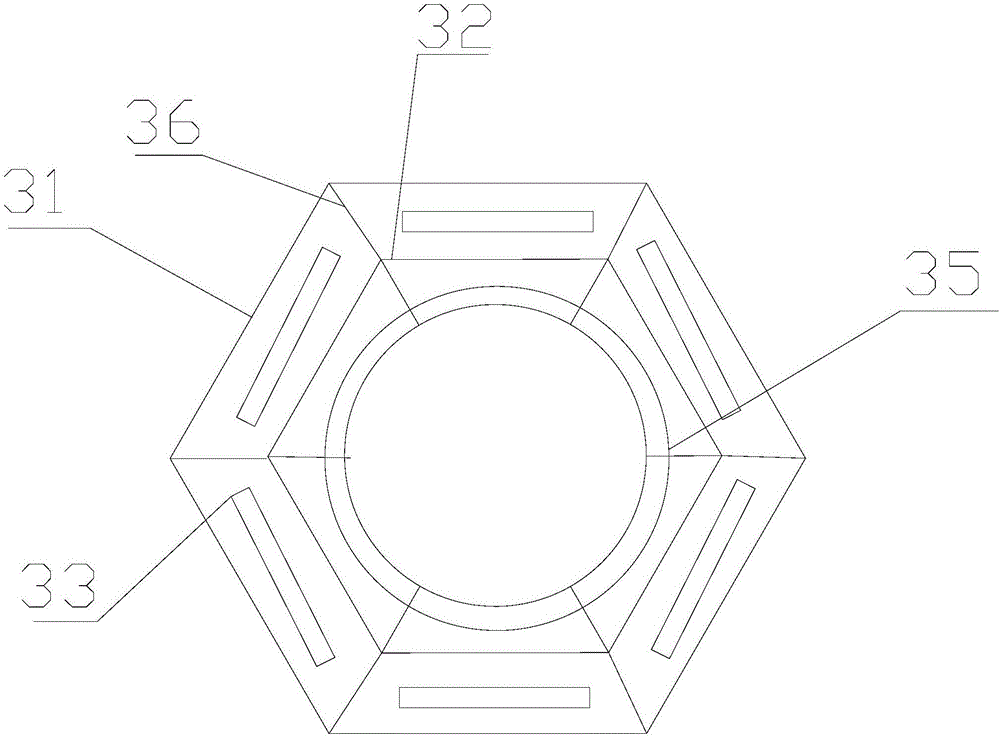

[0032] After vacuum defoaming the spinning solution, preheat to 50-95°C, according to Figure 1~3 Assemble the electrospinning device (because the remaining parts are conventional techniques in electrospinning, so not shown in the figure), the syringe 1 with the needle 2 is inserted into the ion wind supply device 3, wherein the ion wind supply device 3 includes: a housing, an ion emission source 35 and six blowers 33. The housing includes an outer shell 31 and an inner shell 32. There is a gap between the outer shell 31 and the inner shell 32, and the...

Embodiment 2

[0035] A kind of manufacture method of the polytetrafluoroethylene superfine fiber that present embodiment provides, comprises the steps:

[0036] Dissolving polytetrafluoroethylene in N-methylpyrrolidone, adding graphene and nano-titanium dioxide, and ultrasonically dispersing it uniformly to obtain a spinning solution with a mass concentration of polytetrafluoroethylene of 50 g / L and a mass concentration of graphene of 20 g / L;

[0037] After vacuum defoaming the spinning solution, preheat to 50-95°C, and assemble according to the electrospinning device in Example 1;

[0038] After the electrospinning device is assembled, the following technical parameters are set: the spinning speed is 5.0ml / h, the spinning voltage is 50kV, the needle moving speed is 3cm / min, the distance between the needle and the receiving device is 50cm, and the spinning humidity is 30 %, the spinning temperature is 35° C., the needle moving distance is 30 cm, and electrospinning is started for 3 hours to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com