Manufacturing process for eliminating white border lines of colorful marble tiles and colorful marble tiles

A manufacturing process, marble technology, applied in building construction, printing device, printing, etc., can solve the problems of limited pattern definition, unnatural visual contrast of white lines, and inability to express the fine texture and pattern level of natural marble surface, etc., to achieve Effects with rich texture changes and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

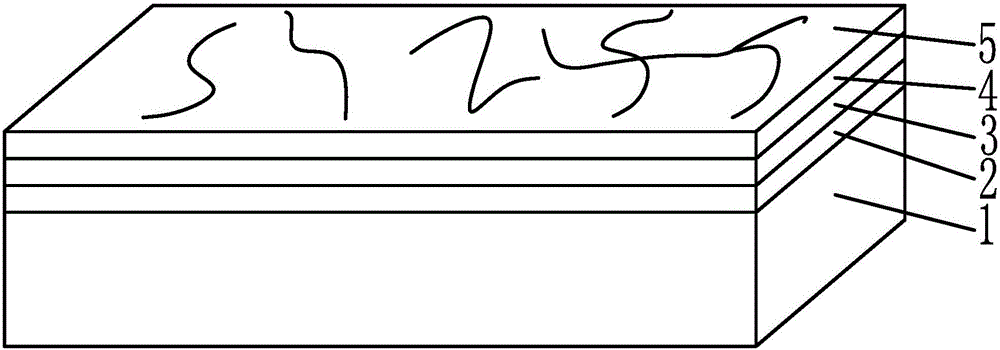

[0034] The product made in this embodiment is a whole body imitation marble full-glazed porcelain tile imitating gray wood grain sandstone.

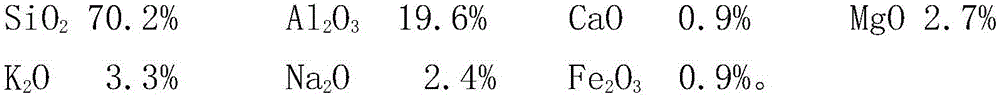

[0035] The chemical composition of the basic green body bottom layer is as follows by weight percentage:

[0036]

[0037] Green body water absorption <0.5%.

[0038] The chemical composition of basic green body fabric layer is specific as follows by weight percentage:

[0039]

[0040] Green body water absorption <0.5%.

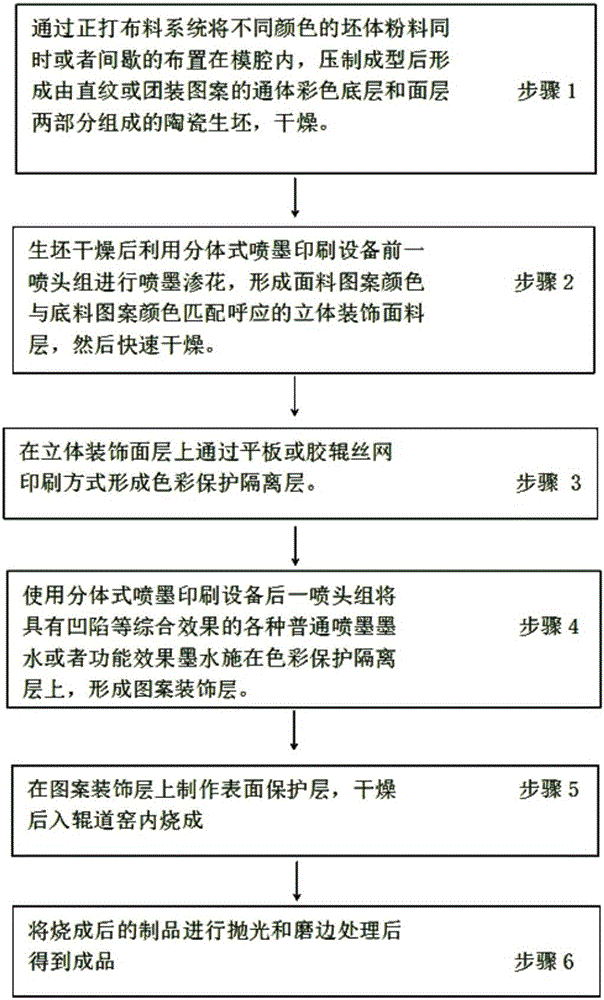

[0041] The manufacturing method of the whole body imitation gray wood grain marble fully glazed porcelain tile includes the following steps:

[0042] Process ⑴: Preparation of adobe

[0043] Through the dry-mixing automatic batching system, the powder material of the base body base layer and the dry-mixed color material are processed to obtain three different colors of color base materials and high-white fabrics, which enter the press twice and enter the fabric module according to the required color and patter...

Embodiment 2

[0053] The product made in this embodiment is a matte polished glazed porcelain tile imitating apricot-colored Oman beige stone.

[0054] The chemical composition of the basic green body bottom layer is as follows by weight percentage:

[0055]

[0056] Green body water absorption <0.5%.

[0057] The chemical composition of basic green body fabric layer is specific as follows by weight percentage:

[0058]

[0059] Green body water absorption <0.5%.

[0060] The manufacturing method of the whole body imitation Oman beige marble fully glazed porcelain tile comprises the following steps:

[0061] Process ⑴: Preparation of adobe

[0062] Through the dry-mixing automatic batching system, the powder material of the base body base layer and the dry-mixed color material are processed to obtain four different colors of color base materials and fabrics, which enter the press twice and enter the fabric module according to the required color and pattern effect into 904mm×904mm ...

Embodiment 3

[0071] The product made in this embodiment is a matte polished glazed porcelain tile imitating white Carrara stone.

[0072] The chemical composition of the basic green body bottom layer is as follows by weight percentage:

[0073]

[0074] Green body water absorption <0.5%.

[0075] The chemical composition of basic green body fabric layer is specific as follows by weight percentage:

[0076]

[0077] Green body water absorption <0.5%.

[0078] The whole body imitation white Carrara marble full cast glazed porcelain tile manufacturing method comprises the following steps:

[0079] Process ⑴: Preparation of adobe

[0080] Through the dry-mixing automatic batching system, the powder material of the base body base layer and the dry-mixed color material are processed to obtain two different colors of black and white base materials and a single high-white fabric, which enter the press twice into the cloth module according to the required color and pattern effect. The fab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com