Positive waste slurry recovery system and recovery method for lithium-ion battery

A lithium-ion battery and recycling system technology, applied in the lithium-ion battery cathode waste slurry recycling system and recycling field, can solve problems such as affecting battery quality, foreign matter agglomeration, mixed impurities, etc., to improve competitiveness, reduce pollution, ensure The effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

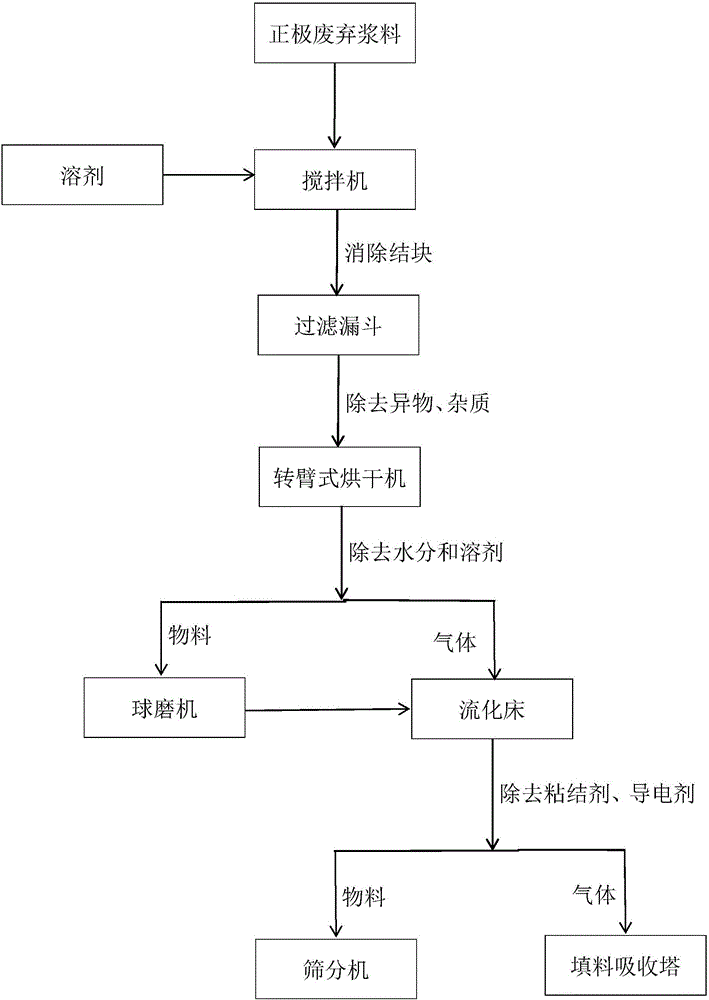

[0026] figure 1 The recovery process of the positive electrode slurry of the lithium ion battery in the present invention is shown. First, the positive electrode waste slurry is placed in a mixer, and the solvent (such as NMP) required for preparing the positive electrode slurry is added during normal production, and stirred. Until the agglomeration in the waste slurry disappears; the stirred slurry passes through the filter funnel to remove foreign matter and impurities; then enters the rotary arm dryer to further remove water and solvent; the slurry generated in the rotary arm dryer The powder is put into a ball mill for crushing; the crushed slurry powder enters the fluidized bed to further remove the binder and conductive agent, and at the same time, the harmful gas generated in the rotary arm dryer is also introduced into the flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com