A method for improving the smoking quality of reconstituted tobacco leaves by adopting comprehensive technology

A technology for reconstituted tobacco leaves, high quality, applied in the field of tobacco industry, can solve the problems of reducing the content of nicotine and protein macromolecules in reconstituted tobacco leaves, and achieve the effects of reducing green miscellaneous gas and rough taste, reducing the amount of tar, and reducing the spicy taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

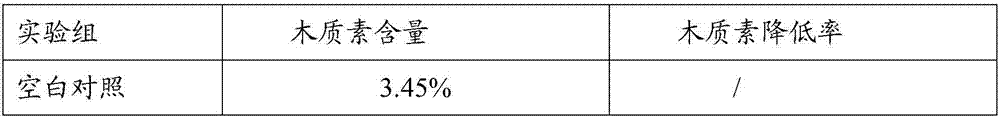

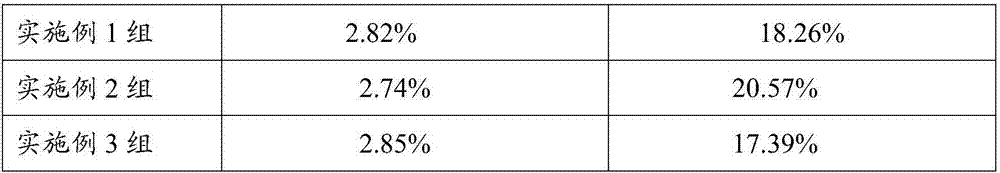

Embodiment 1

[0023] The invention provides a kind of reconstituted tobacco leaf which adopts comprehensive technology to improve the quality of smoking, comprising the following steps:

[0024] (1) Joint fermentation of ferulic acid esterase and white rot fungus lignin degrading enzyme laccase: in the extraction process of reconstituted tobacco leaves, ferulic esterase and white rot The fungal lignin-degrading enzyme laccase is added to the aqueous solution of reconstituted tobacco leaves and mixed evenly, the pH is adjusted to 5.0, and the enzymolysis is carried out at 50°C for 3 hours;

[0025] The ferulic acid esterase, food grade, enzyme activity 1000u / g, white rot fungus lignin degrading enzyme laccase, food grade, enzyme activity 1000u / g, the mass ratio is 1:1, respectively accounting for the mass ratio of reconstituted tobacco leaves 0.05%.

[0026] (2) Combined precipitation of tannic acid and tartaric acid: In the reconstituted tobacco leaf extract in the above step (1), add a mi...

Embodiment 2

[0033] The invention provides a kind of reconstituted tobacco leaf which adopts comprehensive technology to improve the quality of smoking, comprising the following steps:

[0034] (1) Joint fermentation of ferulic esterase and white rot fungus lignin degrading enzyme laccase: in the extraction process of reconstituted tobacco leaves, ferulic esterase and white rot The fungal lignin-degrading enzyme laccase is added to the reconstituted tobacco aqueous solution and mixed evenly, the pH is adjusted to 5.5, and the enzymolysis is carried out at 60°C for 4 hours;

[0035] Described ferulic acid esterase, food grade, enzyme activity 1000u / g, white rot fungus lignin degrading enzyme laccase, food grade, enzyme activity 500u / g, enzyme activity ratio is 1:1, and mass ratio is 1: 2, which account for 0.1% and 0.2% of the mass of reconstituted tobacco leaves respectively;

[0036](2) Combined precipitation of tannic acid and tartaric acid: In the reconstituted tobacco leaf extract in ...

Embodiment 3

[0044] The invention provides a kind of reconstituted tobacco leaf which adopts comprehensive technology to improve the quality of smoking, comprising the following steps:

[0045] (1) Joint fermentation of ferulic acid esterase and white rot fungus lignin-degrading enzyme laccase: in the extraction process of reconstituted tobacco leaves, ferulic esterase and white rot The fungal lignin-degrading enzyme laccase is added to the reconstituted tobacco aqueous solution and mixed evenly, the pH is adjusted to 6.0, and the enzymolysis is carried out at 65°C for 4 hours;

[0046] Described ferulic esterase, food grade, enzyme activity 500u / g, white rot fungus lignin degrading enzyme laccase, food grade, enzyme activity 500u / g, enzyme activity ratio is 1:1, and mass ratio is 1: 1, namely account for 0.1% and 0.1% of the mass of reconstituted tobacco leaves respectively;

[0047] (2) Combined precipitation of tannic acid and tartaric acid: In the reconstituted tobacco leaf extract of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com