Preparing method of green compound filter core material for indoor air purifier

A composite filter element and indoor air technology, applied in chemical instruments and methods, separation methods, applications, etc., to achieve the effects of long service life, excellent comprehensive performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

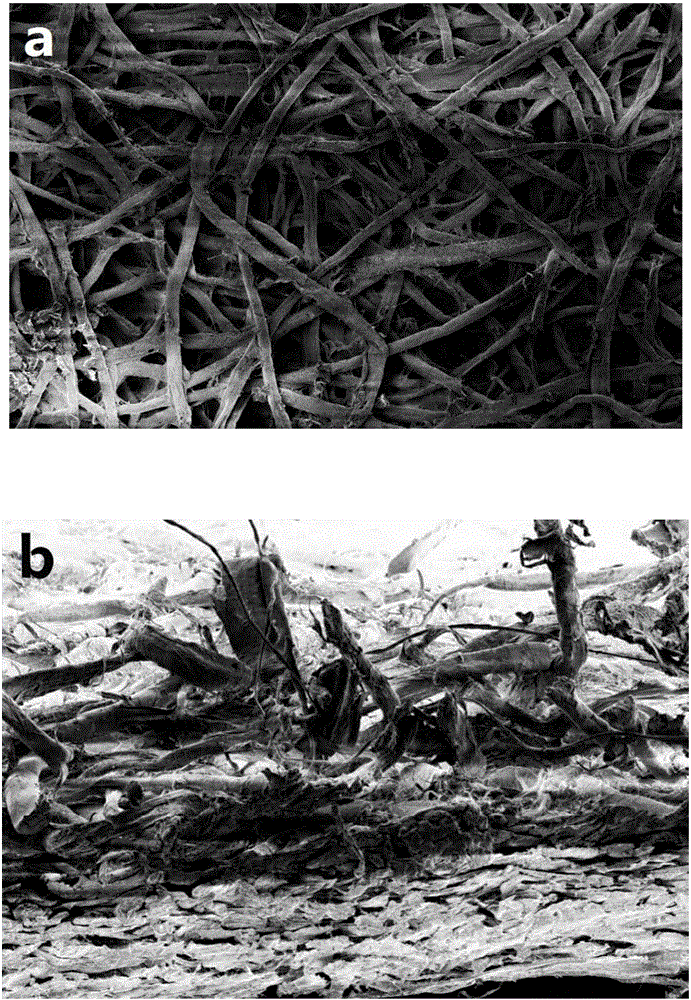

Image

Examples

Embodiment 1

[0020] 1) beating the rice straw pulp board and the mercerized pulp board to 30SR° and 34SR° respectively, and the beating concentration is 1%, so as to obtain the beaten rice straw pulp and mercerized pulp;

[0021] 2) the beating rice straw slurry obtained in step 1) is made into quantitatively 62g / m 2 The upper filter element material;

[0022] 3) The beating mercerized slurry obtained in step 1) is made into quantitatively 55g / m 2 The lower filter element material;

[0023] 4) adopting the interlayer wet compound process to obtain the upper layer filter element material and the lower layer filter element material above, wherein the mass ratio of the upper layer filter element material and the lower layer filter element material is 2:1, pressing and compounding to form the composite filter element material in a wet state;

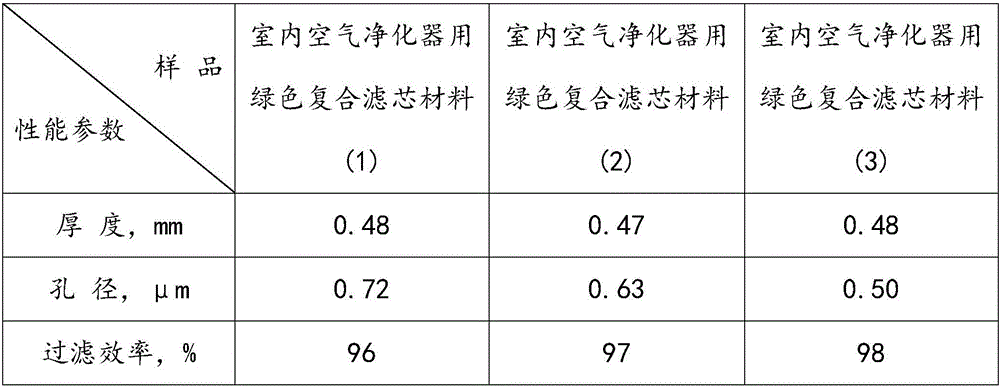

[0024] 5) Dry the wet composite filter element material obtained in step 4) at 70° C. and a vacuum of 0.8 MPa for 40 minutes to obtain a green composi...

Embodiment 2

[0026] 1) beating the straw pulp board and the mercerized pulp board to 32SR° and 36SR° respectively, and the beating concentration is 0.5%, to obtain the beaten wheat straw pulp and mercerized pulp;

[0027] 2) The beating wheat straw slurry obtained in step 1) is made into a quantitative value of 70g / m 2 The upper filter element material;

[0028] 3) The beating mercerized slurry obtained in step 1) is made into a quantitative ratio of 65g / m 2 The lower filter element material;

[0029] 4) adopt the interlayer wet compound process to obtain the upper layer filter element material and the lower layer filter element material above, wherein the mass ratio of the upper layer filter element material and the lower layer filter element material is 3:1, press and compound, and form the composite filter element material in a wet state;

[0030] 5) Dry the wet composite filter element material obtained in step 4) at 80° C. and a vacuum of 0.7 MPa for 50 minutes to obtain a green com...

Embodiment 3

[0032] 1) beat the bagasse pulp board and the mercerized pulp board to 36SR° and 30SR° respectively, and the beating concentration is 0.8%, to obtain the bagasse pulp and the mercerized pulp through beating;

[0033] 2) the bagasse slurry obtained in step 1) is made into quantitatively 60g / m through beating 2 The upper filter element material;

[0034] 3) The beating mercerized slurry obtained in step 1) is made into a quantitative ratio of 60g / m 2 The lower filter element material;

[0035] 4) adopting the interlayer wet compound process to obtain the upper layer filter element material and the lower layer filter element material above, wherein the mass ratio of the upper layer filter element material and the lower layer filter element material is 4:1, pressing and compounding to form the composite filter element material in a wet state;

[0036] 5) Dry the wet composite filter material at 90° C. and a vacuum of 0.6 MPa for 35 minutes to obtain a green composite filter mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com