Preparation of fe-n-c mesoporous carbon materials and their application in oxygen reduction reaction

A mesoporous carbon, fe-n-c technology, applied in the direction of physical/chemical process catalysts, structural parts, chemical instruments and methods, etc., can solve the problems of limiting fuel cell applications, limiting large-scale production, and expensive prices The effect of hydrogen oxide production, good resistance to methanol poisoning, and high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

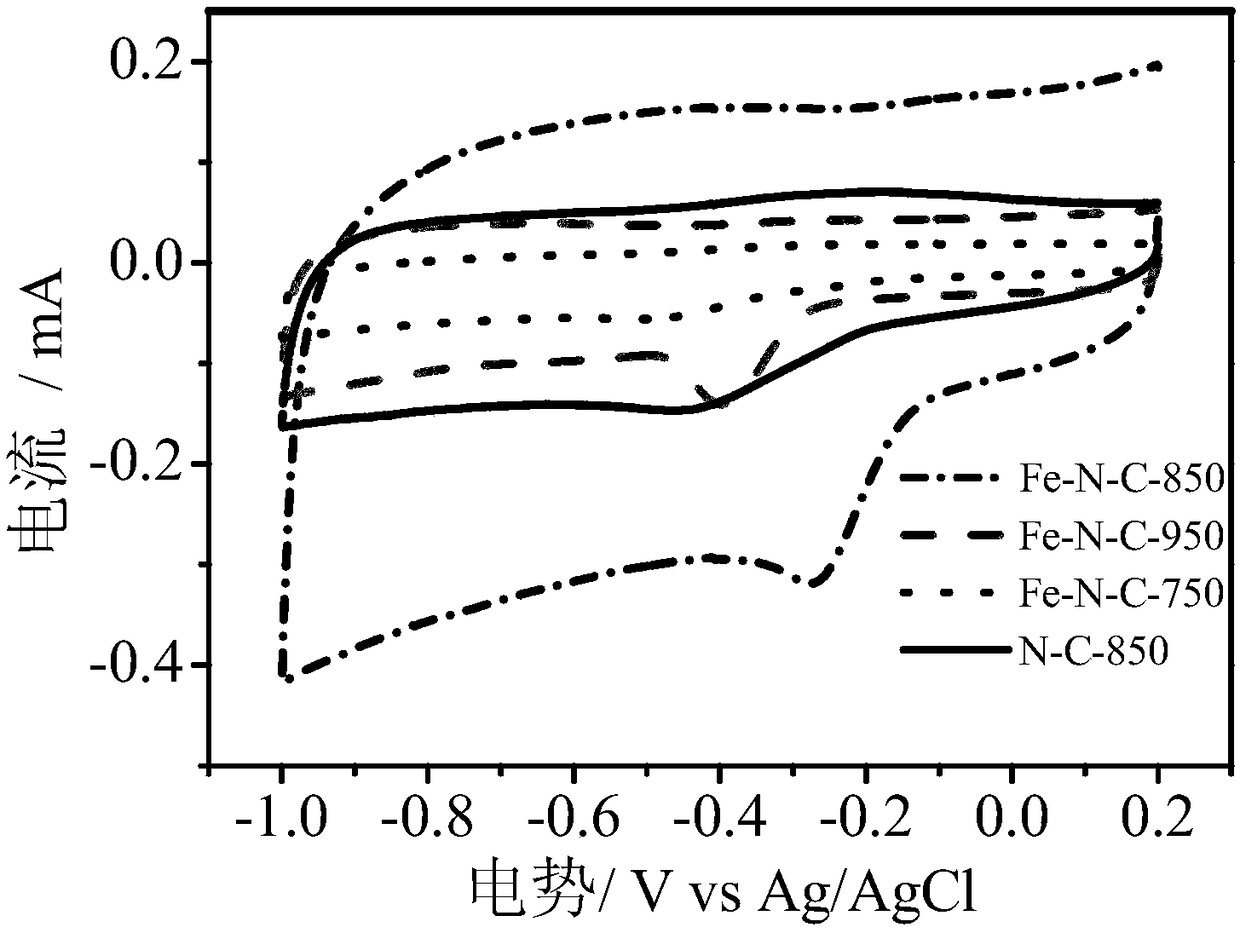

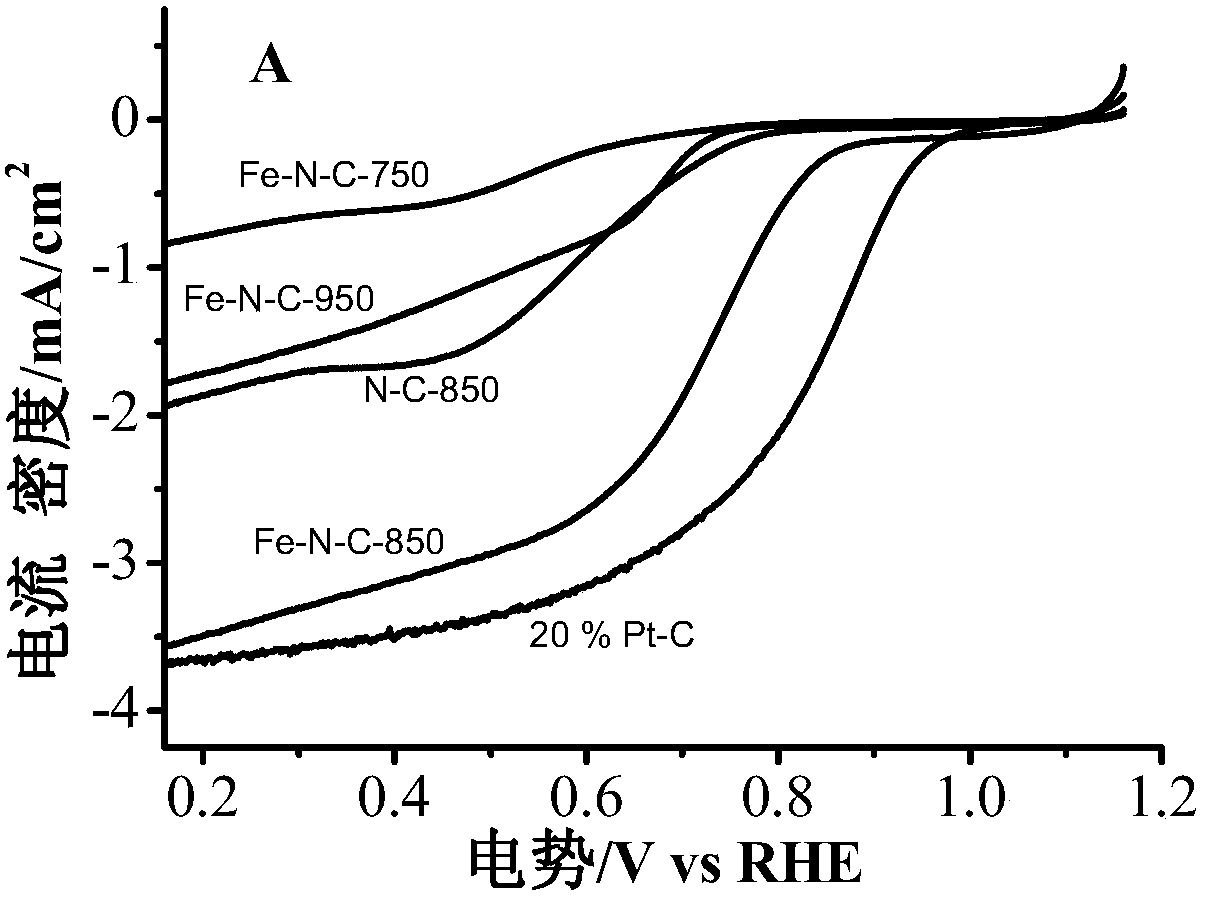

[0032] 1) Accurately weigh 10g Tris, 1g CA, and 1g FeCl 3 , grind and mix well to obtain a homogeneous yellow mixture. Then put the yellow mixture in a corundum boat (2*8*2cm) and put it in a blast drying oven (the temperature is set at 150°C, the maintenance time is 3 hours, and the air is not isolated), and a yellow-brown gel is obtained. thing.

[0033] 2) Heat the yellow jelly in a tube furnace at high temperature (heating rate 2.5°C / min, heating temperature 850°C) and maintain it for two hours to obtain a dark brown jelly, which is the initial iron-nitrogen-carbon composite Material. During the process of high temperature heating and temperature rise, the tube furnace kept feeding nitrogen.

[0034] 3) Put the composite material obtained in step 2) into 0.5mol / L sulfuric acid and treat it for 12 hours. During the treatment, stir it with a magnet at a stirring rate of 550rpm / min. Filtered and washed three times with double distilled water, dried for later use. Accordi...

Embodiment 2

[0037] The experimental procedure is the same as that of Example 1, except that the heating temperature in experimental procedure 2) is 750°C, and Fe-N-C-750 is prepared. The characterization method (SEM, TEM) is the same as in Example 1, and the electrochemical test method (CV, LSV) is also the same as in Example 1.

Embodiment 3

[0039] The experimental procedure is the same as that of Example 1, except that the heating temperature in experimental procedure 2) is 750°C, and Fe-N-C-950 is prepared. The characterization method (SEM, TEM) is the same as in Example 1, and the electrochemical test method (CV, LSV) is also the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com