Phosphorus-nickel-palladium co-doped carbon-based composite catalyst and preparation method and application thereof

A composite catalyst and co-doping technology, used in electrical components, battery electrodes, circuits, etc., can solve the problems of difficult large-scale commercial application, limited reserves, and expensive Pt catalysts, and achieve excellent electrocatalytic performance, The effect of low price and abundant raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Preparation of dimethylglyoxime nickel / palladium

[0083] (1) Weigh about 20.7 mg (±1 mg) of potassium tetrachloropalladate and 150 mg of nickel sulfate and dissolve them in 400 mL of tertiary water, and place them on a magnetic stirrer to fully stir to obtain a light green transparent solution.

[0084] (2) Weigh about 146 mg (±1 mg) of dimethylglyoxime and dissolve it in 12 mL of ethanol, ultrasonically dissolve it quickly, and add NaOH dropwise to adjust to pH=9-10.

[0085] (3) Under the stirring of a magnetic stirrer, the dimethylglyoxime solution was added dropwise to the solution, and a red precipitate was formed rapidly.

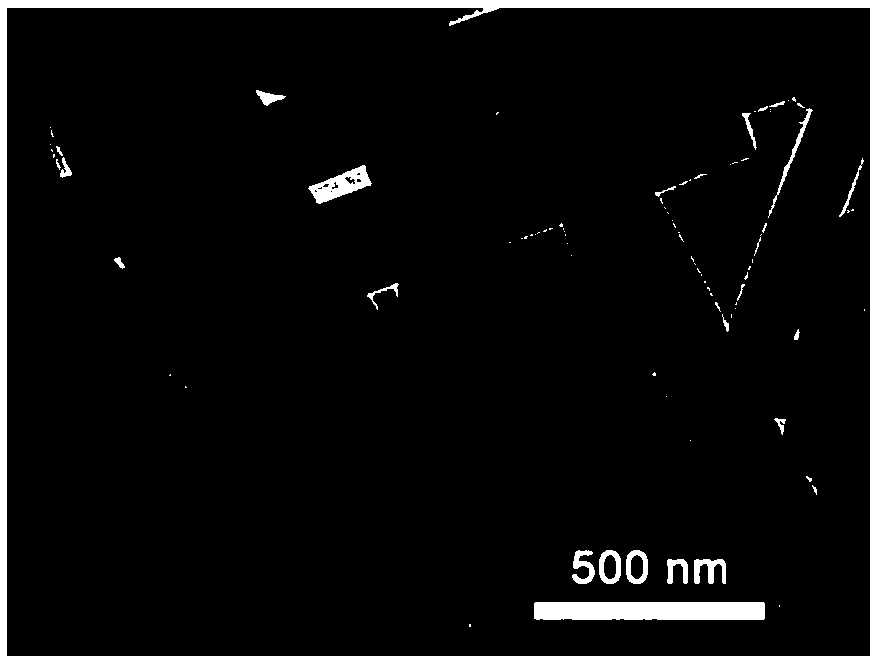

[0086] (4) The red precipitate was separated by suction filtration, washed three times with distilled water and ethanol respectively, and finally placed in an oven at 80°C for drying for 12 hours to obtain a red product, which was marked as dimethylglyoxime nickel / palladium such as figure 1 shown.

Embodiment 2

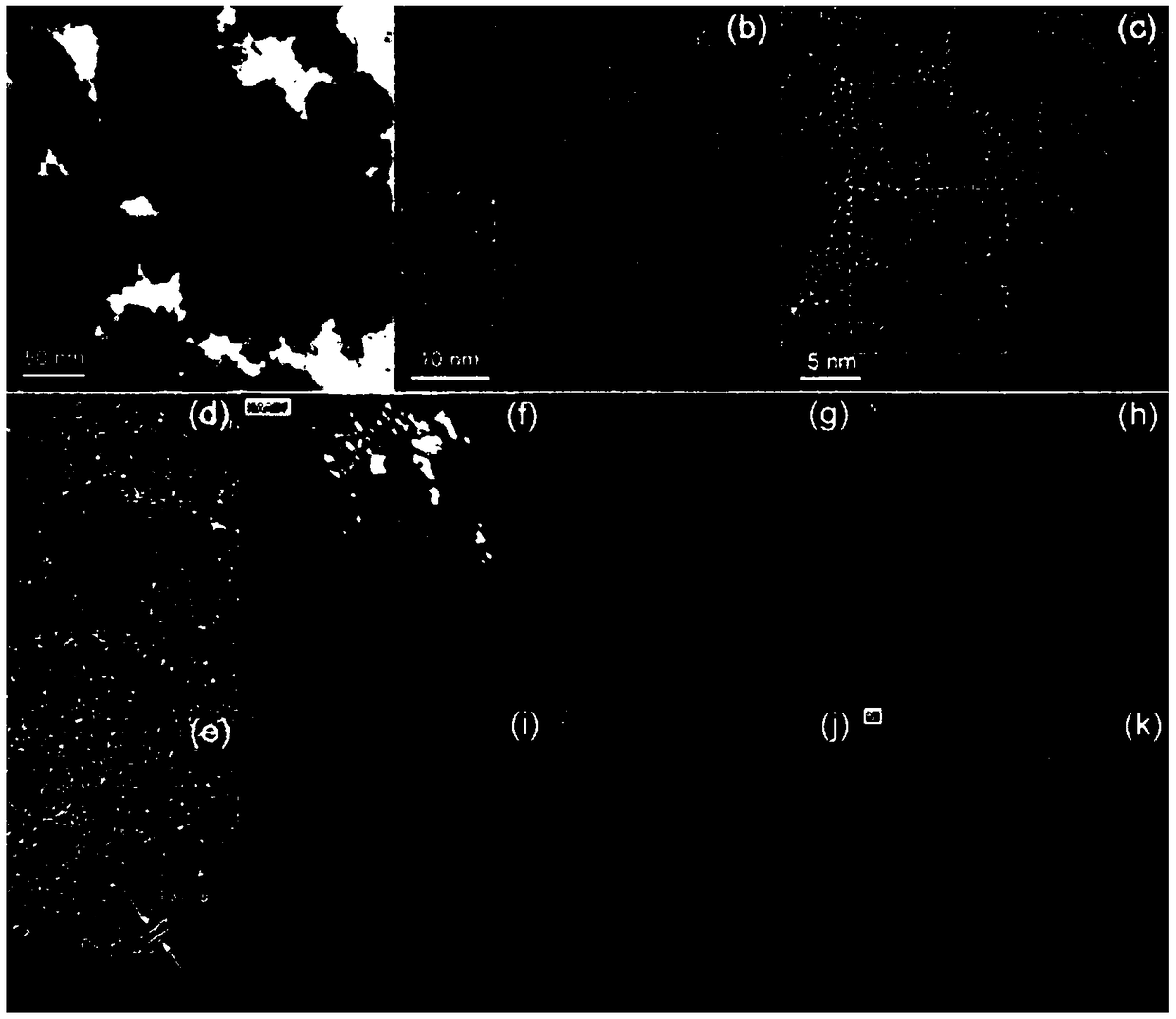

[0088] Using the dimethylglyoxime nickel / palladium obtained in Example 1 as a precursor, the catalyst of the present invention was prepared

Embodiment 3

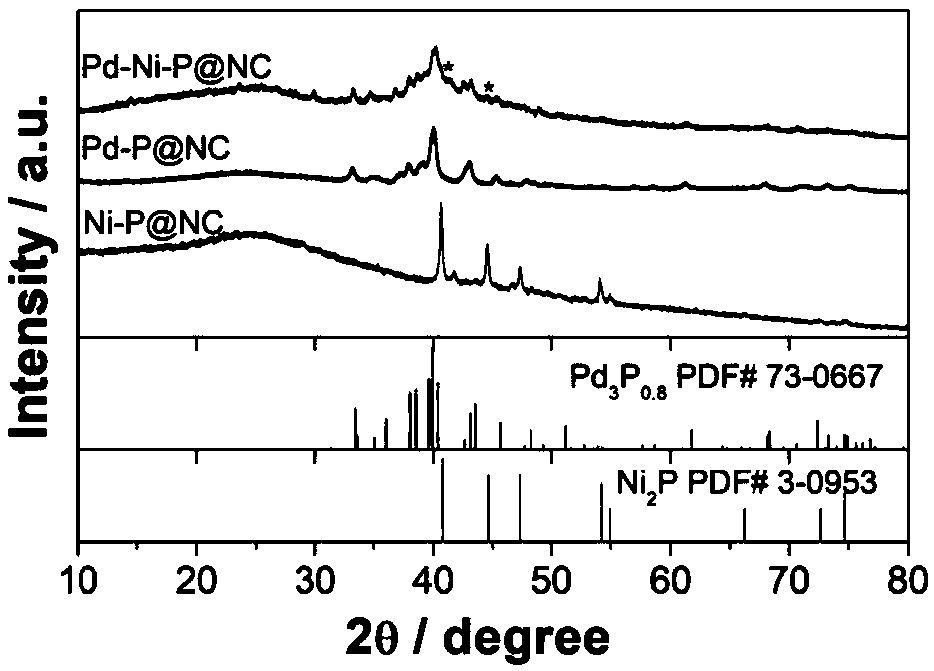

[0105] Comparing the catalytic performance of catalysts with different compositions

[0106] Disperse 2 mg of the catalysts obtained in Example 2, Comparative Example 1 and Comparative Example 2 into a mixed solution of 800 μL of water and 200 μL of isopropanol respectively, and ultrasonically disperse them uniformly to obtain 2 mg mL of -1 catalyst dispersion. When studying the catalytic performance, it is necessary to first drop 15 μL (dropwise three times, 5 μL each time) of the three catalysts obtained in this patent onto the RDE electrode (S=0.1256cm). 2 ), after being completely dried, 2 μL of 0.5% Nafion solution was finally added dropwise, and its ORR electrocatalytic performance was measured on a CHI 832B electrochemical workstation. For the above electrocatalytic performance tests, Ag / AgCl (3M NaCl) electrode was used as the reference electrode, Pt wire electrode (diameter 0.5mm) was used as the counter electrode, the scan rate was 10mV / s, and the electrolyte was 0.1M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com