Tin bronze alloy powder and preparation method thereof

A technology of alloy powder and tin bronze, which is applied in the field of tin bronze alloy powder and its preparation, can solve the problems of difficult shrinkage control, large bulk density, fast water cooling speed, etc., and achieves increased inventory turnover, low bulk density, loose bulk The effect of low packing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

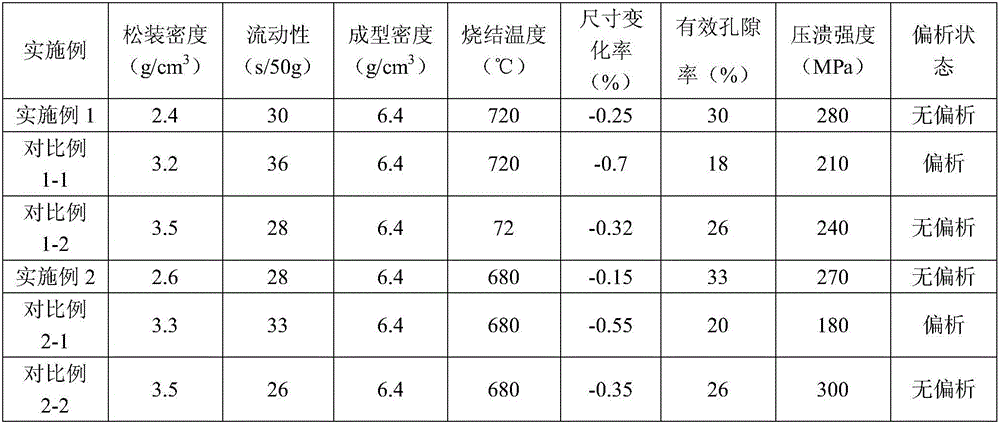

Examples

Embodiment 1

[0024] 1) Copper powder is prepared by water atomization method or electrolysis method, and the copper powder is roasted and crushed to obtain -200 mesh copper oxide powder, wherein the oxygen content is 16%;

[0025] 2) Prepare atomized copper-tin alloy powder by water atomization method, wherein the copper content is 50%, and the tin content is: 50%;

[0026] 3) adopt gas atomization method to prepare zinc powder;

[0027] 4) Put the copper oxide powder prepared in step 1), the atomized copper-tin alloy powder prepared in step 2), and the zinc powder prepared in step 3) in a double-cone mixer for 45 minutes to mix evenly, and prepare tin bronze powder The precursor, wherein the content of copper oxide powder is 12%, the content of copper-tin alloy powder is 84%, and the content of zinc powder is 4%;

[0028] 5) Place the tin bronze powder precursor prepared in step 4) in a reducing atmosphere for heat treatment, set the heat treatment temperature to 500°C, and heat treatmen...

Embodiment 2

[0035] 1) Prepare copper powder by water atomization method or electrolysis method, roast and crush the copper powder to obtain -200 mesh copper oxide powder, wherein the oxygen content is 18%;

[0036] 2) Atomized copper-tin alloy powder is prepared by water atomization method, wherein the copper content is 70%, and the tin content is: 30%;

[0037] 3) adopt gas atomization method to prepare zinc powder;

[0038] 4) Put the copper oxide powder prepared in step 1), the atomized copper-tin alloy powder prepared in step 2), and the zinc powder prepared in step 3) in a double-cone mixer for 45 minutes to mix evenly, and prepare tin bronze powder The precursor, wherein the content of copper oxide powder is 20%, the content of copper-tin alloy powder is 74%, and the content of zinc powder is 6%;

[0039] 5) Place the tin bronze powder precursor prepared in step 4) in a reducing atmosphere for heat treatment, set the heat treatment temperature to 600°C, and heat treatment time to 3...

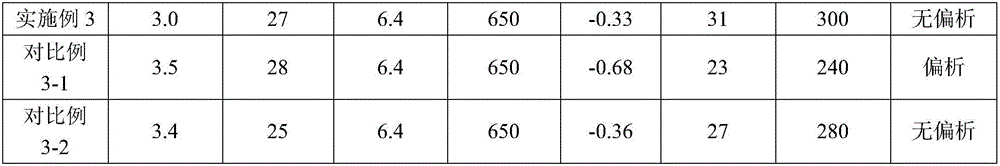

Embodiment 3

[0046]1) Copper powder is prepared by water atomization method or electrolysis method, and the copper powder is roasted and crushed to obtain -200 mesh copper oxide powder, wherein the oxygen content is 20%;

[0047] 2) Atomized copper-tin alloy powder is prepared by water atomization method, wherein the copper content is 90%, and the tin content is: 10%;

[0048] 3) adopt gas atomization method to prepare zinc powder;

[0049] 4) Put the copper oxide powder prepared in step 1), the atomized copper-tin alloy powder prepared in step 2), and the zinc powder prepared in step 3) in a double-cone mixer for 45 minutes to mix evenly, and prepare tin bronze powder The precursor, wherein the content of copper oxide powder is 25%, the content of copper-tin alloy powder is 60%, and the content of zinc powder is 15%;

[0050] 5) Place the tin bronze powder precursor prepared in step 4) in a reducing atmosphere for heat treatment, set the heat treatment temperature to 800°C, and heat trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com