Expanded graphite paper

A technology of expanded graphite and graphite paper, applied in the field of preparation of expanded graphite paper, can solve the problems of graphene yield less than 20%, low efficiency of electrochemical stripping, etc., to achieve improved stripping efficiency, obvious expansion effect, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] First, immerse the graphite paper in liquid nitrogen (-196°C), take it out after 1 minute, and then quickly immerse it in boiling (100°C) pure water, and use the rapid nitrogen evolution and water solidification to form graphite sheets Rapid expansion, after the expansion process is completed, it is taken out, washed with water, and dried to obtain the treated expanded graphite paper. The graphite paper was used as raw material (16.0 g) for electrochemical exfoliation, that is, in a 1 Mol / L sulfuric acid solution, a forward voltage of 3 V was applied to the graphite electrode, and the graphite was rapidly exfoliated into graphene. Finally, 14.2 g of graphene products can be obtained with a yield of 88.8%.

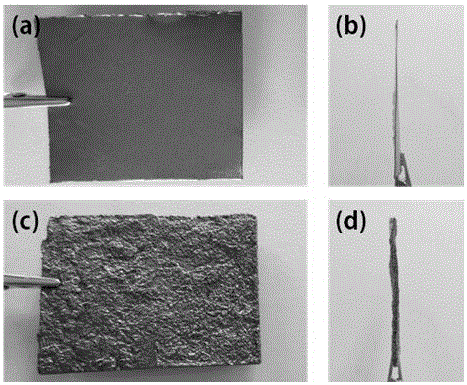

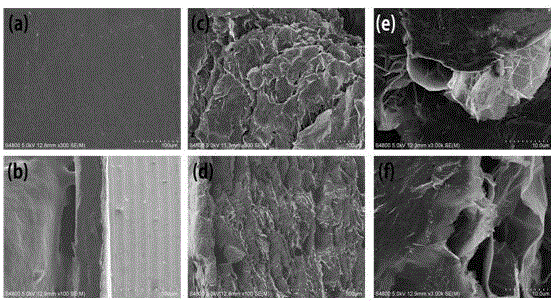

[0019] attached by figure 1 It can be seen that the expansion effect of the treated graphite paper in Example 1 is obvious. attached by figure 2 It can be seen that compared with the original graphite paper, the microscopic appearance of the expanded graphite pap...

Embodiment 2

[0021] First, immerse the graphite paper in liquid oxygen (-183°C), take it out after 1 minute, and then quickly immerse it in ethanol at room temperature (20°C), and use the rapid oxygen evolution and solidification of ethanol to make the graphite sheets rapidly Expansion, after the expansion process is completed, it is taken out, washed with water, and dried to obtain the treated expanded graphite paper. The graphite paper was used as the raw material (17.3 g) for exfoliation, that is, in a 1 Mol / L sulfuric acid solution, a forward voltage of 3 V was applied to the graphite electrode, and the graphite was rapidly exfoliated into graphene. Finally, 14.4 g of graphene products can be obtained with a yield of 83.2%.

Embodiment 3

[0023] First, immerse the graphite paper in liquid carbon dioxide (-37°C), take it out after 5 minutes, and then quickly immerse it in boiling (100°C) pure water, using the rapid precipitation of carbon dioxide and the solidification of water to form graphite sheets Rapid expansion, after the expansion process is completed, it is taken out, washed with water, and dried to obtain the treated expanded graphite paper. The graphite paper was used as the raw material (12.0g) for exfoliation, that is, in a 1 Mol / L sulfuric acid solution, a forward voltage of 3V was applied to the graphite electrode, and the graphite was rapidly exfoliated into graphene. Finally, 9.8 g of graphene products can be obtained with a yield of 81.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com