Method for constructing high-adhesion super-hydrophobic surfaces

A super-hydrophobic surface and high-adhesion technology, applied in the field of surface treatment of functional materials, can solve the problems of time-consuming and labor-consuming, cumbersome steps, expensive chemical raw materials, etc., and achieve high contact angle, cheap, simple and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

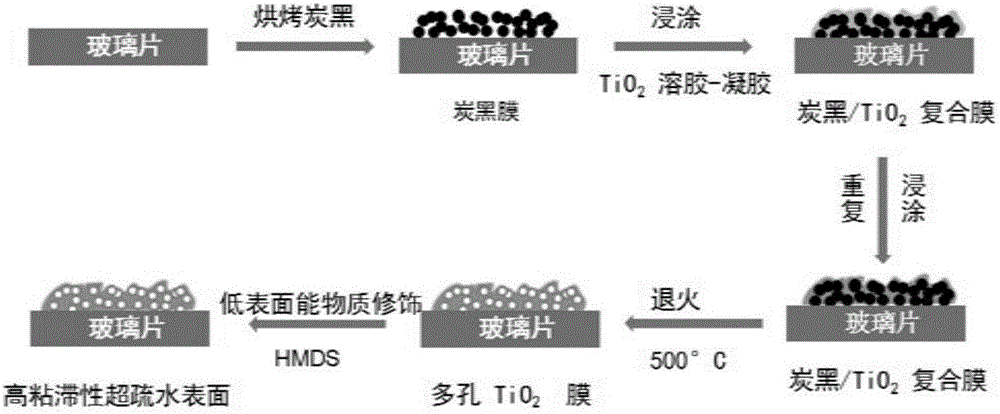

[0051] figure 1 Prepare the experimental flow chart of highly adhesive superhydrophobic surface for the present invention, concrete steps are as follows:

[0052] (1) Preparation of TiO 2 Sol-gel:

[0053] Take 50ml of absolute ethanol and place it in a beaker, and add 0.27ml of acetylacetone dropwise into it, and stir for 10min with a magnetic stirrer at a speed of 200rpm. Then, 0.85ml of TEOT was added dropwise to the mixture of absolute ethanol / acetylacetone, stirred with a magnetic stirrer for 1 hour, and left to stand to obtain a titanium dioxide sol-gel, which was aged for 4 days and then used for later use.

[0054] (2) Preparation of carbon black / titanium sol-gel composite film:

[0055] Wash the glass with glass water and deionized water, and treat it with a plasma cleaner for 2 minutes, and bake kerosene carbon black on the glass. Then dip the glass piece of baked carbon black into the prepared TiO 2 in sol-gel. Repeat the dip coating three times, immerse in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com