TBM gripper shoe concrete precast block device and gripper shoe tight-holding method

A technology of concrete and prefabricated blocks, which is applied in earthwork drilling, shaft equipment, shaft lining, etc. It can solve the problems that the full-section tunnel boring machine support shoes cannot be tightened, and achieve the effect of stable recovery of excavation construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following, the technical solutions of the present invention will be further described in detail through embodiments and in conjunction with the drawings.

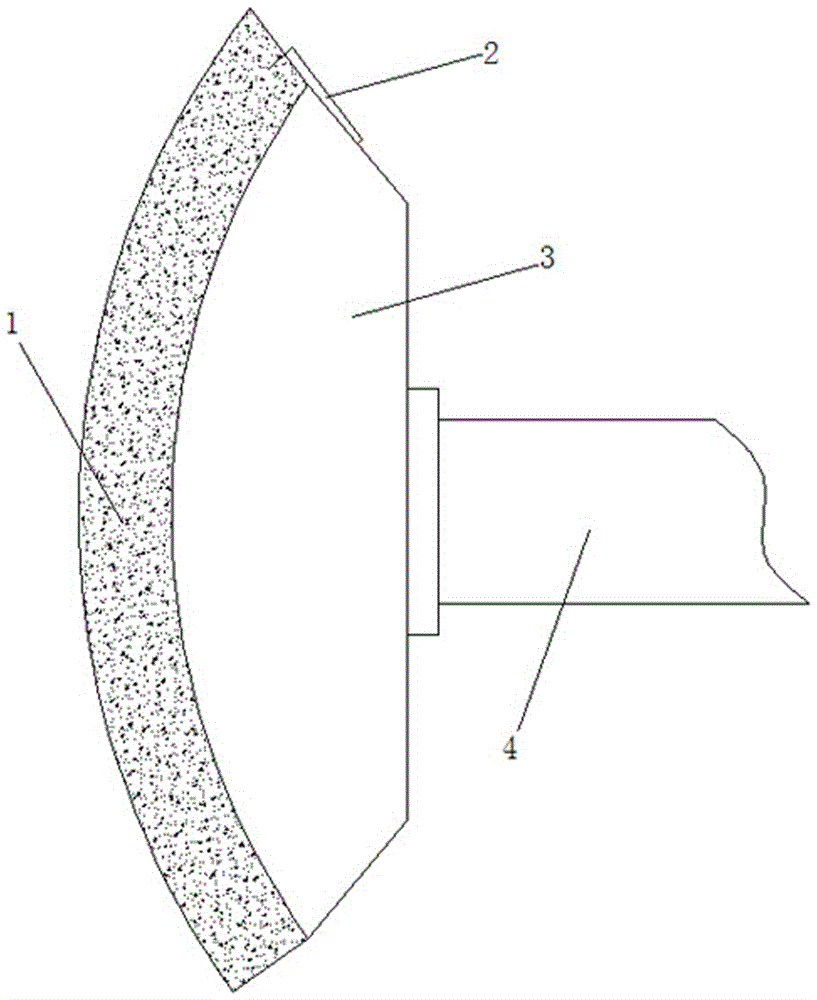

[0021] As shown in the figure, the present invention provides a TBM support shoe concrete precast block device, which is characterized in that it is made of steel and concrete, and the raw material used in the concrete is high-quality silicate with a strength grade of 52.5. The mass ratio of cement, quartz sand, fly ash, polycarboxylic acid water reducer, steel fiber, and water is: 1:1:0.5:0.09:0.18:0.18; the raw material used for the steel bar is the prestressed concrete screw thread Steel bars, of which: carbon content is 0.15%-0.3%, silicon content is 1.7%-1.9%, manganese content is 1.0%-1.2%, phosphorus content is less than 0.014%, sulfur content is less than 0.02%; the shape of TBM shoe concrete precast block 1 Matching with the shape of the support shoe 3, it also includes a fixed reinforcement member 2. On...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com