Additive for improving strength of potassium sulfate type compound fertilizer particles and preparation method for high-strength compound fertilizer particles

A technology of potassium sulfate type and compound fertilizer, which is applied in the direction of fertilization device, fertilizer mixture, application, etc., can solve the problems of increasing the cost of compound fertilizer raw materials, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] An additive for improving the particle strength of potassium sulfate type compound fertilizer, its raw material is 25%P by 200 parts of sulfuric acid, 100 parts of concentration 2 o 5 Dilute phosphoric acid, 300 parts mass concentration is 98% potassium sulfate solid composition.

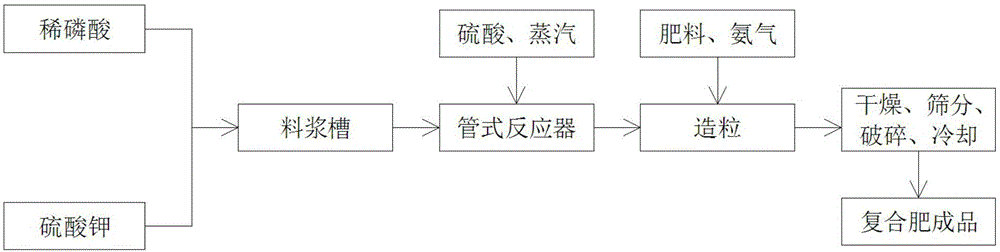

[0024] A preparation method for high-strength compound fertilizer granules, comprising the following steps:

[0025] 1. Take 100 parts of dilute phosphoric acid and 300 parts of potassium sulfate solid slurry tank, and stir to form a mixed slurry of potassium sulfate and dilute phosphoric acid;

[0026] 2. Feed the mixed slurry obtained above with 200 parts of sulfuric acid and steam into a tubular reactor for reaction to generate a large amount of high-temperature and high-pressure superheated steam to generate potassium bisulfate, potassium sulfate and phosphoric acid molten slurry;

[0027] 3. Send 1531 parts of powdered ammonium phosphate, 1769 parts of urea, 555 parts of ammonium sulfa...

Embodiment 2

[0032] An additive for improving the particle strength of potassium sulfate type compound fertilizer. Its raw materials are 160 parts of sulfuric acid and 100 parts of concentration of 20.78% P 2 o 5 Dilute phosphoric acid, 300 parts mass concentration is 98% potassium sulfate solid composition.

[0033] A preparation method for high-strength compound fertilizer granules, comprising the following steps:

[0034] 1. Take 100 parts of dilute phosphoric acid and 300 parts of potassium sulfate solid slurry tank, and stir to form a mixed slurry of potassium sulfate and dilute phosphoric acid;

[0035] 2. Feed the mixed slurry obtained above with 160 parts of sulfuric acid and steam into a tubular reactor for reaction to generate a large amount of high-temperature and high-pressure superheated steam to generate potassium bisulfate, potassium sulfate and phosphoric acid molten slurry;

[0036] 3. Send 2106 parts of powdered ammonium phosphate, 813 parts of urea, 906 parts of ammoni...

Embodiment 3

[0041] An additive for improving the particle strength of potassium sulfate type compound fertilizer, its raw material is 20%P by 140 parts of sulfuric acid, 100 parts of concentration 2 o 5 Dilute phosphoric acid, 100 parts mass concentration is 98% potassium sulfate solid composition.

[0042] A preparation method for high-strength compound fertilizer granules, comprising the following steps:

[0043]1. Take 100 parts of dilute phosphoric acid and 100 parts of potassium sulfate solid slurry in the tank, and stir to form a mixed slurry of potassium sulfate and dilute phosphoric acid;

[0044] 2. Feed the mixed slurry obtained above with 140 parts of sulfuric acid and steam into a tubular reactor for reaction to generate a large amount of high-temperature and high-pressure superheated steam to generate potassium bisulfate, potassium sulfate and phosphoric acid molten slurry;

[0045] 3. Send 2106 parts of powdered ammonium phosphate, 813 parts of urea, 932 parts of ammonium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com