Method for purifying tetrafluoroethylene from pyrolysis gas

A technology for purifying tetrafluoroethylene and pyrolysis gas, applied in the field of tetrafluoroethylene separation and purification, can solve the problem of high energy consumption, and achieve the effects of lowering the temperature of the tower kettle, lowering the energy consumption and reducing the pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

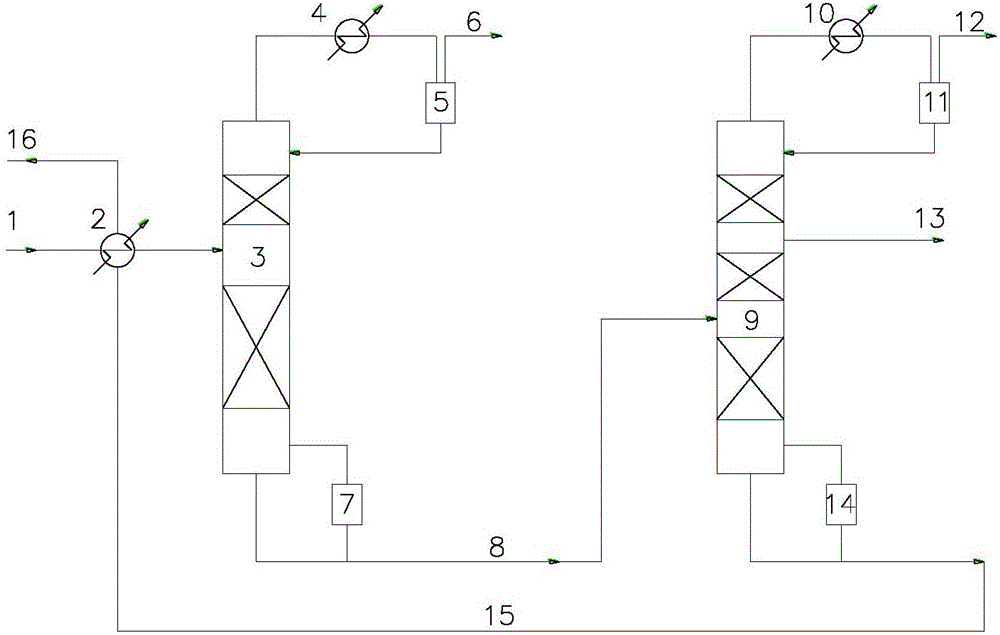

Method used

Image

Examples

Embodiment 1

[0025] Purification of 2300 kg per hour raw materials containing tetrafluoroethylene, the feed composition is as follows: trifluoromethane 0.08%, hexafluoroethane 0.002%, tetrafluoroethylene 45%, difluoromethane 0.418%, difluorochloromethane 39.5% , Hexafluoropropylene 15%.

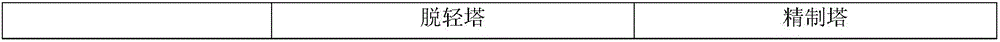

[0026] Operating conditions of each tower in the process flow

[0027]

[0028]

[0029] Note: After the heat exchange of raw materials, the temperature of entering the tower is 4°C

[0030] The main indicators of the phenazine product produced under the above-mentioned process conditions are as follows:

[0031]

Embodiment 2

[0033] Purification of 2300 kg per hour raw materials containing tetrafluoroethylene, the feed composition is as follows: trifluoromethane 0.1%, hexafluoroethane 0.0015%, tetrafluoroethylene 51.2%, difluoromethane 0.0985%, difluorochloromethane 38.2% , Hexafluoropropylene 10.4%.

[0034] Operating conditions of each tower in the process flow

[0035]

light tower

Refining tower

tower type

packed tower

packed tower

packing type

Stainless steel wire mesh structured packing

Stainless steel wire mesh structured packing

Theoretical progression

80

80

Operating pressure at the top of the tower (absolute pressure) / Kpa

1300

1200

Reflux ratio

1.1

1.1

[0036] Note: After the heat exchange of raw materials, the temperature of entering the tower is 4°C

[0037] The main indicators of tetrafluoroethylene products produced under the above process conditions are as follows:

[0038]

Embodiment 3

[0040] Purification of 2300kg per hour raw materials containing tetrafluoroethylene, the feed composition is as follows: trifluoromethane 0.35%, hexafluoroethane 0.05%, tetrafluoroethylene 60%, difluoromethane 1%, difluorochloromethane 30% , Hexafluoropropylene 8.6%.

[0041] Operating conditions of each tower in the process flow

[0042]

[0043]

[0044] Note: After the heat exchange of raw materials, the temperature of entering the tower is 4°C

[0045] The main indicators of tetrafluoroethylene products produced under the above process conditions are as follows:

[0046]

[0047] It can be seen from the above table that the present invention is feasible, and the whole separation process not only has simple process operation, low energy consumption, but also high separation efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com