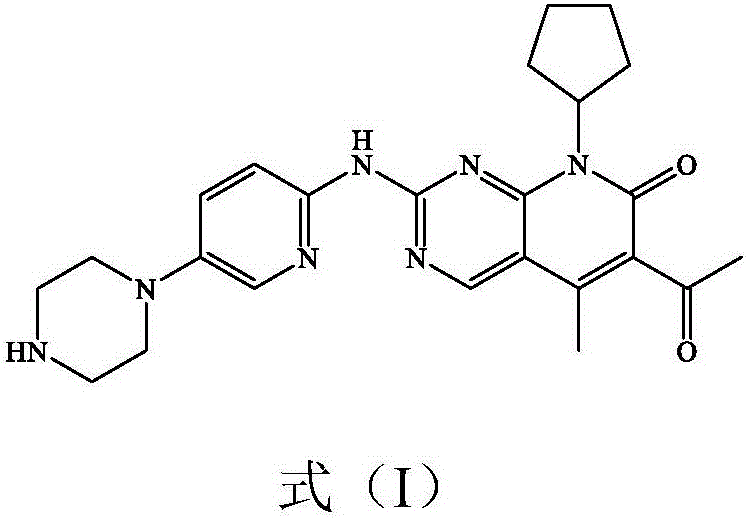

Palbociclib polycrystal form and preparation method thereof

A polymorph and crystal form technology, applied in organic chemistry methods, organic chemistry, etc., can solve the problems of excess residue on ignition and inability to guarantee pharmaceutical crystal forms, etc., achieves less solvent consumption, low production cost, and remarkable process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Preparation of palbociclib crystal form C:

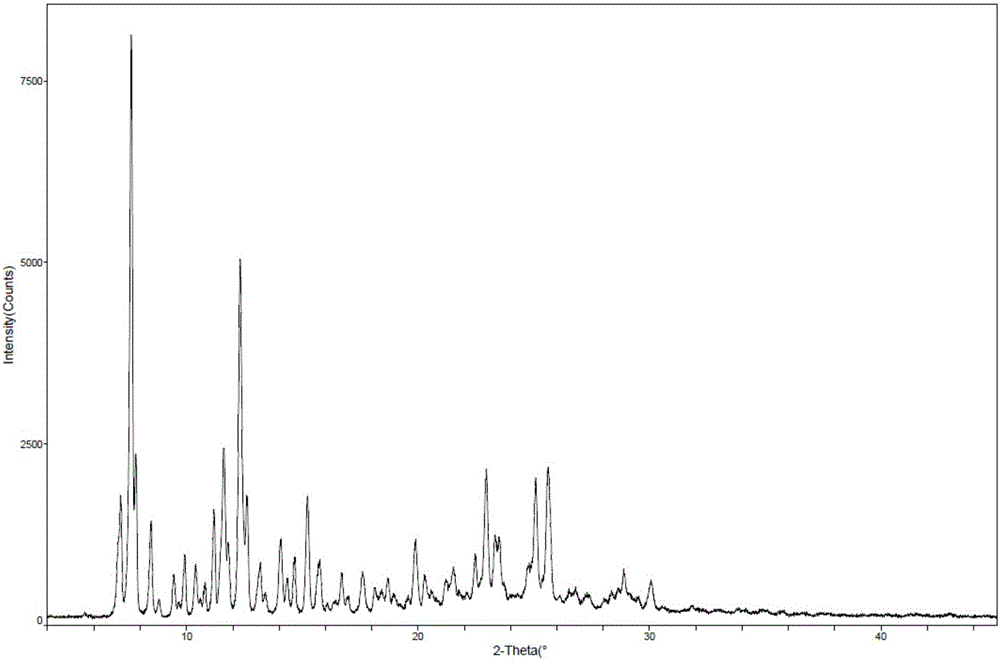

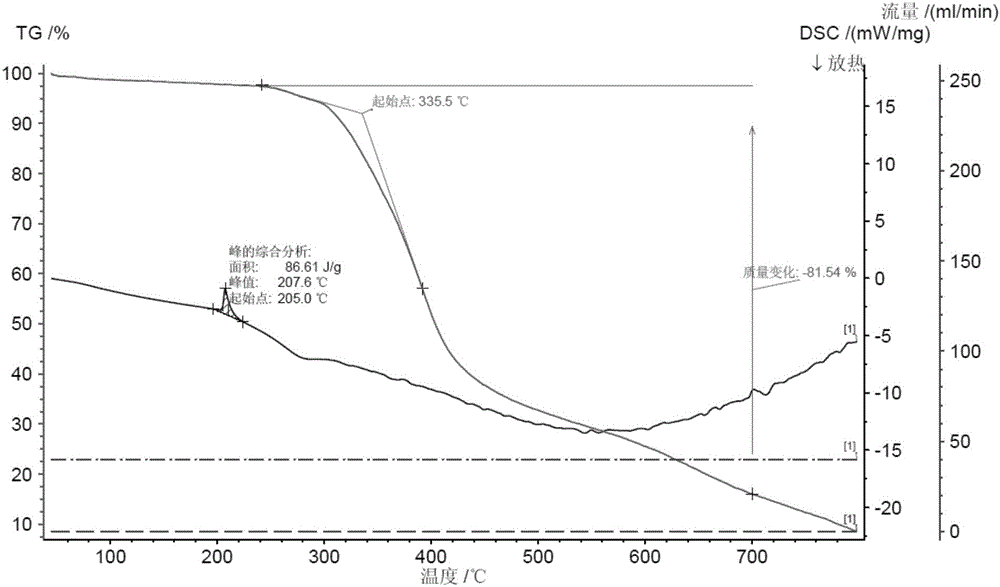

[0032] Add 5g of palbociclib into a 50ml three-neck flask, equipped with a thermometer, condensing device, oil bath and magnetic stirring, add 5ml of N,N-dimethylformamide and 30ml of acetone, magnetically stir, and heat to 60°C to completely dissolve, Stop heating, cool to room temperature for about 30 minutes, add 0.01g seed crystal, cool down to -10°C~0°C with ice machine, crystallize for 2~4h, filter with suction, wash the filter cake with a small amount of acetone, and vacuum dry at 35°C for 12 hours. 4.5 g of white crystals were obtained, yield: 90%, purity: 99.8%. The X-ray powder diffraction pattern of white crystals is shown in figure 1 , see the TG / DSC analysis chart figure 2 .

Embodiment 2

[0034] Add 5g of palbociclib into a 50ml three-neck flask, equipped with a thermometer, condensing device, oil bath and magnetic stirring, add 5ml of dichloromethane and 20ml of ethanol, stir magnetically, heat to 55°C to dissolve completely, stop heating for about 30 minutes Cool to room temperature, add 0.01g seed crystal, cool down to -20°C~-10°C with an ice machine, crystallize for 2~4 hours, filter with suction, wash the filter cake with a small amount of acetone, and vacuum dry at 35°C for 12 hours to obtain 4.3g of white crystals , yield: 86%, purity: 99.7%.

Embodiment 3

[0036] Add 5 g of palbociclib into a 100 ml three-neck flask, equipped with a thermometer, condensing device, oil bath, and magnetic stirring, add 5 ml of N,N-dimethylformamide and 50 ml of ethanol, stir magnetically, and heat to 40°C to completely dissolve. Stop heating, cool to room temperature for about 30 minutes, add 0.01g seed crystals, cool down to 0°C-10°C with an ice machine, crystallize for 2-4 hours, filter with suction, wash the filter cake with a small amount of acetone, and dry under vacuum at 40°C for 12 hours to obtain 4.1 g of white crystals, yield: 82%, purity: 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com