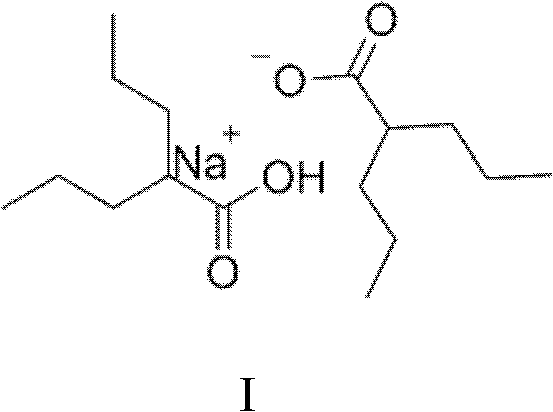

Method for preparing divalproex sodium

A technology of divalproex sodium and valproic acid, which is applied in carboxylate preparation, organic chemistry, etc., can solve the problems such as the purity of divalproex sodium and achieve excellent fluidity, low cost and short cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

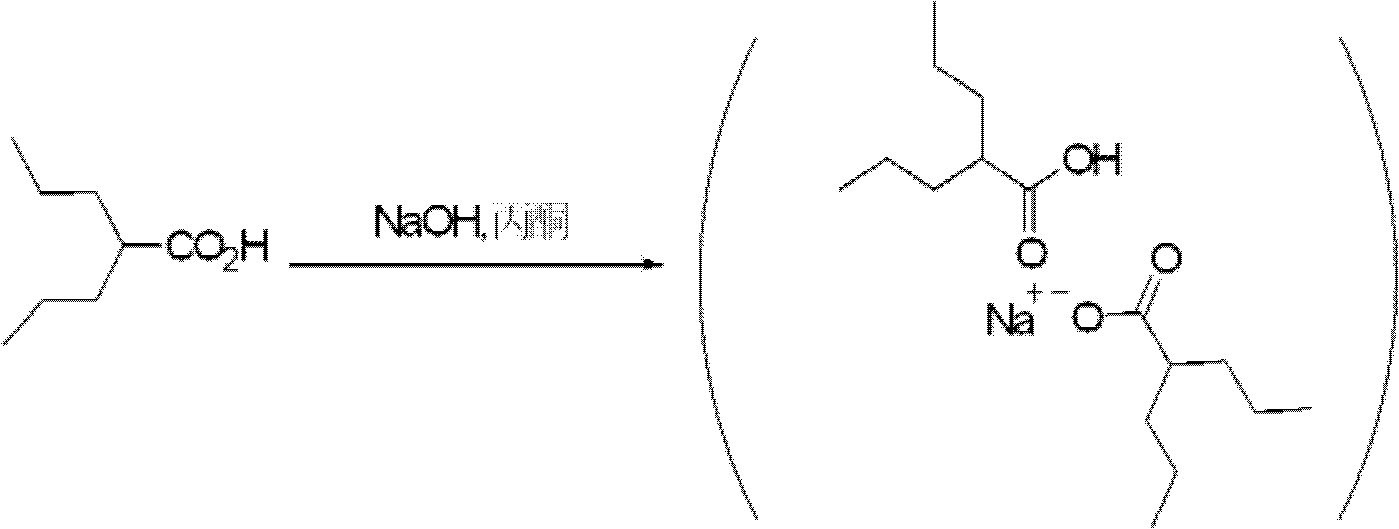

Method used

Image

Examples

Embodiment 1

[0051]

[0052] At room temperature, in 1000ml four-neck flask, add 750ml acetone, 73.7g (0.512mol, 1.0eq (molar equivalent)) valproic acid, then add 10.4g (0.26mol, 0.5eq) sodium hydroxide solid, stir until solid The mixture was completely dissolved, and the mixed system was frozen and crystallized at -15°C overnight, and then the obtained solid was filtered with suction, and the filter cake was washed with a small amount of cold acetone to obtain 75.1 g of a white solid with a yield of 95% and an HPLC purity of 99.86 %.

[0053] HNMR (CDCl 3 , ppm): δ13.16 (brs, 1H), 2.25-2.19 (m, 2H), 1.45-1.57 (m, 4H), 1.21-1.39 (m, 12H), 0.86 (t, J=7.2Hz, 12H ).

Embodiment 2

[0055] At room temperature, in 1000ml four-neck flask, add 600ml acetone, 37.9g (0.263mol, 1.0eq) valproic acid, then add 5.3g (0.13mol, 0.5eq) sodium hydroxide solid, stir until the solid is completely dissolved, and The mixed system was frozen and crystallized at -12°C overnight, and then the obtained solid was suction-filtered, and the filter cake was washed with a small amount of cold acetone to obtain 38.0 g of a white solid with a yield of 93.2% and an HPLC purity of 99.15%.

Embodiment 3

[0057] At room temperature, in the 1500ml four-necked flask, add the mixed solution of 850ml acetone and acetonitrile (acetone: acetonitrile=3:1 (V / V)) and 71.6g (0.497mol, 1.0eq) valproic acid, then add 9.9g (0.25mol, 0.5eq) sodium hydroxide solid, stirred until the solid was completely dissolved, placed the mixed system at -5°C for freezing and crystallization overnight, then suction filtered the resulting solid, and washed the filter cake with a small amount of cold acetone to obtain 66g white solid, yield 85.6%, HPLC purity 99.03%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| angle of repose | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com