Two-component heat conducting silicon grease capable of being prepared in a gelatinization mode under normal temperature or heating condition and preparing method thereof

A heat-conducting silicone grease and heat-conducting filler technology, applied in chemical instruments and methods, heat exchange materials, coatings, etc., can solve the problems of reduced heat conduction effect, powdery, cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0103] This embodiment provides a thermally conductive silicone grease prepared from component A and component B, wherein the weight ratio of component A to component B is 0.5:1.

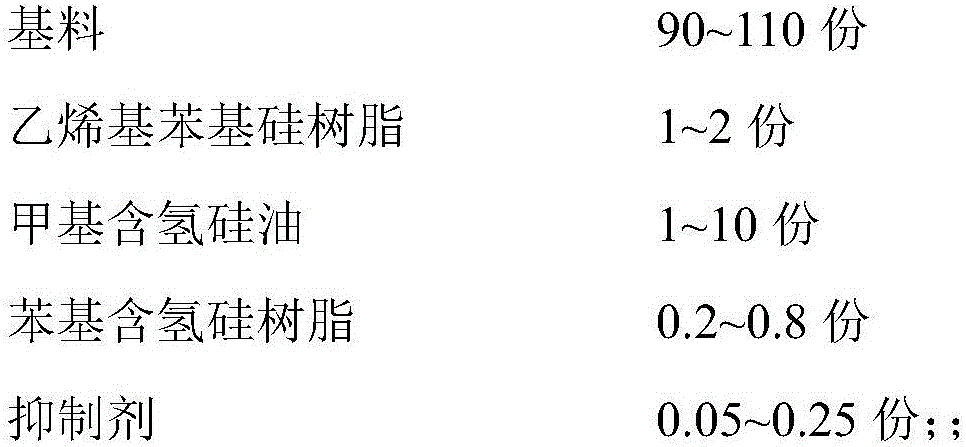

[0104] The A component was prepared from the following weights of raw materials:

[0105]

[0106] The above vinyl phenyl silicone resin was purchased from Zhejiang Runhe Silicone New Material Co., Ltd., the model is RH-SP606, and it has the following structural formula:

[0107] The above-mentioned methyl hydrogen-containing silicone oil was purchased from Zhejiang Runhe Silicone New Material Co., Ltd., the model is RH-H503, and it has the following molecular formula: Si(CH 3 ) 3 -[OSi(H)(CH 3 )] 10 -[OSi(CH 3 ) 2 ] 30 -OSi(CH 3 ) 2 .

[0108] The above-mentioned phenyl hydrogen-containing silicone resin was purchased from Zhejiang Runhe Silicone New Material Co., Ltd., the model is RH-SH309, and it has the following molecular formula: Si(CH 3 ) 3 -[OSi(H)(CH 3 )] 35 -[OSi(C 6 h ...

Embodiment 2

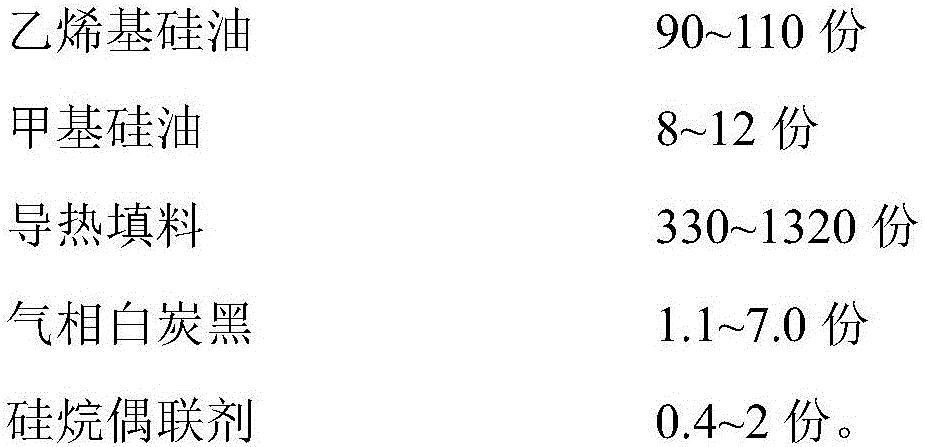

[0129] This example provides a thermally conductive silicone grease, which is prepared from component A and component B, wherein the weight ratio of component A to component B is 0.5:1, except for the base material, component A and component B The preparation raw materials of part are all with embodiment 1, and the base material in A component and B component is prepared by the raw material of following weight:

[0130]

[0131]

[0132] The above-mentioned vinyl silicone oil was purchased from Zhejiang Runhe Silicone New Material Co., Ltd., the model is RH-Vi322, and it has the following molecular formula:

[0133] CH 2 =CHSiO(CH 3 ) 2 -[SiO(CH 3 ) 2 )] 60 -[SiO(CH 3 )(CH=CH 2 )] 40 -Si(CH 3 ) 2 CH=CH 2 .

[0134] The above-mentioned methyl silicone oil was purchased from Jiangxi Xinghuo Organic Silicon Co., Ltd., with a viscosity of 100cs and the following molecular formula: (CH 3 ) 3 SiO-[SiO(CH 3 ) 2 ] 50 -Si(CH 3 ) 3 .

[0135] The above-mentione...

Embodiment 3

[0141] This embodiment provides a thermally conductive silicone grease, which is prepared from component A and component B, wherein the weight ratio of component A to component B is 0.5:1, except for the base material, the component B Preparation of raw materials is the same as in Example 1.

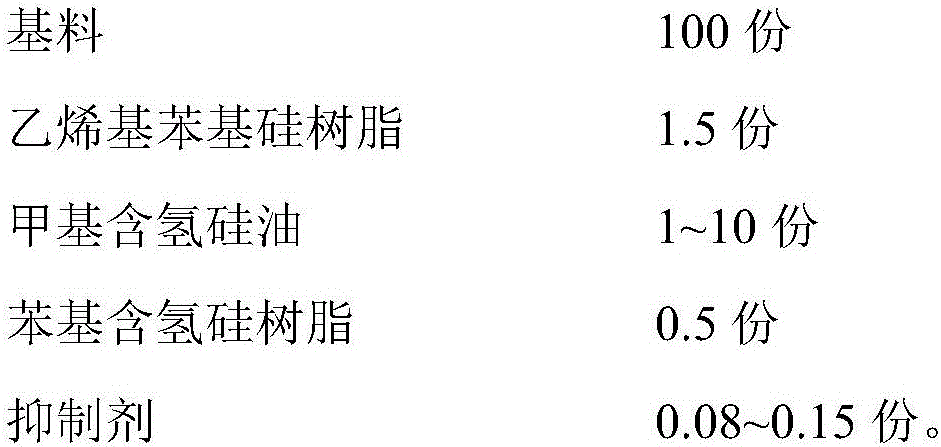

[0142] The A component was prepared from the following weights of raw materials:

[0143]

[0144] The above vinyl phenyl silicone resin was purchased from Zhejiang Runhe Silicone New Material Co., Ltd., the model is RH-SP606, and it has the following structural formula:

[0145] The above-mentioned methyl hydrogen-containing silicone oil was purchased from Zhejiang Runhe Silicone New Material Co., Ltd., the model is RH-H503, and it has the following molecular formula: Si(CH 3 ) 3 -[OSi(H)(CH 3 )] 10 -[OSi(CH 3 ) 2 ] 30 -OSi(CH 3 ) 2 .

[0146] The above-mentioned phenyl hydrogen-containing silicone resin was purchased from Zhejiang Runhe Silicone New Material Co., Ltd., t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central particle size | aaaaa | aaaaa |

| Central particle size | aaaaa | aaaaa |

| Central particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com