Flexible super capacitor and preparation method of flexible super capacitor

A supercapacitor, flexible technology, used in the manufacture of hybrid capacitor electrolytes and hybrid/electric double-layer capacitors, etc., can solve the problems of small electrochemical window, flammability, and complex process of electrolyte, and achieve a wide range of voltage and temperature applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

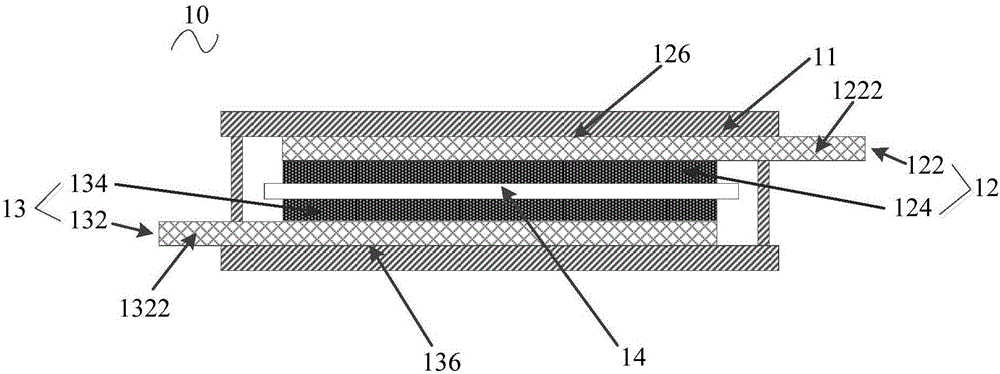

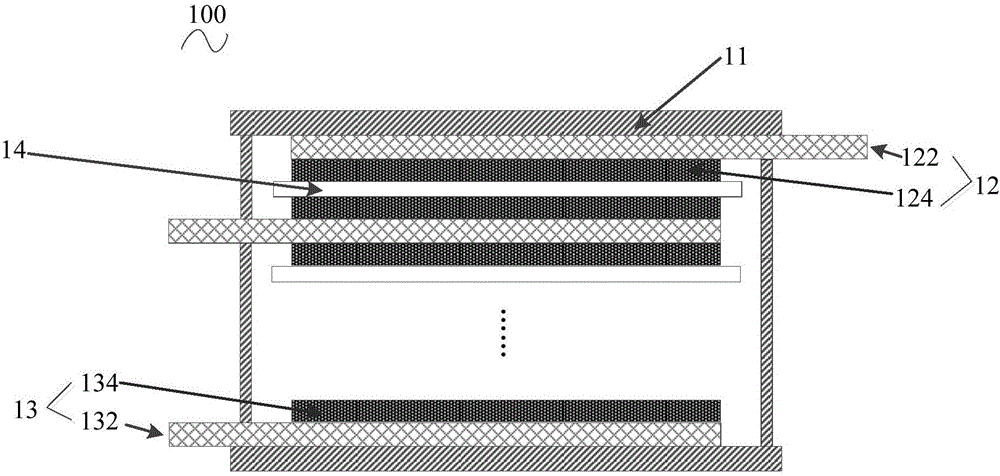

[0087] see Figure 4 , the preparation method of the flexible supercapacitor 10 of the embodiment of the present invention, comprising:

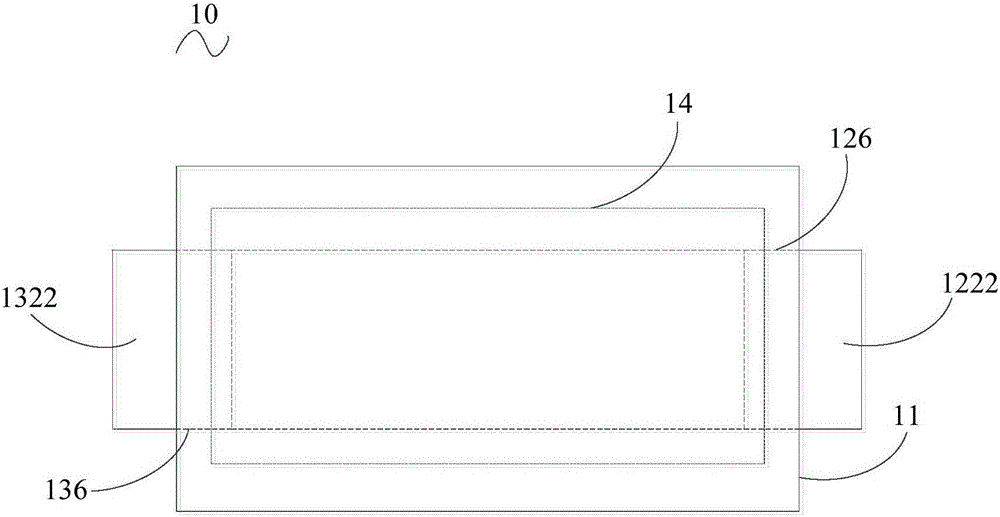

[0088] Step S10, provide packaging film 11, first electrode 12 and second electrode 13, first electrode 12 includes first pole piece 122, second electrode 13 includes second pole piece 132, first pole piece 122 and second pole piece 132 is made of the same material;

[0089] Step S20, soaking the separator in the gel electrolyte of the ionic liquid and then absorbing the gel electrolyte to prepare the electrolyte film 14; and

[0090] Step S30, disposing the first electrode 12 and the second electrode 13 on opposite sides of the electrolyte membrane 14 and pressing them tightly;

[0091] Step S40 , encapsulating the electrolyte film 14 with the first electrode 12 and the second electrode 13 with the encapsulation film 11 .

[0092] The method for preparing the flexible supercapacitor 10 according to the embodiment of the present invention...

Embodiment 1

[0137] Activated carbon: Ketjen black: PVDF is used to prepare the slurry according to the mass ratio of 80:10:10, and then coat it on the current collector aluminum foil as the first pole piece 122 and the second pole piece 132, dry and cut it into 40mm* 50mm. Mix 1-ethyl-3-methylimidazole bistrifluoromethanesulfonimide salt, polyethylene oxide and benzophenone at a ratio of 10:1:0.05, heat to 100°C and keep it warm for two hours, and irradiate with UV for 4 minutes. The gel electrolyte can be obtained, and the electrolyte film 14 is obtained by soaking the non-woven membrane FPC3018 in the gel electrolyte. A: B of PMDS is mixed at a mass ratio of 10:1 to remove air bubbles and form a film.

[0138] The first electrode 12, the second electrode 13 and the electrolyte film 14 are made into a sandwich structure for supercapacitance under the action of 1 MPa. Finally, after the film-formed PDMS is treated with oxygen plasma, the supercapacitor is sandwiched up and down, and bon...

Embodiment 2

[0140] Adopt carbon nanotubes: Ketjen black: PVDF to prepare slurry by mass ratio 60:30:10, then apply it on the current collector aluminum foil as the first pole piece 122 and the second pole piece 132, dry and cut into 60mm*80mm. Mix 1-butyl-1-methylpyrrolidine bistrifluoromethanesulfonimide salt, polyethylene oxide and benzophenone at a ratio of 15:1:0.05, heat to 120°C and keep it warm for 24 hours, and irradiate with UV light for 10 minutes. The gel electrolyte can be obtained, and the electrolyte film 14 is obtained by coating the gel electrolyte on both sides of the cellulose diaphragm TF48.

[0141] The first electrode 12, the second electrode 13 and the electrolyte film 14 are made into a sandwich structure for supercapacitance under the action of 2 MPa. Finally, sandwich the supercapacitor up and down with the PET film coated with EVA particles, and glue and package it under a hot press at 120°C and 1Mpa to obtain the flexible supercapacitor 10 according to the embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Heat resistant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com