Step-down power supply ripple detection and compensation circuit

A power supply ripple and compensation circuit technology, which is applied in power supply testing, electrical components, AC/pulse peak measurement, etc., can solve problems such as short service life and small electrolytic capacitors, and achieve extended service life, strong stability, and realization of ripple The effect of wave current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

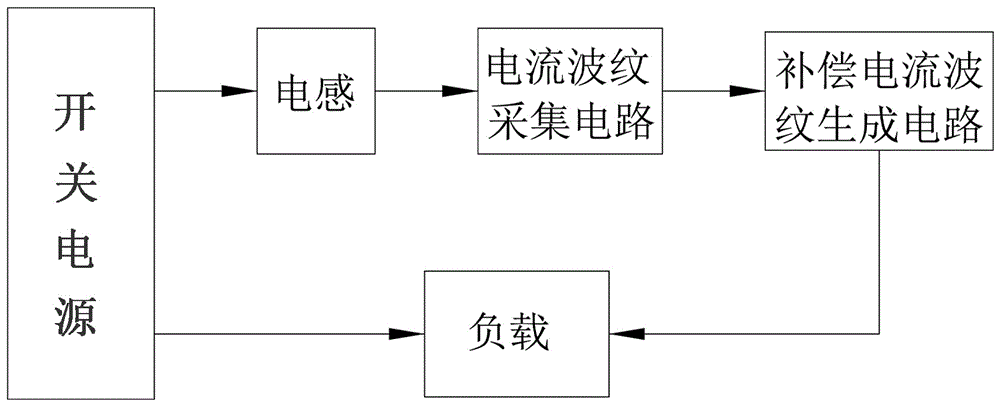

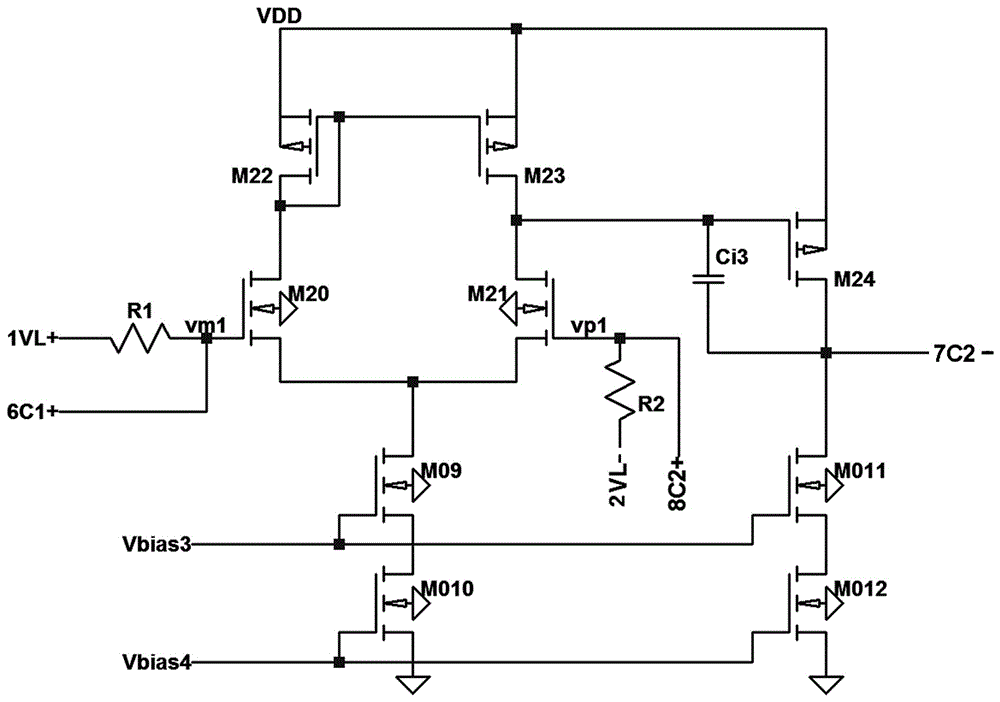

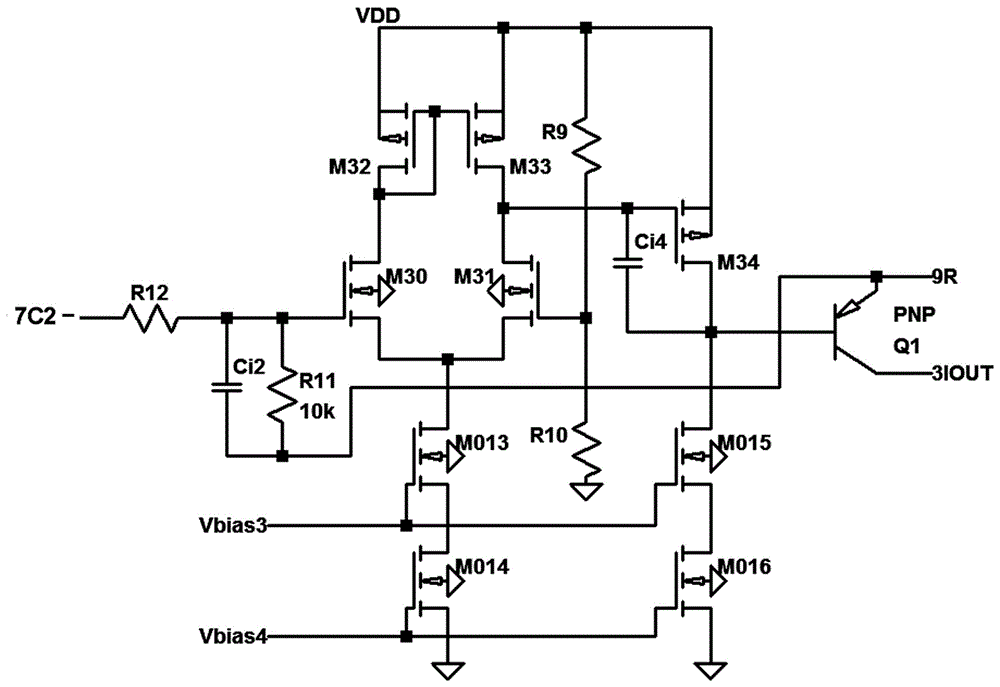

[0018] refer to Figure 1 to Figure 4 , a step-down power supply ripple detection and compensation circuit, connected in parallel with a load behind a DC / DC or AC / DC switching power supply, including: a current ripple acquisition circuit: connected to the inductance L1 of the switching power supply, for collecting the inductance the voltage change signal. Compensation current ripple generation circuit: the input terminal is connected to the output terminal of the current ripple acquisition circuit, and the output terminal is connected to the input terminal of the load, for generating a compensation current opposite to the inductor current of the switching power supply, and superimposed on Input to load LOAD.

[0019] For the schematic circuit diagram of this embodiment, see Figure 2 to Figure 4 , the current ripple acquisition circuit includes an internal circuit and an external circuit. The internal circuit includes a resistor R1, a resistor R2, a capacitor Ci3, an NMOS t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com