In-situ fibrillation technology-based degradable polymeric blend material, and preparation method and application thereof

An in-situ fiber-forming and polymer technology, applied in surgery, medical science and other directions, can solve problems such as difficulty in realization, and achieve the effects of scientific design, simple operation process and simple preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

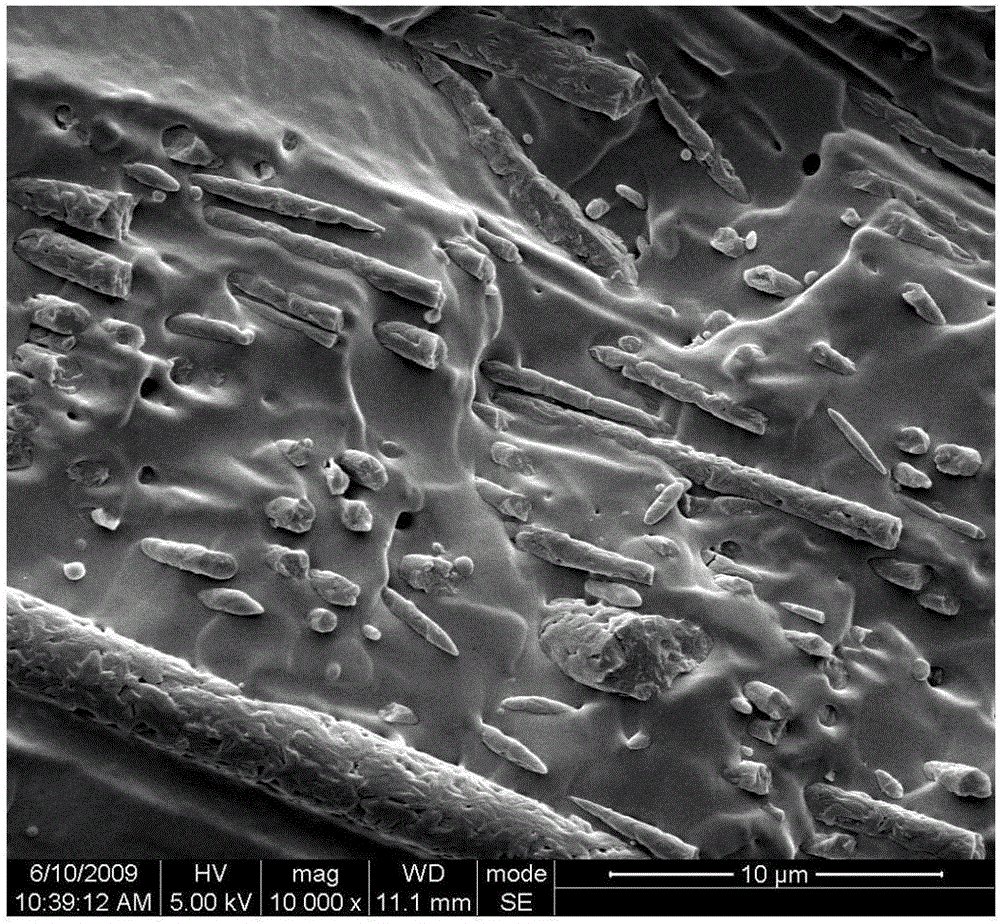

[0035] Polytrimethylene carbonate (weight-average molecular weight: 350,000) and polyglycolide (weight-average molecular weight: 200,000) were melt-extruded using a melt extruder, and polyglycolide / polytrimethylene carbonate was 5 / 95, The extrusion temperature was 220°C, and the diameter of the extrudate was about 0.5 mm. The extrudate was stretched with a stretching machine, cooled to room temperature, and then cut into degradable lacrimal plugs with a length of about 3.0mm cylinders using a cutting machine. Electron microscope scanning was performed on the degradable lacrimal embolus prepared in Example 1. As can be seen from the figure, the polyglycolide in the degradable lacrimal embolus is distributed in the form of fibers in the polytrimethylene carbonate.

[0036] According to the in vitro degradation test, the lacrimal plug prepared in this example can be completely degraded after 25 weeks.

Embodiment 2

[0038] Polytrimethylene carbonate (weight-average molecular weight: 500,000) and polyglycolide (weight-average molecular weight: 300,000) were melt-extruded using a melt extruder, and polyglycolide / polytrimethylene carbonate was 8 / 92, The extrusion temperature was 225°C, and the diameter of the extrudate was about 0.3 mm. The extrudate was stretched with a stretching machine, cooled to room temperature, and then cut into degradable lacrimal plugs with a length of about 2.5mm cylinders using a cutting machine.

[0039] According to the in vitro degradation test, after 26 weeks, the lacrimal plug prepared in this example can be completely degraded.

Embodiment 3

[0041] Polytrimethylene carbonate (weight-average molecular weight: 200,000) and polyglycolide (weight-average molecular weight: 150,000) were melt-extruded by a melt extruder, and polyglycolide / polytrimethylene carbonate was 12 / 88, The extrusion temperature was 230°C, and the diameter of the extrudate was about 0.40 mm. The extrudate was stretched with a stretching machine, cooled to room temperature, and then cut into degradable lacrimal plugs with a length of about 3.0mm cylinders using a cutting machine.

[0042] According to the in vitro degradation experiment, after 22 weeks, the lacrimal plug prepared in this example can be completely degraded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com