Chitosan-oyster shell composite microsphere and preparation method thereof

A technology of composite microspheres and chitosan, which is applied in chemical instruments and methods, alkali metal compounds, and other chemical processes, can solve the problems of inconspicuous modification of oyster shells, low removal rate, and inconspicuous water treatment capabilities, etc. problem, achieve the effect of preventing sedimentation and coagulation, good absorption effect, and improving surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

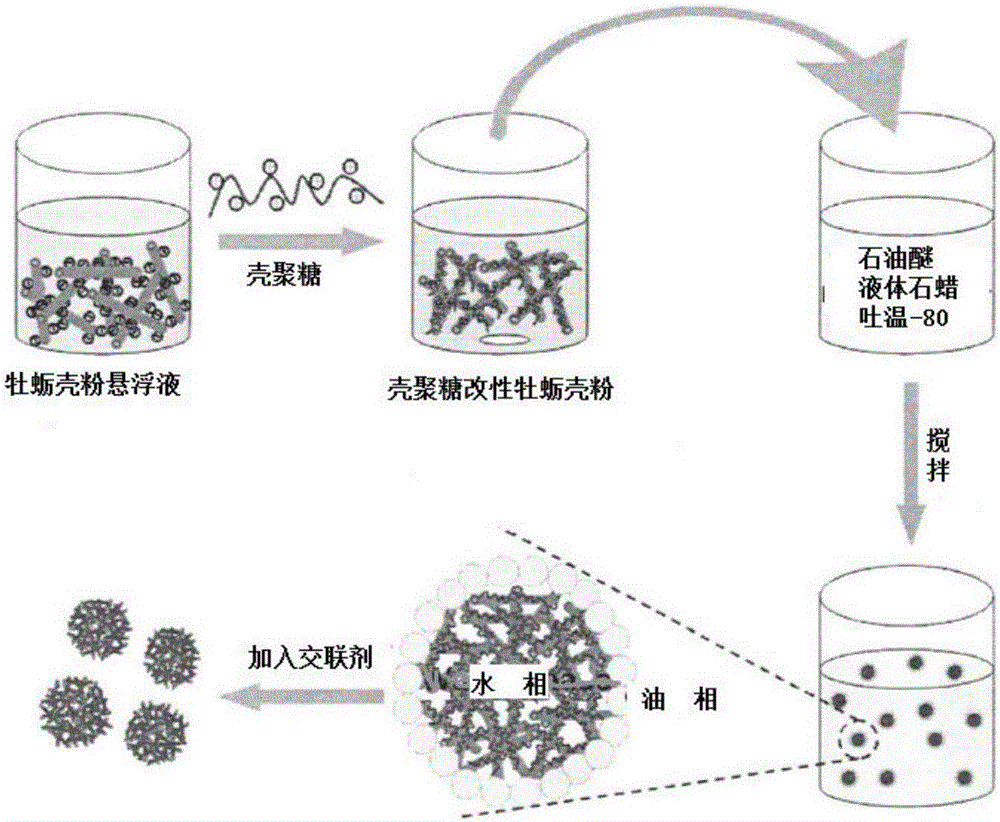

[0033] The invention provides a kind of preparation method of chitosan-oyster shell composite microsphere, comprises the following steps:

[0034] (1) mixing scallop powder, oyster shell powder and water to obtain a safflower-oyster shell suspension;

[0035] (2) the suspension obtained in the step (1) is mixed with an aqueous solution of chitosan to obtain a composite solution of chitosan-squat-oyster shell;

[0036] (3) the chitosan-squat-oyster shell composite solution obtained in the step (2) is mixed with a dispersant, an emulsifier and an oil phase to obtain an emulsion containing water-in-oil droplets;

[0037] (4) Mix the emulsion obtained in the step (3) with a glutaraldehyde-saturated toluene solution to carry out a cross-linking reaction to obtain chitosan-oyster shell composite microspheres.

[0038] The scallop powder, oyster shell powder and water are mixed to obtain the scallop-oyster shell suspension. In the present invention, the addition of the oyster shell...

Embodiment 1

[0071] (1) The oyster shells were first washed with 2mol / L hydrochloric acid, crushed and passed through a 100-mesh sieve to obtain oyster shell powder, dried in a muffle furnace at 200°C for 3 hours, and sealed for storage. Weigh 5g of oyster shell powder and add it to 200ml of deionized water, add 0.5g of oyster shell powder with a particle size of 100 mesh, and ultrasonically disperse with a power of 1000w for 2 hours to obtain a uniform suspension;

[0072] (2) Take 2g chitosan and add it into 100ml deionized water containing 5ml glacial acetic acid, carry out magnetic stirring for 10 hours with the rotating speed of 500rpm to make chitosan dissolve completely to obtain a transparent viscous solution;

[0073] (3) Slowly add the obtained chitosan solution into 120ml of oyster shell powder suspension under the magnetic stirring condition of 250rpm rotating speed, and continue to stir for 24 hours to obtain chitosan modified oyster shell powder solution.

[0074] (4) Add 40mL ...

Embodiment 2

[0078] (1) The oyster shells were washed with 5 mol / L hydrochloric acid first, crushed and passed through a 100-mesh sieve to obtain oyster shell powder, dried in a muffle furnace at 250°C for 2 hours, and sealed for storage. Weigh 5g of oyster shell powder and add it to 200ml deionized water, add 0.5g of oyster shell powder with a particle size of 100 mesh, and ultrasonically disperse for 2 hours under the condition of 1000w to obtain a uniform suspension;

[0079] (2) Take 2g carboxymethylated chitosan and add it into 100ml deionized water containing 6ml glacial acetic acid, and magnetically stir at a rotating speed of 1000rpm for 10 hours to completely dissolve chitosan to obtain a transparent and viscous solution;

[0080] (3) The chitosan solution obtained is slowly added to the oyster shell powder suspension obtained in the step (1) of 140ml under the stirring condition of the rotating speed of 400rpm, and continued to stir for 24 hours to obtain the chitosan modified oys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com