Non-contact heating tin-lead soldering method for metallic structural part and PCB (Printed Circuit Board)

A metal structure, non-contact technology, used in metal processing equipment, welding equipment, electric heating devices, etc., can solve the problem of inability to solve the heat absorption effect of metal structures, improve welding efficiency, fully infiltrate, and ensure welding quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

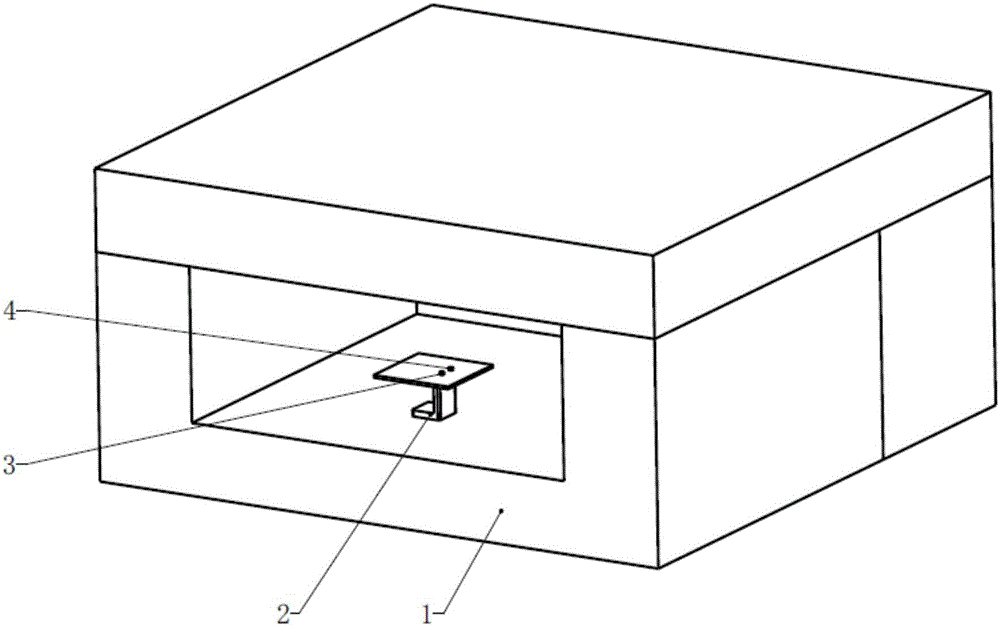

Embodiment 1

[0029] The preset workpiece step specifically includes:

[0030] Take out the metal structural parts from the turnover box and put them on the turnover fixture with the function of limiting and positioning, so that the metal structural parts can be placed according to the predetermined position.

[0031] Carry out plug-in gap assembly between the PCB and the metal structure; ensure that after the assembly is in place, a platform-like support is used around the PCB to smoothly fix the PCB on the metal structure. This kind of support adopts a multi-array overall structure fixing method, which can ensure the assembled state of each PCB and metal structural parts, and provide effective and reliable fixation in multiple directions to ensure the consistency of the welding effect. The support has the characteristics of high temperature resistance, which prevents the supporting failure during the overall heating process due to the thermal expansion and contraction effect of the object...

Embodiment 2

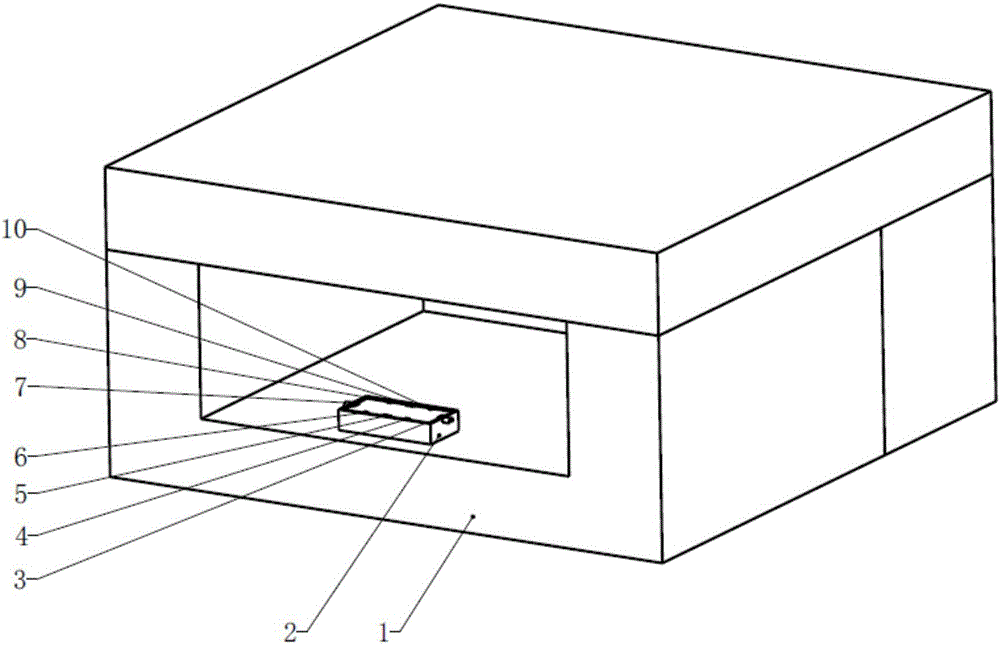

[0041] Such as figure 2 As shown, the soldering method of the first embodiment is similar to that of the first embodiment, the difference lies in the preset process of the workpiece. Specifically reflected in:

[0042] In this embodiment, the PCB is first taken out from the turnover box, and the corresponding front and back sides are separated. Then put the side of the PCB that needs to be soldered into the turnover fixture with pre-positioning function. At the same time, corresponding overall positioning of all PCB boards is carried out through the die tooling. The overall pre-positioned structural tooling of the die tooling can ensure the effective and reliable fixation of multiple PCBs, and at the same time ensure that the mutual position between the PCBs does not exceed ±0.1mm to ensure the consistency of the welding effect. The mold tooling with pre-positioning function has high temperature resistance, which prevents the deformation of the positioned PCB due to the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com