Ammonium phosphate slurry filter unit and filter method thereof

A filtration method and a technology of a filtration device, which are applied in the direction of filtration separation, separation method, chemical instrument and method, etc., can solve problems such as high investment and energy consumption, inconvenient cleaning of filter cloth, and low equipment start-up rate, so as to improve the purity of ammonium phosphate , Avoid filtration difficulty, low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

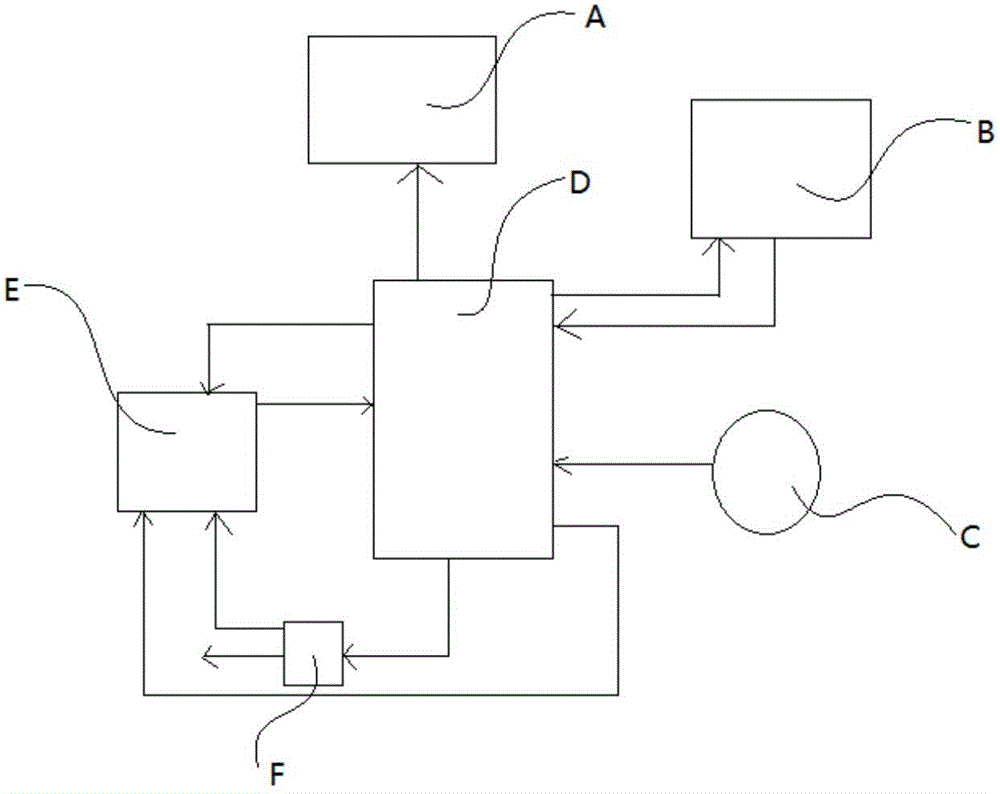

[0030] Concrete principle of the present invention and specific mode of operation are carried out in the following manner, and those skilled in the art can understand the overall scheme of the present invention according to the following contents:

[0031] A method for filtering ammonium phosphate slurry, comprising the following steps:

[0032] (1) In the slurry tank E, the slurry of the neutralization reaction of wet-process phosphoric acid and ammonia is formulated to have a pH value of 3-5, a temperature of 70-90°C, a solid content of 1-2%, and a specific gravity of ammonium phosphate Ammonium phosphate slurry of 1.1-1.3;

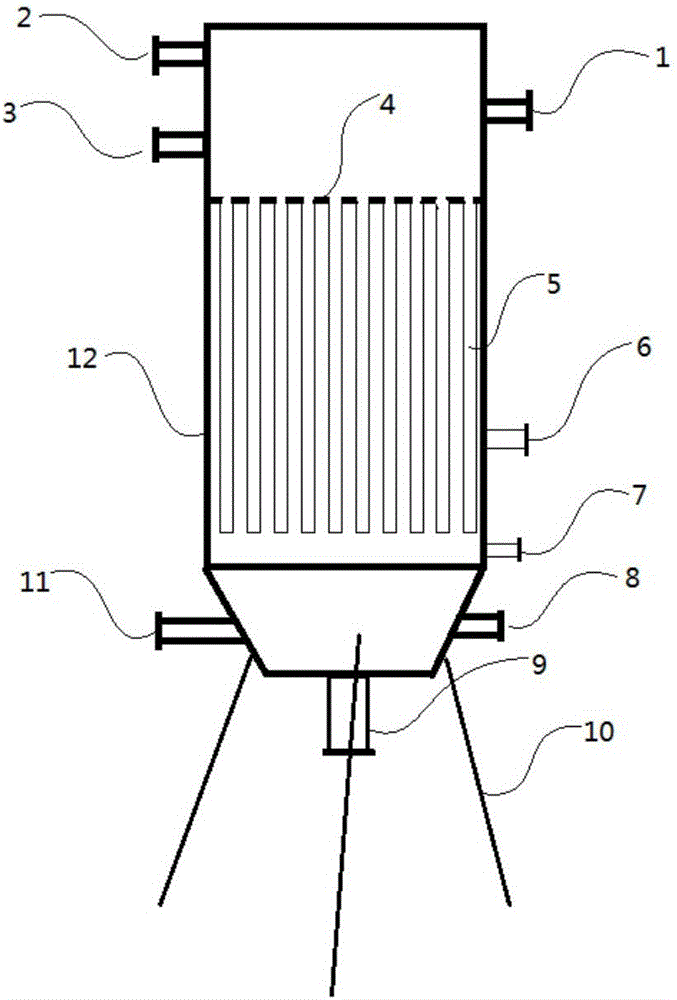

[0033] (2) Send the ammonium phosphate slurry into the filter device D, and process it through aeration and reverse osmosis filtration, so that the filtrate of the ammonium phosphate slurry enters the filter bag 5 of the filter device D, and the filter residue of the ammonium phosphate slurry stays in the filter device D The outer surface of the filter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com