Process for producing polyaluminum ferric chloride by gasifier ash

A technology of polyaluminium-ferric chloride and gasifier ash, which is applied in iron halides, chemical instruments and methods, water/sewage treatment, etc., and can solve the problems of low COD removal rate, low product yield, and product sewage treatment. Low turbidity removal rate and other problems, to achieve the effect of saving raw materials, low reaction temperature, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Example 1 A process for producing polyaluminum ferric chloride by utilizing gasifier ash slag

[0036] Step 1 raw material selection

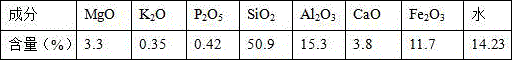

[0037] The raw material adopted is the gasifier ash slag discarded by the chemical plant, and the composition of the gasifier ash slag is shown in Table 1:

[0038] Table 1 Composition of gasifier ash

[0039]

[0040] After drying the gasifier ash, grind it into 80-mesh powder for later use.

[0041] Step 2 Leach

[0042] Add gasifier ash powder into water, add 50g ash powder per liter of water, heat to 45°C, keep for 15 minutes, stir at 2200rpm for 30min, let it stand for 4 hours, pass through a pressure filter device at a passing speed of 480L / min , the pressure is 0.5 MPa, and the filter residue is collected.

[0043] Step 3 pickling

[0044] The filter residue is dropped into the reactor, and the acid solution is added in the reactor, and the mass ratio of the filter residue and the acid solution is 31:77;

[0045] The acid...

Embodiment 2

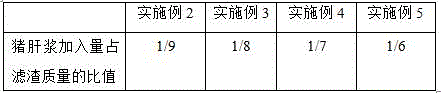

[0052] Example 2 Single factor analysis experiment of pig liver slurry addition

[0053] Adopt the technology of embodiment 1, only change the addition amount of pig liver slurry in the pickling step and carry out embodiment 2-5; The addition amount of pig liver slurry adopted in embodiment 2-5 is shown in Table 2;

[0054] The pig liver slurry addition amount that adopts in the embodiment 2-5 of table 2

[0055]

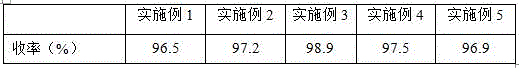

[0056] The yield of the polyaluminum ferric chloride solid product prepared by the technique of Embodiment 1-5 is shown in Table 3;

[0057] Table 3 The yield of polyaluminum ferric chloride solid product

[0058]

[0059] It can be seen from Tables 2 and 3 that the pig liver slurry added in the pickling step is preferably 1 / 8 of the filter residue quality.

Embodiment 6

[0060] Embodiment 6 reaction temperature single factor analysis experiment

[0061] Adopt the technology of embodiment 1, only change the reaction temperature in the pickling step and carry out embodiment 6-9; The reaction temperature that adopts among the embodiment 6-9 is shown in Table 4;

[0062] The reaction temperature that adopts in the embodiment 6-9 of table 4

[0063]

[0064] The polyaluminum ferric chloride solid product prepared by the process of Example 6-9 is used as a coagulant to detect sewage treatment performance;

[0065] The test results are shown in Table 5;

[0066] Table 5 adopts the coagulant of embodiment 6-9 to carry out sewage treatment result

[0067]

[0068] It can be seen from Tables 4 and 5 that the reaction temperature is preferably 78°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com