Houttuynia cordata and caraway edible instant packaging film, flavoring bag and preparation method thereof

A technology of folding ear root and packaging film, which is applied in the field of edible instant packaging film of folding ear root coriander, can solve the problems of consumers' troubles, difficulty in tearing, and oil sauce package full of oil, etc., and achieves simple preparation process, easy popularization and application, The effect of not easy oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

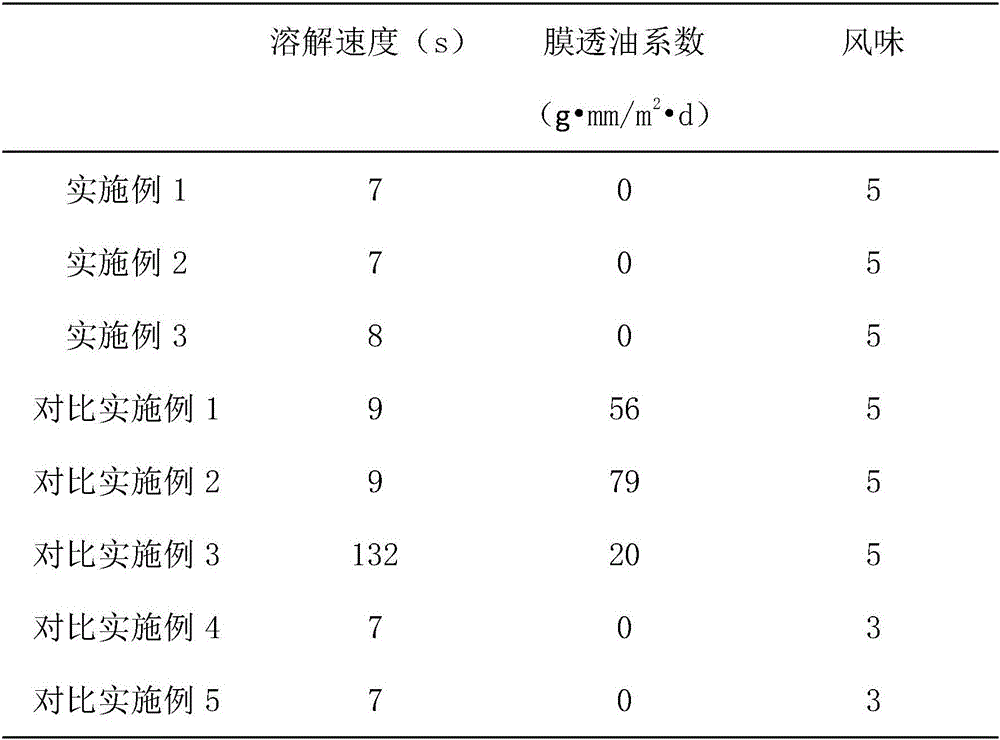

Examples

Embodiment 1

[0028] Weigh 2.4g of cornstarch, dissolve it in 200ml of water, and gelatinize it in a 70°C constant temperature water bath with a water bath stirrer for 30min to prepare a 1.2% (g / ml) uniform starch solution, and put the solution into an ultrasonic cleaner Degassing for 30 minutes for later use. Weigh 0.48g of sodium carboxymethyl cellulose, add it to the starch solution prepared in step 1, and keep stirring and swelling in a constant temperature water bath at 60°C for 30-40min, the mixed solution of sodium carboxymethyl cellulose and corn starch, put the solution Degassing in an ultrasonic cleaner for 30 minutes for later use. Mix cornstarch and sodium carboxymethyl cellulose mixed solution, zheer root extract and shallot extract in a volume ratio of 98:0.8:1.2, put the mixed solution on a magnetic stirrer and stir for 30 minutes, and then film-forming The solution was cast on a flat plate, the thickness of the coating film was controlled to be 1mm, placed in a drying oven ...

Embodiment 2

[0030] Weigh 4.5g of cornstarch, dissolve it in 300ml of water, and gelatinize it in a constant temperature water bath at 70°C with a water bath stirrer for 30min to prepare a 1.5% (g / ml) uniform starch solution, and put the solution into an ultrasonic cleaner Degassing for 30 minutes for later use. Weigh 0.9 g of sodium carboxymethyl cellulose, add it to the starch solution prepared in step 1, and swell in a constant temperature water bath at 60°C for 30-40 minutes while stirring continuously. The mixed solution of sodium carboxymethyl cellulose and corn starch, put the solution Degassing in an ultrasonic cleaner for 30 minutes for later use. Mix cornstarch and sodium carboxymethyl cellulose mixed solution, zheer root extract and shallot extract in a volume ratio of 98:1:1, put the mixed solution on a magnetic stirrer and stir for 30 minutes, and then film-forming The solution was cast on a flat plate, the thickness of the coating film was controlled to be 1mm, placed in a d...

Embodiment 3

[0032] Weigh 5.4g of cornstarch, dissolve it in 300ml of water, gelatinize in a constant temperature water bath at 70°C and stir with a water bath stirrer for 30min, prepare a uniform starch solution of 1.8% (g / ml), and put the solution into an ultrasonic cleaner Degassing for 30 minutes for later use. Weigh 0.9 g of sodium carboxymethyl cellulose, add it to the starch solution prepared in step 1, and swell in a constant temperature water bath at 60°C for 30-40 minutes while stirring continuously. The mixed solution of sodium carboxymethyl cellulose and corn starch, put the solution Degassing in an ultrasonic cleaner for 30 minutes for later use. Mix the cornstarch and sodium carboxymethyl cellulose mixed solution, Zheer root extract and shallot extract in a volume ratio of 98:1.2:0.8, put the mixed solution on a magnetic stirrer and stir for 30 minutes, and then film-forming The solution was cast on a flat plate, the thickness of the coating film was controlled to be 1mm, pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com