A kind of multi-layer structure alumina self-lubricating composite ceramic and preparation method thereof

A composite ceramic and multi-layer structure technology, applied in the field of multi-layer structure alumina self-lubricating composite ceramics and their preparation, can solve the problems that restrict the application and industrialization process of ceramic lubricating composite materials, poor reliability and damage resistance, and material mechanical properties. problems such as falling, to achieve excellent thermal shock stability, overcome the decline of mechanical properties, and high bending strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

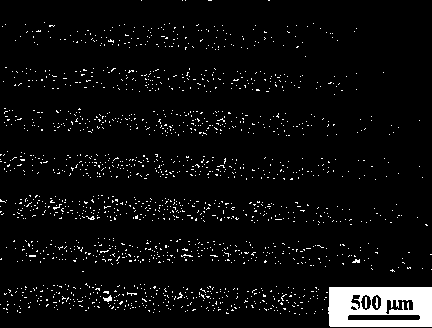

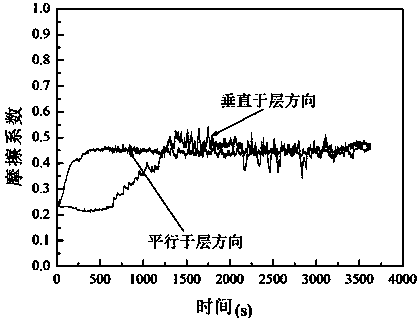

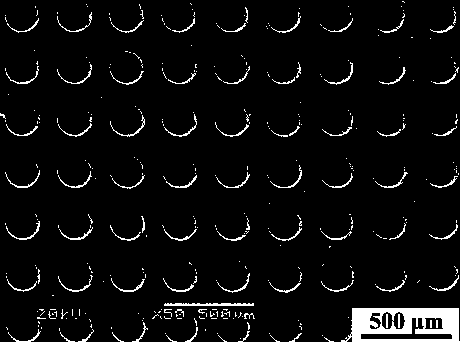

[0028] 300 g of alumina with a particle size ranging from 100 to 200 meshes was ball milled in an alcohol medium for 24 hours to obtain an ultrafine powder with a particle size of 50 nm to 200 nm; the above 0.69 g of alumina ultrafine powder and 0.23 g metal molybdenum powder was mixed in a vibrating mixer for 2 hours to obtain alumina-molybdenum mixed powder; the prepared alumina and alumina-molybdenum powder were alternately laid in a steel mold with a layer thickness of 1.50 mm. After the layup is completed, it is cold-pressed and preformed under a pressure of 150 MPa. Finally, put it into a hot-press furnace for sintering, the heating rate is 10 ℃ / min, the sintering temperature is 1400 ℃, the sintering pressure is 10 MPa, and the sintering time is 120 minutes. The whole sintering process is carried out under the protection of argon. Analysis of the finally obtained sintered samples shows that the layered structure is obvious, the average thickness of each layer is 277 μm, ...

Embodiment 2

[0030] 300 g of alumina with a particle size ranging from 100 to 200 meshes was ball milled in an alcohol medium for 24 hours to obtain an ultrafine powder with a particle size of 50 nm to 200 nm; the above 0.43 g of alumina ultrafine powder and 0.14 g metal molybdenum powder was mixed in a vibrating mixer for 2 hours to obtain alumina-molybdenum mixed powder; the prepared alumina and alumina-molybdenum powder were alternately laminated in a steel mold, and the layer thickness was 0.95 mm. After the layup is completed, it is cold-pressed and preformed under a pressure of 150 MPa. Finally, put it into a hot-press furnace for sintering, the heating rate is 5 °C / min, the sintering temperature is 1450 °C, the sintering pressure is 25 MPa, and the sintering time is 100 minutes. The whole sintering process is carried out under the protection of argon. The analysis of the finally obtained sintered samples shows that the layered structure is obvious, the average thickness of each laye...

Embodiment 3

[0032]300 g of alumina with a particle size range of 100-200 mesh was ball-milled in an alcohol medium for 24 hours to obtain an alumina ultra-fine powder with a particle size of 50 nm to 200 nm; the above 1.81 g of alumina ultra-fine powder and 0.60 g metal molybdenum powder was mixed in a vibrating mixer for 2 hours to obtain alumina-molybdenum mixed powder; the prepared alumina and alumina-molybdenum powder were alternately laminated in a steel mold, and the layer thickness was 4.00 mm. After the layup is completed, it is cold-pressed and preformed under a pressure of 150 MPa. Finally, put it into a hot-press furnace for sintering, the heating rate is 10 ℃ / min, the sintering temperature is 1350 ℃, the sintering pressure is 20 MPa, and the sintering time is 80 minutes. The whole sintering process is carried out under the protection of argon. The analysis of the finally obtained sintered samples shows that the layered structure is obvious, the average thickness of each layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com