Dye based on cellulose-based aerogel and preparation and dyeing method thereof

A technology of cellulose and airgel, applied in the field of textile materials, to achieve the effects of improving stability, improving dyeing performance, and increasing dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

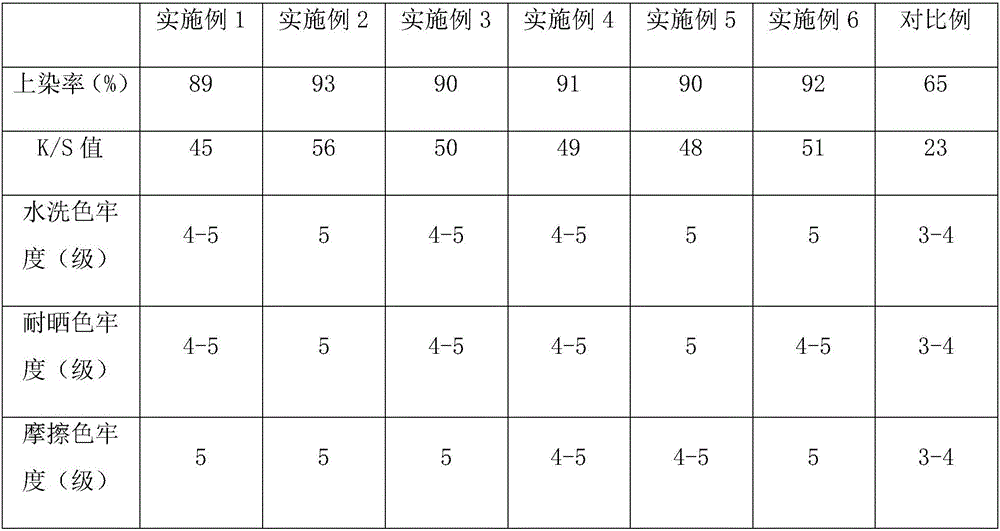

Examples

Embodiment 1

[0027] (1) The mineral dye azurite is crushed, and the balls are formed into a micronano-scale azurite powder with a particle size of 0.5 μm. The material-liquid ratio is 1g:25ml, and the micro-nano-scale azurite powder is added to the oxalic acid solution , heat and stir at 70°C until dissolved, add 10ml of ammonium salt solution, heat and stir at 75°C for 20min to form natural mineral dyes, wherein the mass fraction of mineral dyes is 0.5%.

[0028] (2) Wash the fresh leaves of the plant dye horse indigo, cut them into pieces with a length of less than 5mm, place them in deionized water with a material-to-liquid ratio of 1g:30ml, adjust the pH value to 3, and adjust the temperature to 50°C. Ultrasonic treatment was performed for 30 min at a power of 500 W, and the filter residue was removed by filtration to obtain a natural vegetable dye, wherein the mass fraction of the vegetable dye was 15%.

[0029] (3) Mix natural mineral dyes with natural plant dyes, add quaternary ammo...

Embodiment 2

[0031] (1) The mineral dye azurite is crushed, and the ball is formed into a micronano-scale azurite powder with a particle size of 1 μm. The material-liquid ratio is 1g:30ml, and the micro-nano-scale azurite powder is added to the oxalic acid solution , heated and stirred at 80° C. until dissolved, added to 15 ml of ammonium salt solution, heated and stirred at 80° C. for 30 minutes to form natural mineral dyes, wherein the mass fraction of mineral dyes is 1%.

[0032] (2) Wash the fresh leaves of the plant dye horse indigo, cut them into pieces with a length of less than 5mm, place them in deionized water at a material-to-liquid ratio of 1g:50ml, adjust the pH value to 35, and adjust the temperature to 60°C. Ultrasonic treatment was performed for 60 min at a power of 500 W, and the filter residue was removed by filtration to obtain a natural vegetable dye, wherein the mass fraction of the vegetable dye was 20%.

[0033] (3) Mix natural mineral dyes with natural plant dyes, a...

Embodiment 3

[0035] (1) The mineral dye azurite is crushed, and the ball is formed into a micronano-scale azurite powder with a particle size of 0.8 μm. The material-liquid ratio is 1g:28ml, and the micro-nano-scale azurite powder is added to the oxalic acid solution , heat and stir at 75°C until dissolved, add 13ml of ammonium salt solution, heat and stir at 78°C for 25min to form natural mineral dyes, wherein the mass fraction of mineral dyes is 0.7%.

[0036] (2) Wash the fresh leaves of the plant dye horse indigo, cut them into pieces with a length of less than 5mm, place them in deionized water at a ratio of 1g to 45ml, adjust the pH value to 4, and adjust the temperature to 55°C. Ultrasonic treatment was performed for 45 minutes at a power of 500 W, and the filter residue was removed by filtration to obtain a natural vegetable dye, wherein the mass fraction of the vegetable dye was 17%.

[0037](3) Mix natural mineral dyes with natural plant dyes, add quaternary ammonium salt surfact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com