A kind of dye based on cellulose-based airgel and its preparation and dyeing method

A cellulose and aerogel technology, applied in the field of textile materials, to achieve the effect of enhancing color fastness and color, improving stability and increasing dyeing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

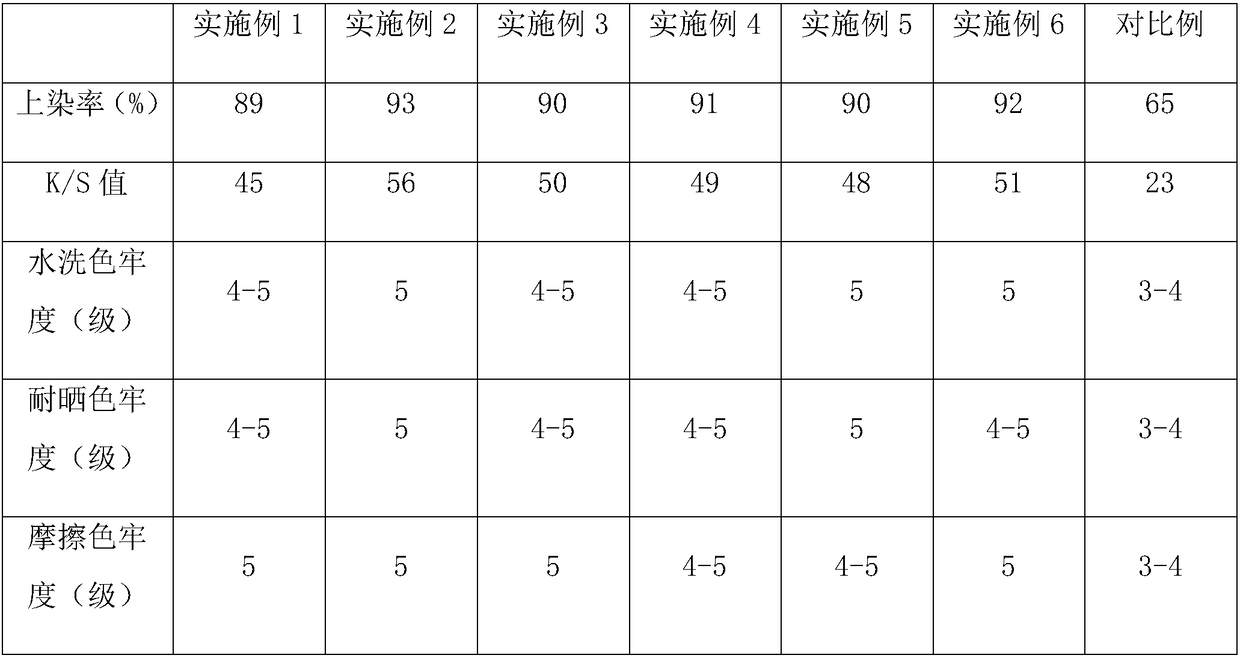

Examples

Embodiment 1

[0027] (1) The mineral dye azurite is crushed, and the balls are formed into a micronano-scale azurite powder with a particle size of 0.5 μm. The material-liquid ratio is 1g:25ml, and the micro-nano-scale azurite powder is added to the oxalic acid solution , heat and stir at 70°C until dissolved, add 10ml of ammonium salt solution, heat and stir at 75°C for 20min to form natural mineral dyes, wherein the mass fraction of mineral dyes is 0.5%.

[0028] (2) Wash the fresh leaves of the plant dye horse indigo, cut them into pieces with a length of less than 5mm, place them in deionized water with a material-to-liquid ratio of 1g:30ml, adjust the pH value to 3, and adjust the temperature to 50°C. Ultrasonic treatment was performed for 30 min at a power of 500 W, and the filter residue was removed by filtration to obtain a natural vegetable dye, wherein the mass fraction of the vegetable dye was 15%.

[0029] (3) Mix natural mineral dyes with natural plant dyes, add quaternary ammo...

Embodiment 2

[0031] (1) The mineral dye azurite is crushed, and the ball is formed into a micronano-scale azurite powder with a particle size of 1 μm. The material-liquid ratio is 1g:30ml, and the micro-nano-scale azurite powder is added to the oxalic acid solution , heated and stirred at 80° C. until dissolved, added to 15 ml of ammonium salt solution, heated and stirred at 80° C. for 30 minutes to form natural mineral dyes, wherein the mass fraction of mineral dyes is 1%.

[0032] (2) Wash the fresh leaves of the plant dye horse indigo, cut them into pieces with a length of less than 5mm, place them in deionized water at a material-to-liquid ratio of 1g:50ml, adjust the pH value to 35, and adjust the temperature to 60°C. Ultrasonic treatment was performed for 60 min at a power of 500 W, and the filter residue was removed by filtration to obtain a natural vegetable dye, wherein the mass fraction of the vegetable dye was 20%.

[0033] (3) Mix natural mineral dyes with natural plant dyes, a...

Embodiment 3

[0035] (1) The mineral dye azurite is crushed, and the ball is formed into a micronano-scale azurite powder with a particle size of 0.8 μm. The material-liquid ratio is 1g:28ml, and the micro-nano-scale azurite powder is added to the oxalic acid solution , heat and stir at 75°C until dissolved, add 13ml of ammonium salt solution, heat and stir at 78°C for 25min to form natural mineral dyes, wherein the mass fraction of mineral dyes is 0.7%.

[0036] (2) Wash the fresh leaves of the plant dye horse indigo, cut them into pieces with a length of less than 5mm, place them in deionized water at a ratio of 1g to 45ml, adjust the pH value to 4, and adjust the temperature to 55°C. Ultrasonic treatment was performed for 45 minutes at a power of 500 W, and the filter residue was removed by filtration to obtain a natural vegetable dye, wherein the mass fraction of the vegetable dye was 17%.

[0037](3) Mix natural mineral dyes with natural plant dyes, add quaternary ammonium salt surfact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com