Preparation method for antibacterial paper

An antibacterial paper and pulp technology, applied in special paper, paper, papermaking, etc., can solve problems such as paper improvement, and achieve the effect of preventing mildew, reducing cost, and having good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

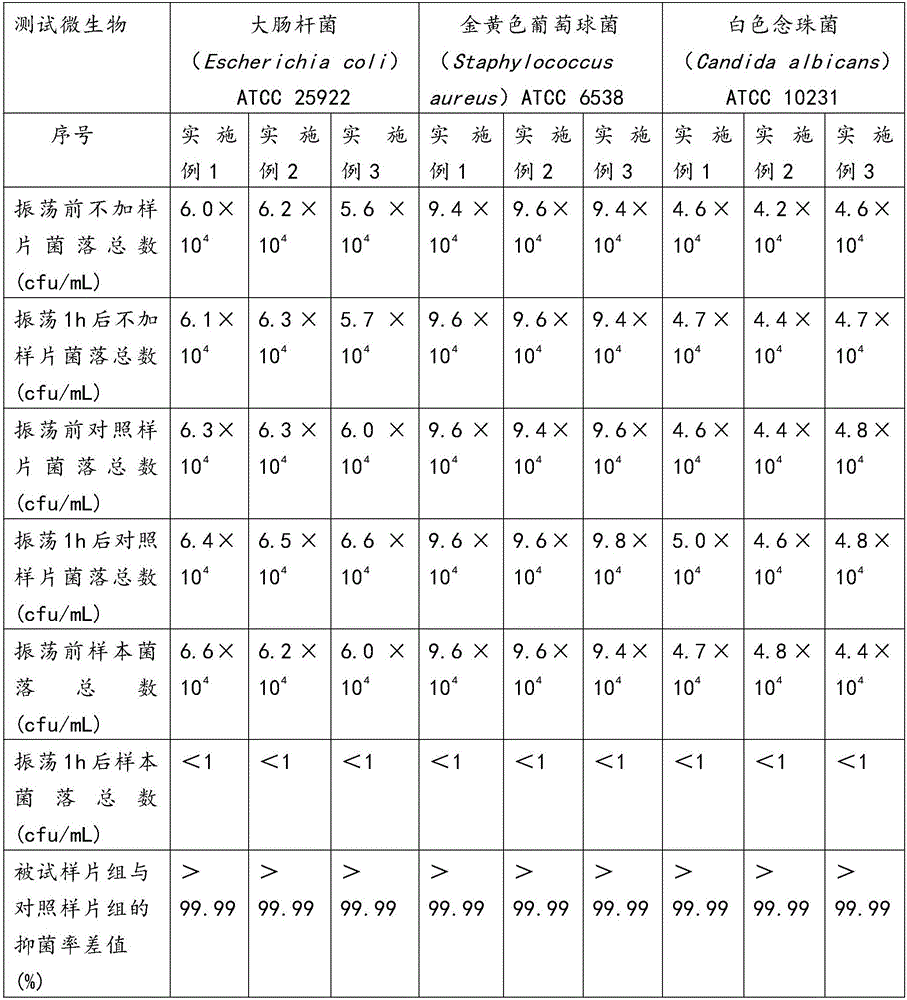

Examples

Embodiment 1

[0032] A preparation method for antibacterial paper, comprising the following steps:

[0033](1) taking coniferous wood fiber raw materials and dissociating into uncolored pulp through mechanical pulping method, the content of the total dry weight of slurry in the uncolored pulp is 20%;

[0034] (2) Cut bamboo or waste materials such as bamboo leaves and bamboo joints to 10mm, then dry at 70°C for 20min to make the moisture content 10%; grind the baked above-mentioned materials to 20 meshes to obtain bamboo powder ;Put the bamboo powder into the extraction kettle, pour into the ethanol solution with a volume concentration of 38%, wherein the volume ratio of the ethanol solution, bamboo powder and the reaction kettle is 3:1:5, and the two ends of the extraction kettle are fixed with stacked The degreased gauze obtained after installing the kettle cover of the reaction kettle is a good extraction kettle;

[0035] (3) Fix the loaded extraction kettle in the heating box, close th...

Embodiment 2

[0039] A preparation method for antibacterial paper, comprising the following steps:

[0040] (1) get bamboo pulp leftovers (bamboo leaves, bamboo joints) to be dissociated into natural color pulp through chemical chemical mechanical pulping method, and the content of the total dry weight of slurry in the described natural color pulp is 25%;

[0041] (2) Cut bamboo or waste materials such as bamboo leaves and bamboo joints to 18mm, then dry at 75°C for 20min to make its moisture content 8%; grind the above-mentioned materials that have been baked to 40 meshes to obtain bamboo powder ;Put the bamboo powder into the extraction kettle, pour into the ethanol solution with a volume concentration of 40%, wherein the volume ratio of the ethanol solution, bamboo powder and the reaction kettle is 3:1:5, and the two ends of the extraction kettle are fixed with stacked The degreased gauze obtained after installing the kettle cover of the reaction kettle is a good extraction kettle;

[0...

Embodiment 3

[0046] A preparation method for antibacterial paper, comprising the following steps:

[0047] (1) Get coniferous wood fiber raw materials, hardwood fiber raw materials, grass plant fiber raw materials, bast fiber raw materials, seed hair fiber raw materials and waste paper fiber raw materials mixed in equal proportions to dissociate into natural color pulp through chemical mechanical pulping method, The content of the total dry weight of the slurry in the natural color pulp is 30%;

[0048] (2) Cut bamboo or waste materials such as bamboo leaves and bamboo joints to 25mm, then dry at 80°C for 20min to make its moisture content 6%; grind the above-mentioned materials to 60 mesh to obtain bamboo powder ;Put the bamboo powder into the extraction kettle, pour into the ethanol solution with a volume concentration of 42%, wherein the volume ratio of the ethanol solution, bamboo powder and the reaction kettle is 3:1:5, and the two ends of the extraction kettle are fixed with stacked ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com