High-precision LNG filling station using integrated optical fiber sensor

A fiber optic sensor and gas filling station technology, applied in the container discharge method, the equipment loaded into the pressure vessel, the geometry/arrangement/size of the container structure, etc., can solve the problem of measurement, statistics, management lag, and difficult management of the purchase process , Measuring equipment measurement errors and other issues, to achieve good market application prospects, safe and reliable use, easy to bend effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

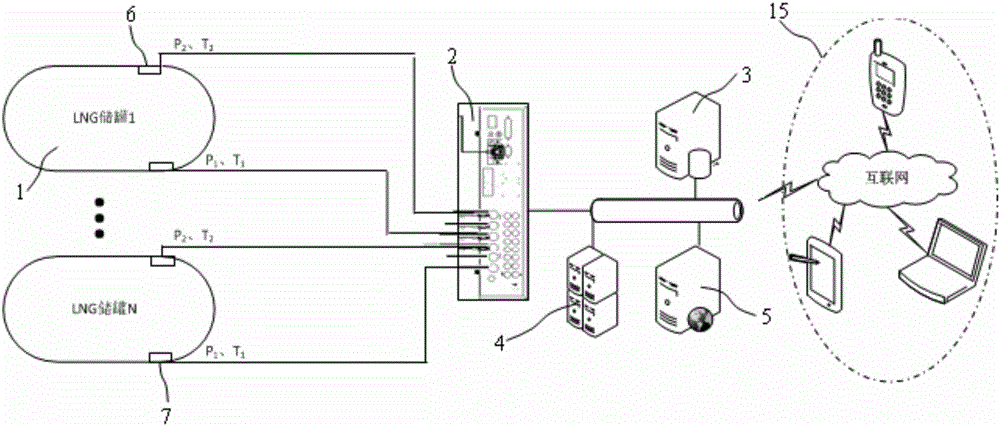

[0029] Embodiment: A high-precision LNG refueling station adopting an integrated optical fiber sensor, comprising: a liquefied natural gas storage tank 1, a modem 2, a database server 3, an application server 4, a WEB server 5, a remote monitoring terminal 15, respectively The first F-P cavity pressure sensor 6 and the second F-P cavity pressure sensor 7 installed on the top and bottom of the liquefied natural gas storage tank 1, the database server 3 is connected to the modem 2, and the application server 4 and the WEB server 5 are both Connect to database server 3;

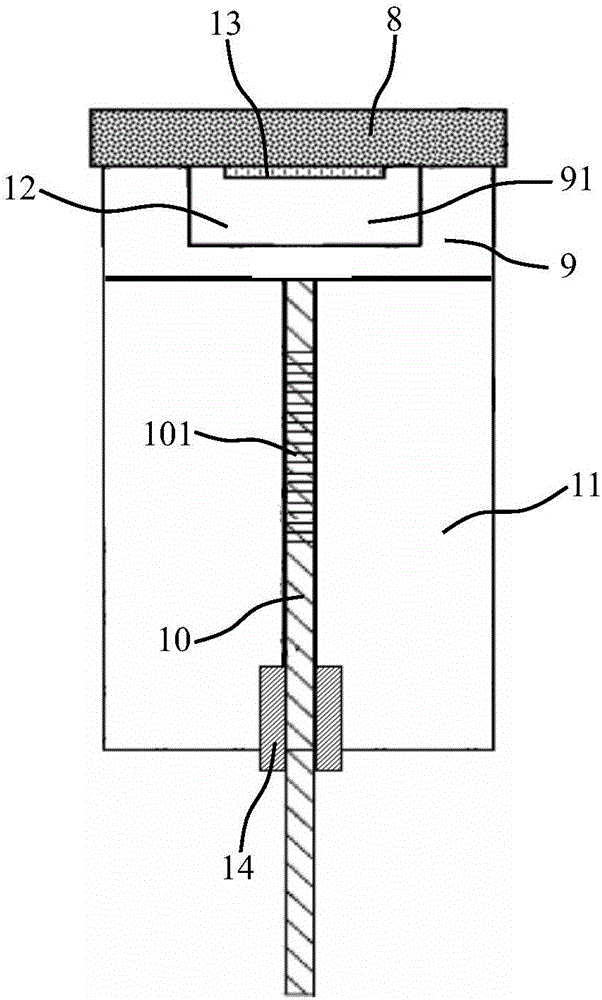

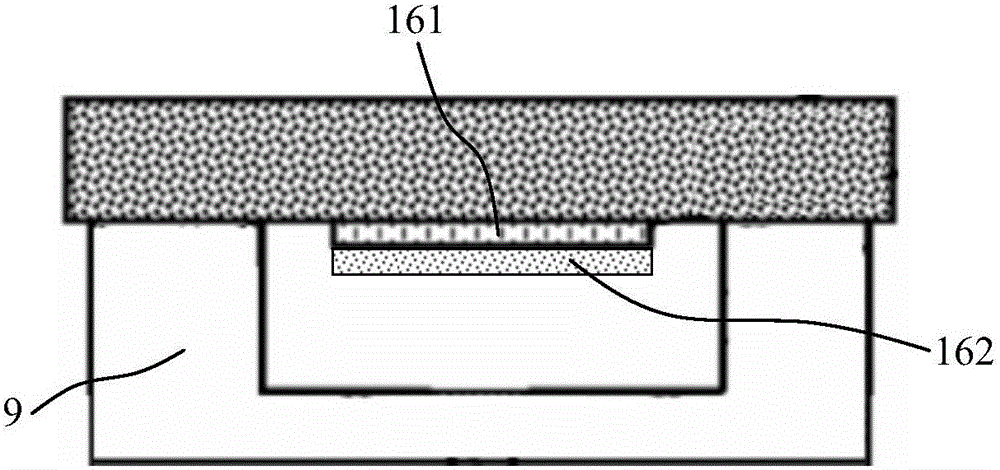

[0030] The first F-P cavity pressure sensor 6 and the second F-P cavity pressure sensor 7 further include a diaphragm 8, a cavity body 9, a light guide fiber 10 and a collimator 11, and a groove 91 is opened on the upper surface of the cavity body 9, The groove 91 is covered with the diaphragm 8 and forms a vacuum cavity 12. The upper end surface of the collimator 11 is bonded to the bottom of the cavity body 9,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com