Distributed type natural gas heating device

A heating device, distributed technology, applied in the field of a device for heating liquid by steel wire surface treatment, can solve the problems of high cost, unstable temperature, uncontrollable tank temperature, etc., to extend the length and realize the effect of safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

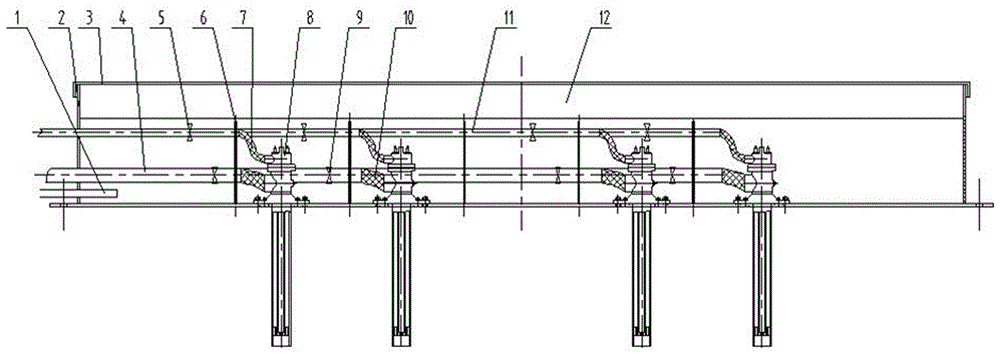

[0024] A kind of distributed natural gas heating device of the present invention is described in further detail below in conjunction with accompanying drawing:

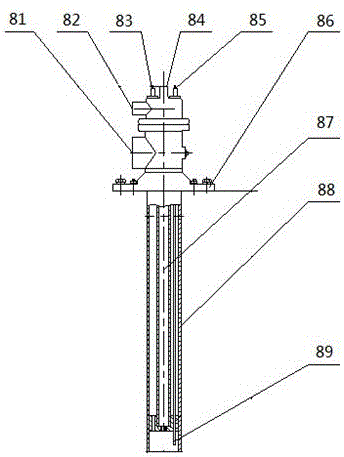

[0025] The invention according to figure 1 , 2 Among them, it consists of blowing pipe 1, integrated box body 2, integrated box body cover 3, combustion-supporting air supply pipe 4, gas electric control cut-off valve 5, fixed plate 6, gas glass metal hose 7, burner 8, combustion-supporting air duct Composed of electric control cut-off valve 9, air duct glass metal hose 10, gas pipeline 11 and cable channel 12; integrated box cover 3 is arranged above integrated box body 2, and burner 8 is arranged inside, and burner 8 is connected to There are gas glass metal hose 7 and air duct glass metal hose 10, the gas glass metal hose 7 is connected to the gas pipeline 11, and the gas pipeline 11 is provided with a gas electric control shut-off valve 5, the air duct glass metal hose 10 and the combustion-supporting delivery T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com