Self-repairable photosensitive weld-retarding dry film

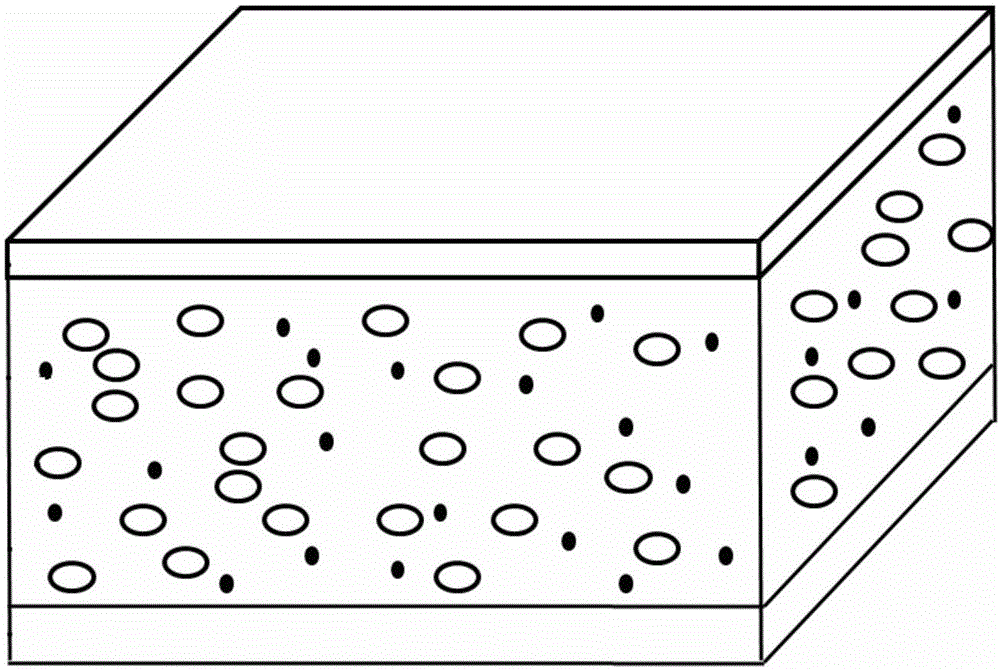

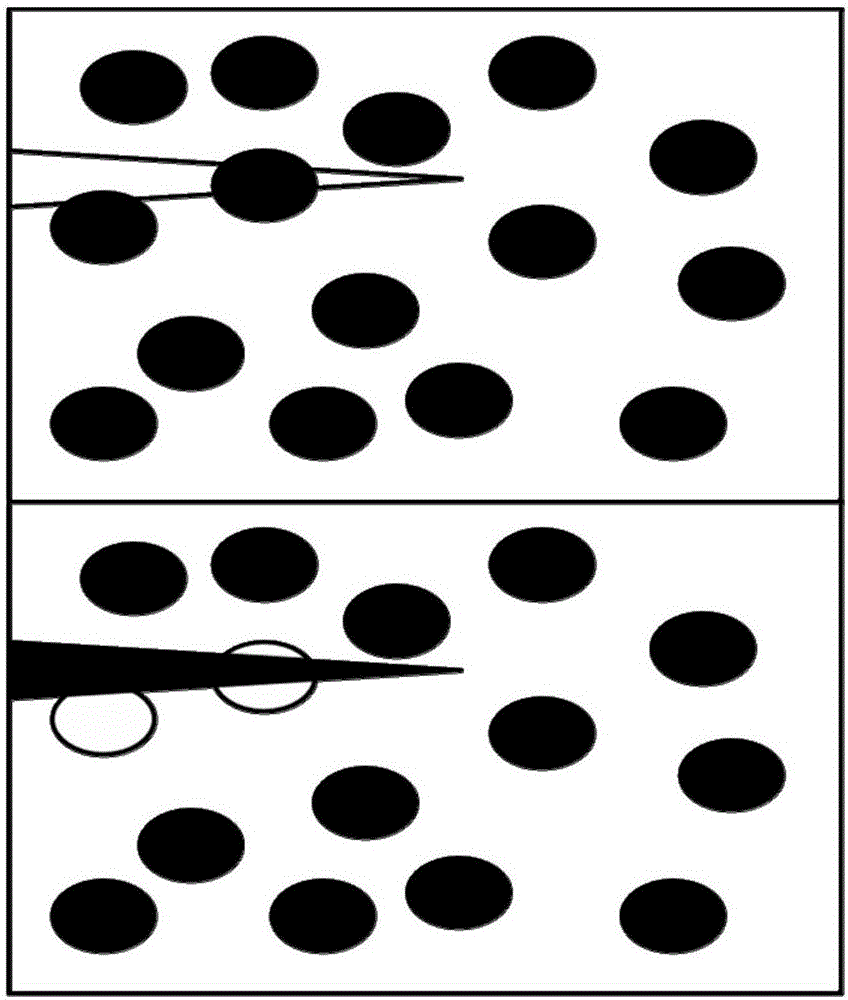

A solder mask dry film, self-healing technology, applied in photosensitive materials, optics, opto-mechanical equipment, etc. for opto-mechanical equipment, can solve the problems affecting the production yield of circuit boards, circuit short-circuits, etc., to ensure solder-resistance. and insulation, prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

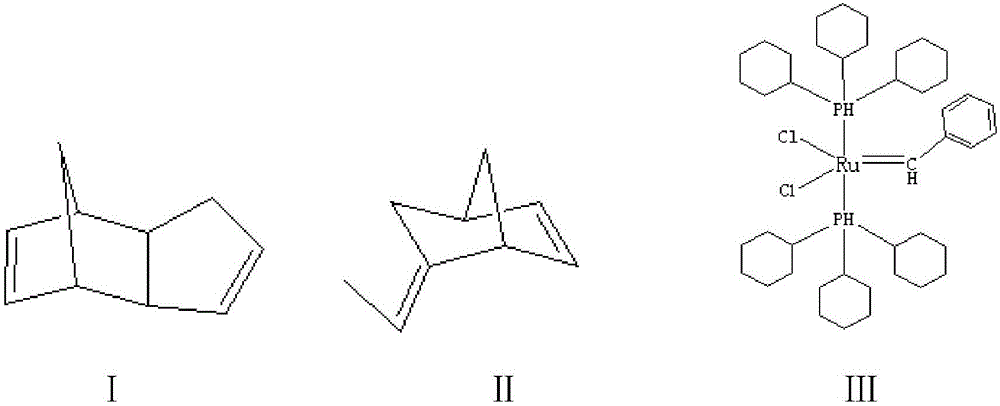

Method used

Image

Examples

Embodiment 1-6

[0044] Hereinafter, the preparation method of the sample for evaluation of an Example and a comparative example, the evaluation method of a sample, and an evaluation result are demonstrated.

[0045] The production method is as follows:

[0046] First, the following alkali-soluble polymers are prepared.

[0047] Under a nitrogen atmosphere, add 120 milliliters of methyl ethyl ketone to a 500 milliliter four-necked flask equipped with a heating device, a stirring paddle, a serpentine condenser, a constant pressure dropping funnel and a thermometer, and add all the monomers used in the polymer formula. body, turn on the stirring device, and raise the temperature of the heating device to 80°C. Next, under a nitrogen atmosphere, a solution of 0.3 g of azobisisobutyronitrile in 30 ml of butanone was slowly added dropwise to the reaction flask, and the dropping process lasted for about 1.5 hours. After the dropwise addition was completed, the insulation was continued for 4 hours. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com